Gravity casting mold for end cover of new energy water cooling motor shell and casting process thereof

A water-cooled motor and gravity casting technology, which is applied in the manufacture of tools, casting molding equipment, casting molds, etc., can solve the problems of low work intensity, complex gravity casting process design structure, poor product quality, etc., and achieve the effect of shortening the flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

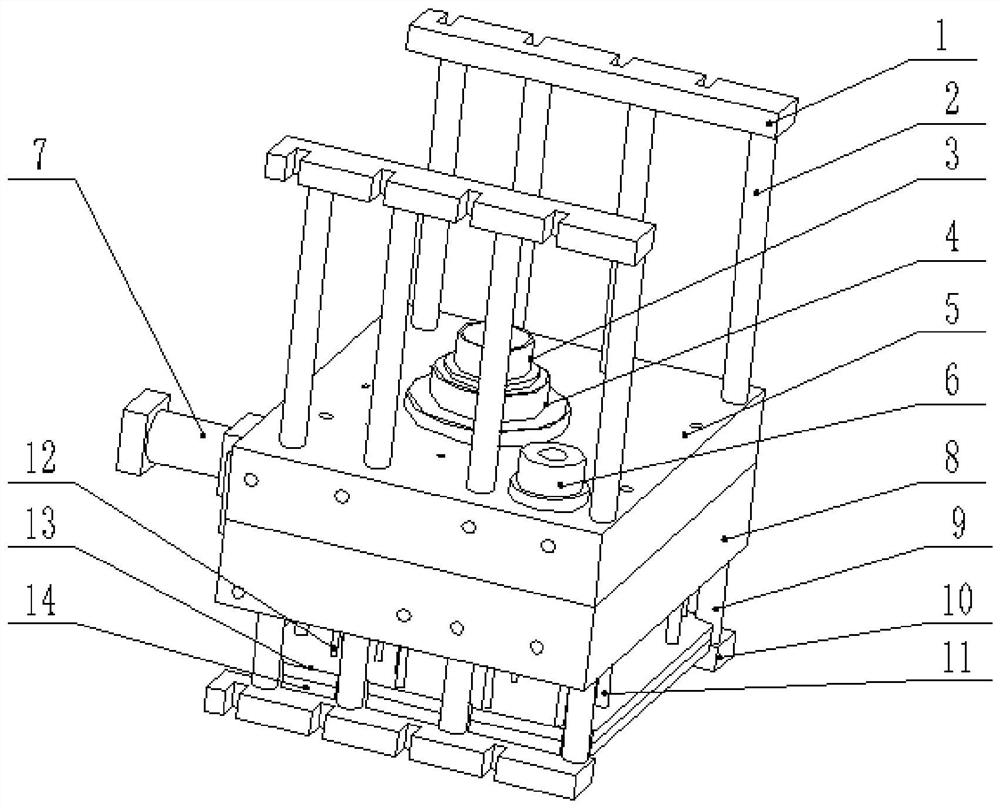

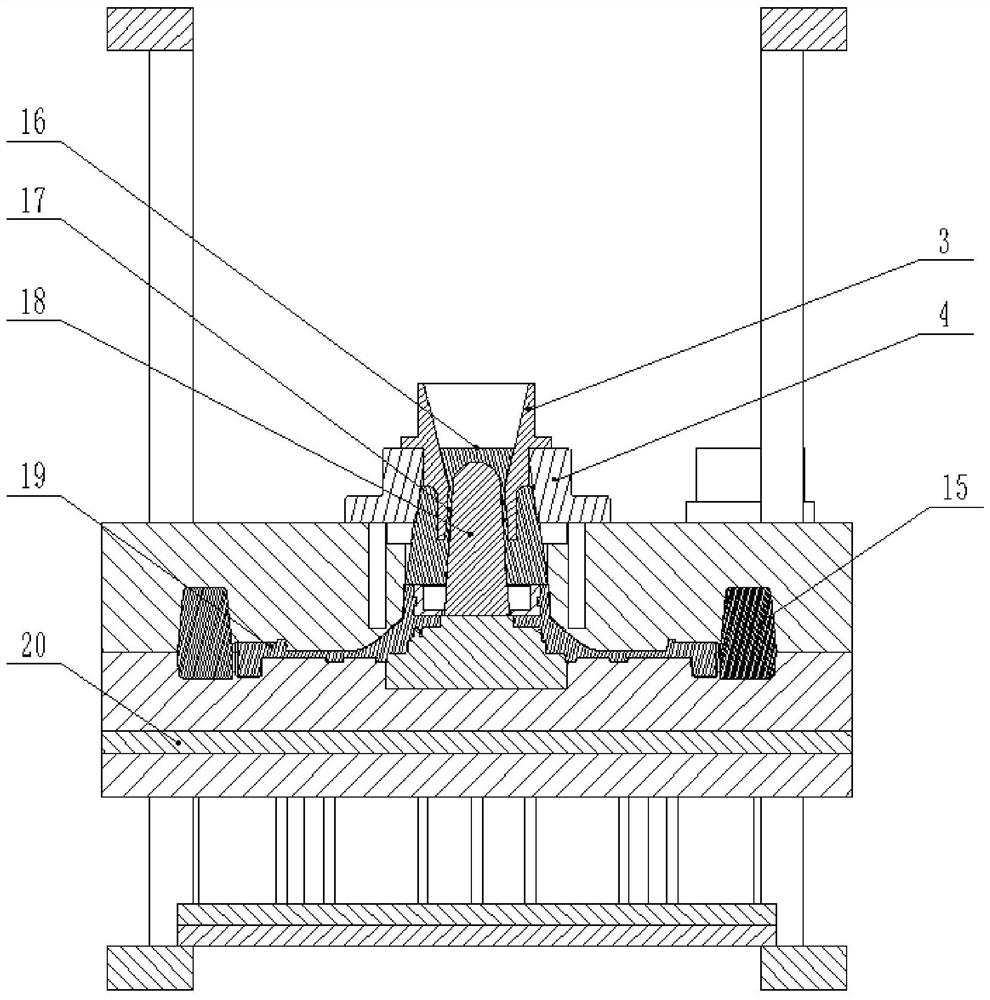

[0025] Such as Figure 1-2 As shown, the gravity casting mold for the end cover of the new energy water-cooled motor housing includes an upper mold 5 and a lower mold 8, and the upper mold 5 and the lower mold 8 form a mold cavity 19 after mold closing, and the upper mold 5 is provided with The upper mold fixed plate 1, the upper mold fixed plate 1 is fixedly connected with the upper mold 5 through the upper mold connecting rod 2, the center of the upper mold 5 is provided with a gate 16, and the gate 16 is surrounded by a sprue sleeve 3, and the sprue sleeve 3 is installed on the sprue sleeve positioning ring 4, the sprue sleeve positioning ring 4 is fixed on the upper mold 5, and the edge of the upper mold 5 is provided with an open riser 6; the lower mold 8 is provided with a lower mold fixing plate 10, and the lower mold The mold fixing plate 10 is fixedly connected with the lower mold 8 through the lower mold connecting rod 9, and an ejection system is provided under the ...

Embodiment 2

[0027] Such as Figure 1-2 As shown, the gravity casting mold of the end cover of the new energy water-cooled motor housing in Example 1 is used for casting, which specifically includes the following steps:

[0028] In the first step, the upper mold 5 and the lower mold 8 are subjected to surface sandblasting on the parts corresponding to the product forming surfaces;

[0029] In the second step, the upper mold 5 and the lower mold 8 are preheated to 290°C-300°C, and then the surface of the forming surface is sprayed with heat-insulating and high-heat-retaining paint;

[0030] The third step is to close the hydraulic core pulling 7 in place, close the upper mold 5 and the lower mold 8, heat the mold to 360°C-380°C, and then melt the natural gas aluminum melting furnace to obtain A356 aluminum liquid, aluminum liquid The temperature is controlled at 700°C-720°C, and the molten aluminum is poured directly into the sprue sleeve 3 of the mold through a scoop, and the molten alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com