Novel grid alloy, positive plate grid containing novel grid alloy and lead-acid storage battery

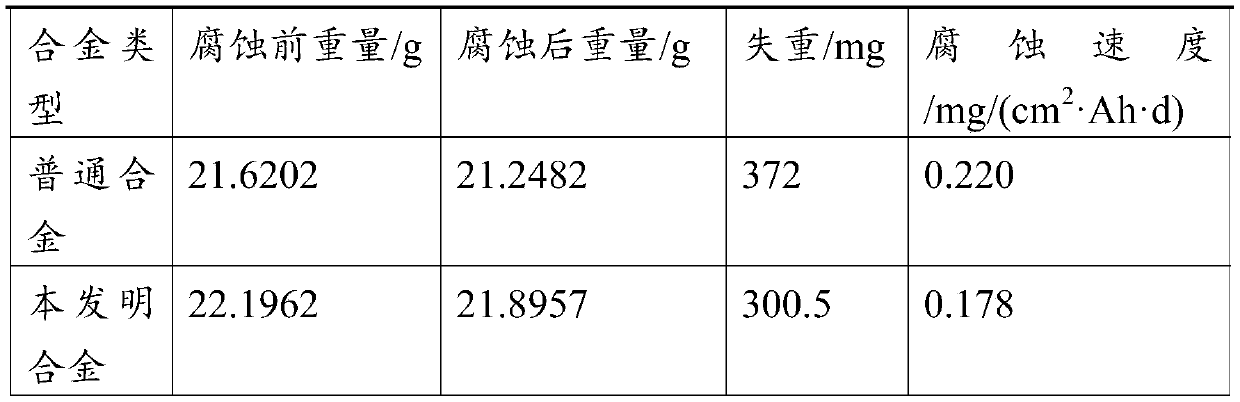

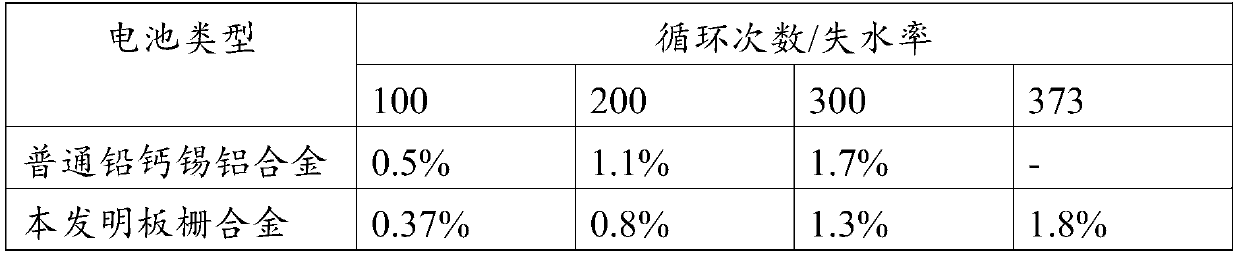

A technology for lead-acid batteries and positive plates, applied in the direction of electrode carriers/collectors, etc., can solve the problems of unsatisfactory corrosion resistance of lead-calcium alloys, achieve good machining performance, improve elongation, and improve corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment prepares a grid alloy and a positive plate grid, wherein the grid alloy contains 0.085% calcium, 0.6% tin, 0.02% aluminum, 0.03% cerium, 0.03% copper and 0.02% by weight. % sodium, the balance lead. The purity of the metal raw material selected in this embodiment is at least 99.99%.

[0026] A graphite crucible electrolytic cell is selected, graphite is used as the anode, and molybdenum rod is used as the cathode. To an electrolyte system containing 70 g of cerium fluoride, 15 g of lithium fluoride and 15 g of barium fluoride was added a mixture of 3.69 g of cerium oxide and 3.78 g of aluminum oxide. Choose 2.0A / cm 2 The anode current density, 20A / cm 2 The cathodic current density of the molten salt electrolysis system was subjected to molten salt electrolysis eutectoid, the electrolysis temperature was 900°C, and a molybdenum crucible was used to receive the prepared 5g cerium-aluminum master alloy, which contained about 3g of cerium and about 2g of ...

Embodiment 2

[0031] This embodiment prepares a grid alloy and a positive plate grid, wherein the grid alloy contains 0.08% calcium, 0.8% tin, 0.02% aluminum, 0.03% cerium, 0.035% copper and 0.025% by weight. % sodium, the balance lead. The purity of the metal raw material selected in this embodiment is at least 99.99%.

[0032] A graphite crucible electrolytic cell is selected, graphite is used as the anode, and molybdenum rod is used as the cathode. To an electrolyte system containing 70 g of cerium fluoride, 15 g of lithium fluoride and 15 g of barium fluoride was added a mixture of 3.69 g of cerium oxide and 3.78 g of aluminum oxide. Choose 2.0A / cm 2 The anode current density, 20A / cm 2 The cathodic current density of the molten salt electrolysis system was subjected to molten salt electrolysis eutectoid, the electrolysis temperature was 900°C, and a molybdenum crucible was used to receive the prepared 5g cerium-aluminum master alloy, which contained about 3g of cerium and about 2g of...

Embodiment 3

[0037] This embodiment prepares a grid alloy and a positive plate grid, wherein the grid alloy contains 0.085% calcium, 0.45% tin, 0.03% aluminum, 0.03% cerium, 0.035% copper and 0.02% by weight. % sodium, the balance lead. The purity of the metal raw material selected in this embodiment is at least 99.99%.

[0038] A graphite crucible electrolytic cell is selected, graphite is used as the anode, and molybdenum rod is used as the cathode. To an electrolyte system containing 70 g of cerium fluoride, 15 g of lithium fluoride and 15 g of barium fluoride was added a mixture of 3.69 g of cerium oxide and 5.67 g of aluminum oxide. Choose 2.0A / cm 2 The anode current density, 20A / cm 2 The cathodic current density of the molten salt electrolysis system is carried out with molten salt electrolytic eutectoid, the electrolysis temperature is 900 ° C, and the prepared 5 g cerium aluminum master alloy is received in a molybdenum crucible, which contains about 3 g of cerium and about 3 g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com