Hypoeutectic high-chromium white cast iron and preparation method thereof

A high-chromium white cast iron and hypoeutectic technology, applied in the field of high-chromium white cast iron, can solve the problems of broken, worn, low impact toughness, etc., and achieve improved hardenability, good casting formability, and crystal nuclei The effect of number increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

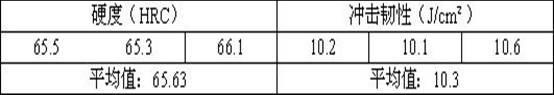

Embodiment 1

[0047] 1, according to principle of the present invention and technical scheme, determine its chemical composition as following table:

[0048] Chemical composition of hypoeutectic high chromium white cast iron (Wt%)

[0049] C Si mn P S Cr V 2.20 0.73 0.6 0.025 0.021 19 0.15 Mo Ni RE Cu Zn Fe 1.2 0.62 0.005 0.6 0.052 margin

[0050] 2. According to the above table, and the components of steel scrap, pig iron, high-carbon ferrochrome, ferromanganese, nickel, molybdenum (selected according to the size of the casting), vanadium, rare earth, and zinc ingot, determine their proportioning relationship and provide the total weight For 100Kg of ingredients.

[0051] 3. Mix scrap steel and pig iron, heat and melt in an intermediate frequency induction furnace, and after the molten iron is melted, add high-carbon ferrochrome, ferromanganese, nickel, and molybdenum in sequence, and then further melt; then, zinc and Rare ear...

Embodiment 2

[0058] 1, according to principle of the present invention and technical scheme, determine its chemical composition as following table:

[0059] Chemical composition of hypoeutectic high chromium white cast iron (Wt%)

[0060] C Si mn P S Cr V 2.36 0.8 0.65 0.026 0.02 21.6 0.25 Mo Ni RE Cu Zn Fe 1.6 0.8 0.005 0.9 0.15 margin

[0061] 2. According to the above table, and the components of steel scrap, pig iron, high-carbon ferrochrome, ferromanganese, nickel, molybdenum (selected according to the size of the casting), vanadium, rare earth, and zinc ingot, determine their proportioning relationship and provide the total weight It is the batching of 250Kg.

[0062] 3. Mix ordinary steel scrap and pig iron, heat and melt in an intermediate frequency induction furnace, and after the molten iron is melted, add high-carbon ferrochrome, ferromanganese, nickel, and molybdenum in turn, and then further melt; then, zinc with ...

Embodiment 3

[0069] 1, according to principle and technical scheme of the present invention, determine its chemical composition as shown in table five.

[0070] Chemical composition of hypoeutectic high chromium white cast iron (Wt%)

[0071] C Si mn P S Cr V 1.9 0.55 0.6 0.028 0.022 14.26 0.12 Mo Ni RE Cu Zn Fe 1.5 0.9 0.006 0.9 0.09 margin

[0072] 2. According to the above table and the composition of steel scrap, pig iron, high-carbon ferrochromium, ferromanganese, nickel, molybdenum, vanadium, rare earth and zinc ingot, determine their proportioning relationship, and provide ingredients with a total weight of 250Kg.

[0073] 3. Mix ordinary steel scrap and pig iron, heat and melt in an intermediate frequency induction furnace, and after the molten iron is melted, add high-carbon ferrochrome, ferromanganese, nickel, and molybdenum in turn, and then further melt; then, zinc with a particle size of less than 10mm Put the rare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com