LTCC raw material tape material, LTCC substrate and preparation method

A technology of raw material tape and substrate, applied in the field of LTCC substrate and preparation, LTCC raw material tape material, can solve the problem of difficult to increase, mechanical strength and impact resistance are not enough to meet the application requirements of harsh conditions, unable to obtain high-strength LTCC substrate, etc. problem, to achieve the effect of increasing density, increasing strength, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a kind of preparation method of above-mentioned LTCC raw tape material, and the preparation method of LTCC raw tape material comprises the following steps:

[0046] S1, preparing CaAlSi glass ceramics;

[0047] S2, prepare sintering aid;

[0048] S3, CaAlSi glass-ceramic, sintering aid, Al 2 o 3 Ceramic, ZrO 2 Ceramics are added to the ball mill according to the mass ratio, then add solvent and dispersant and continue ball milling for 2 to 4 hours, such as 2 hours, 2.5 hours, 3 hours, 3.5 hours, 4 hours, etc., add binder and plasticizer, and then ball mill for 2 to 4 hours , such as 2h, 2.5h, 3h, 3.5h, 4h, etc., after vacuum defoaming and tape casting, the LTCC raw tape material is obtained.

[0049] Concretely, adding plasticizer and binding agent can make cast slurry have cohesiveness and toughness, but in the present invention about plasticizer, binding agent specific composition and specific addition amount, do not do too much...

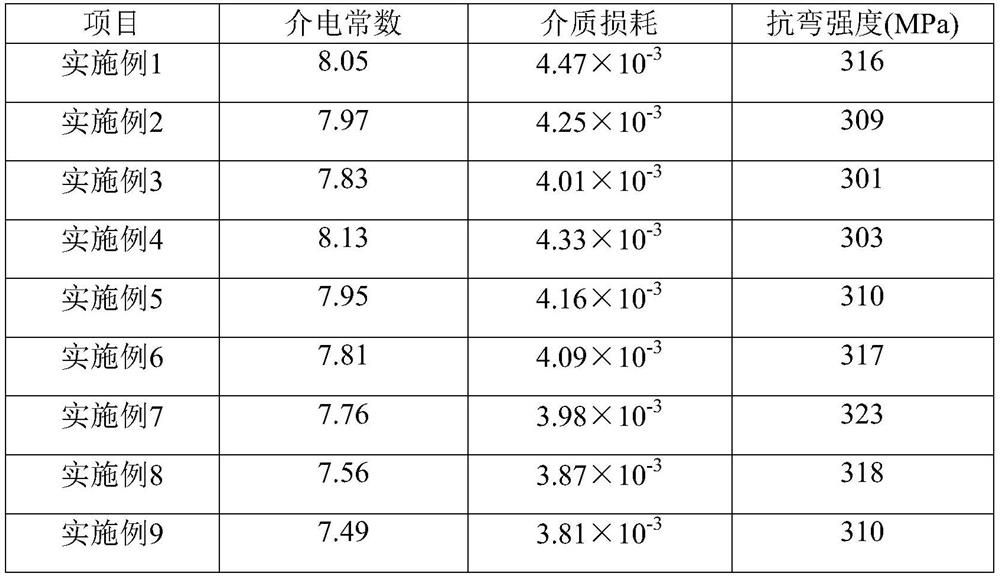

Embodiment 1

[0068] The present embodiment provides a kind of preparation method of LTCC raw tape material, comprises the following steps:

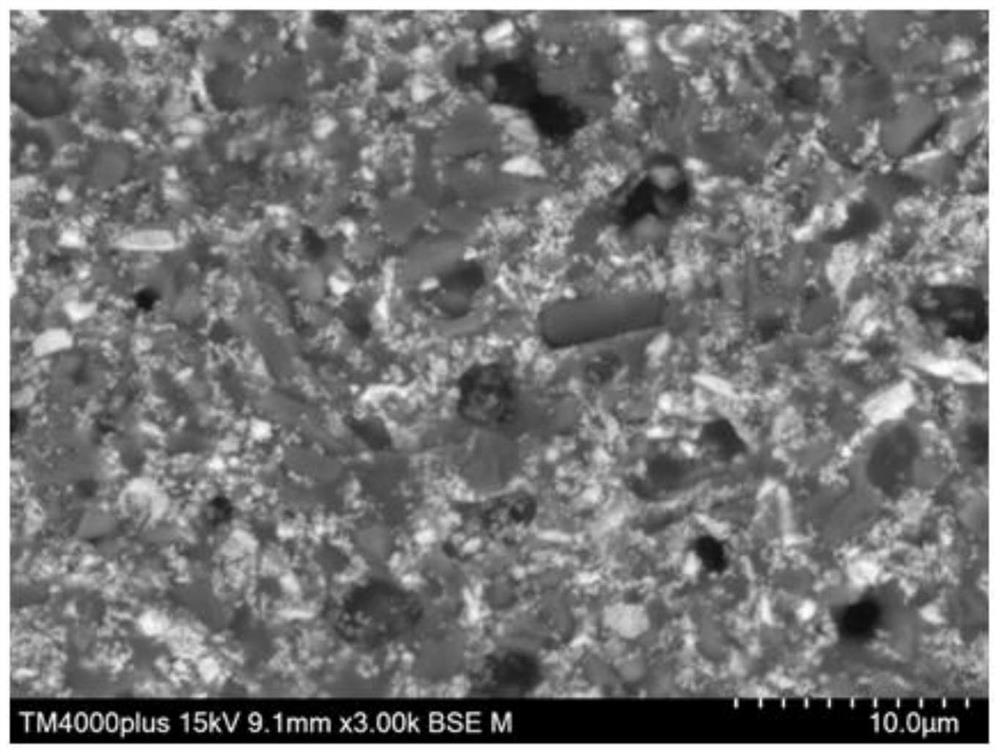

[0069] S1, the CaCO 3 、Al 2 o 3 , SiO 2 、H 3 BO 3 , ZrO 2 、TiO 2 , La 2 o 3 Mix according to the proportion, melt at 1450-1600°C for 3 hours, melt into glass liquid and then quench, then sand mill to control the powder particle size, dry at 100-120°C, filter through 400 mesh sieve to obtain D50 particle size 3.5-4.0μm CaAlSi glass-ceramics;

[0070] S2, the BaCO 3 、H 3 BO 3 , ZnO, SiO 2 Mix according to the proportion, melt at 1100-1200°C for 3 hours, melt into glass liquid and then quench, then sand mill to control the powder particle size, dry, and filter through 400 mesh sieve to obtain BBZS glass;

[0071] S3, CaAlSi glass ceramics, BBZS glass, Al 2 o 3 Ceramic, ZrO 2 The ceramics are added to the ball mill according to the mass ratio, and then the solvent and the dispersant are added to continue the ball milling and mixing for 3 ...

Embodiment 2

[0075] This embodiment provides a preparation method of LTCC raw tape material. The difference between the preparation method and Embodiment 1 is: CaAlSi glass-ceramic, BBZS glass, Al 2 o 3 Ceramic, ZrO 2 The proportioning between ceramics is different, in the present embodiment, by the mass percentage of inorganic material, inorganic material comprises: the Al of 36wt% 2 o 3 Ceramic, 34wt% ZrO 2 Ceramics, 28wt% CaAlSi glass-ceramic and 2wt% BBZS glass; other methods and steps are the same as in Example 1, and will not be repeated here.

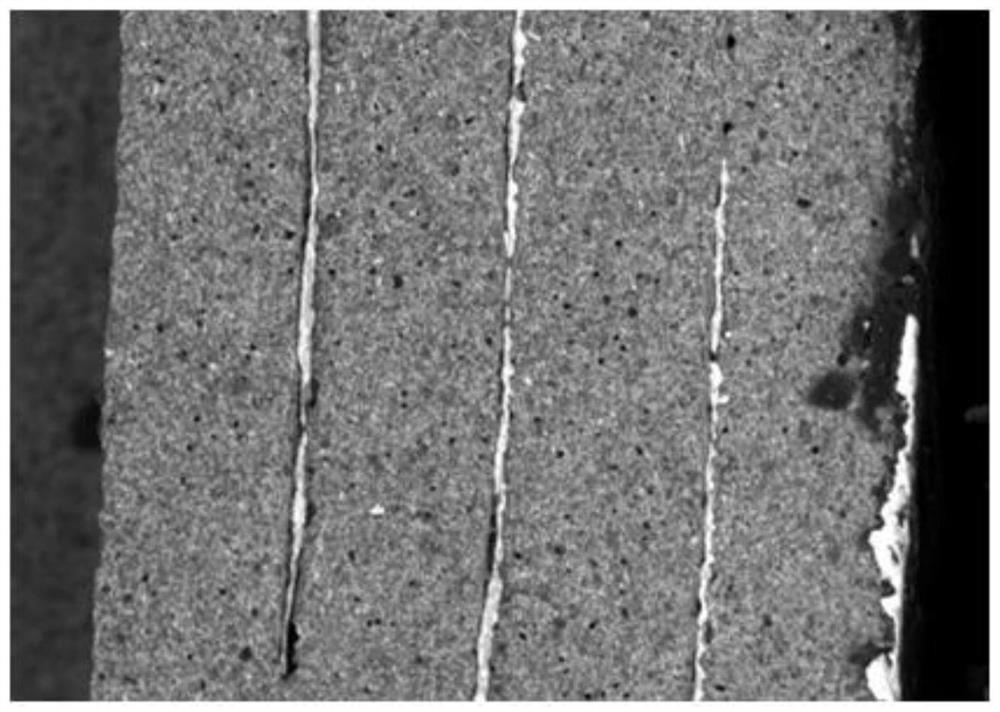

[0076] This embodiment provides a method for preparing an LTCC substrate, which includes the following steps: providing the LTCC raw tape material prepared in this embodiment; laminating multiple layers of the LTCC raw tape material, and forming it by vacuuming and isostatic pressing. Green body, put the green body into the sintering furnace, raise the temperature from room temperature to 500 °C at a rate of 1 °C / min, keep it warm for 3 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com