Gas-based shaft-furnace direct-reduction smelting method for high-chromium-content vanadium-titanium magnetite

A technology of vanadium-titanium magnetite and vanadium-titanium magnet, which is applied in shaft furnaces, furnaces, furnace types, etc., can solve the problems of low comprehensive utilization rate, long blast furnace smelting process, and low grade, and achieve easy operation and control, clean Efficient separation and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

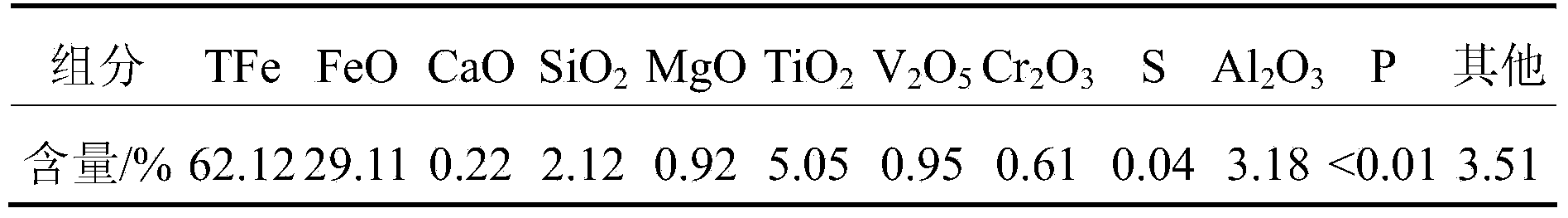

[0016] The chemical composition of a high-chromium vanadium-titanium magnetite and experimental bentonite are listed in Table 1 and Table 2, respectively, by weight percentage.

[0017] Table 1 Chemical composition of high chromium type vanadium-titanium magnetite (by weight percentage)

[0018]

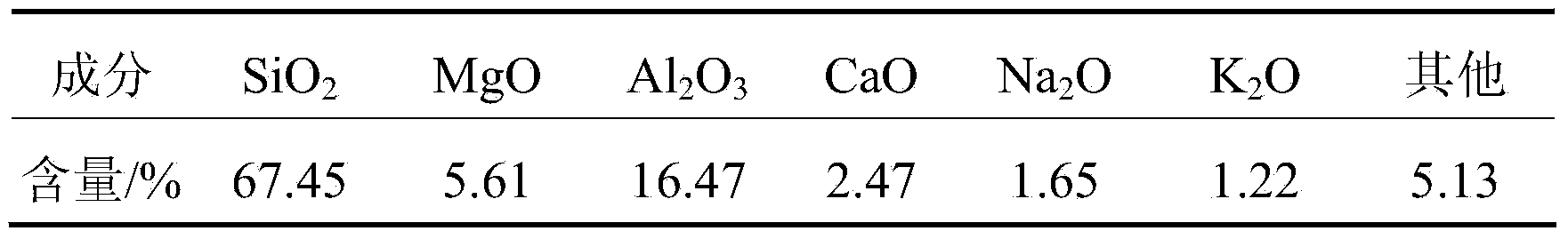

[0019] Table 2 Experimental bentonite chemical composition (by weight percentage)

[0020]

[0021] The implementation steps are as follows:

[0022] (1) Use a ball mill to wet-grind the high-chromium vanadium-titanium magnetite. The fine grinding time is 15 minutes, and the volume fraction of the ore powder particle size is not more than 0.074mm is 100%, and the finely ground vanadium-titanium magnetite concentrate powder is obtained.

[0023] (2) After mixing 100% finely ground vanadium-titanium magnetite concentrate powder, binder bentonite and water in an appropriate proportion, after stewing, a high-chromium vanadium-titanium magnetite with a diameter of 10.0-11.0mmd is ...

Embodiment 2

[0028] Still take the high-chromium type vanadium-titanium magnetite and bentonite in the implementation case 1 as raw materials.

[0029] The implementation steps are as follows:

[0030] (1) Use a ball mill to wet-grind the high-chromium vanadium-titanium magnetite. The fine grinding time is 15 minutes, and the volume fraction of mineral powder with a particle size not greater than 0.074mm is 100%;

[0031] (2) Mix 100% finely ground vanadium-titanium magnetite concentrate powder, binder bentonite and water in an appropriate proportion, and then prepare high-chromium vanadium-titanium magnetite oxide balls with a particle size of 11.5 mm after stewing balls, then dried;

[0032] (3) Put the dried high-chromium-type vanadium-titanium magnetite pellets into a high-temperature furnace at a furnace temperature of 300°C, and ventilate with air. Raise to 900°C at 10°C / min, then rise to 1250°C at 5°C / min, keep at this temperature for 25 minutes, take out the pellets and cool;

...

Embodiment 3

[0036] Still take the high-chromium type vanadium-titanium magnetite and bentonite in the implementation case 1 as raw materials.

[0037] The implementation steps are as follows:

[0038] (1) Use a ball mill to wet-grind the high-chromium vanadium-titanium magnetite. The fine grinding time is 15 minutes, and the volume fraction of the ore powder particle size not greater than 0.074mm is 100%;

[0039](2) After uniformly mixing 100% finely ground vanadium-titanium magnetite concentrate powder, bentonite and water in an appropriate proportion, after stewing, prepare high-chromium vanadium-titanium magnetite oxide pellets with a particle size of 12mm. then dry;

[0040] (3) Oxidation roasting. Put the dried high-chromium-type vanadium-titanium magnetite pellets into a high-temperature furnace at a temperature of 300°C, and ventilate the air, and raise it to 900°C at a rate of 10°C / min, and then rise to a roasting temperature of 1250°C at a rate of 5°C / min. ℃, after keeping a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com