Blast furnace smelting cost calculating and optimizing method

A technology of cost calculation and optimization method, applied in blast furnace, calculation, blast furnace details, etc., to achieve the effect of reducing smelting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the implementation process and embodiments of the present invention will be described in detail with reference to the accompanying drawings.

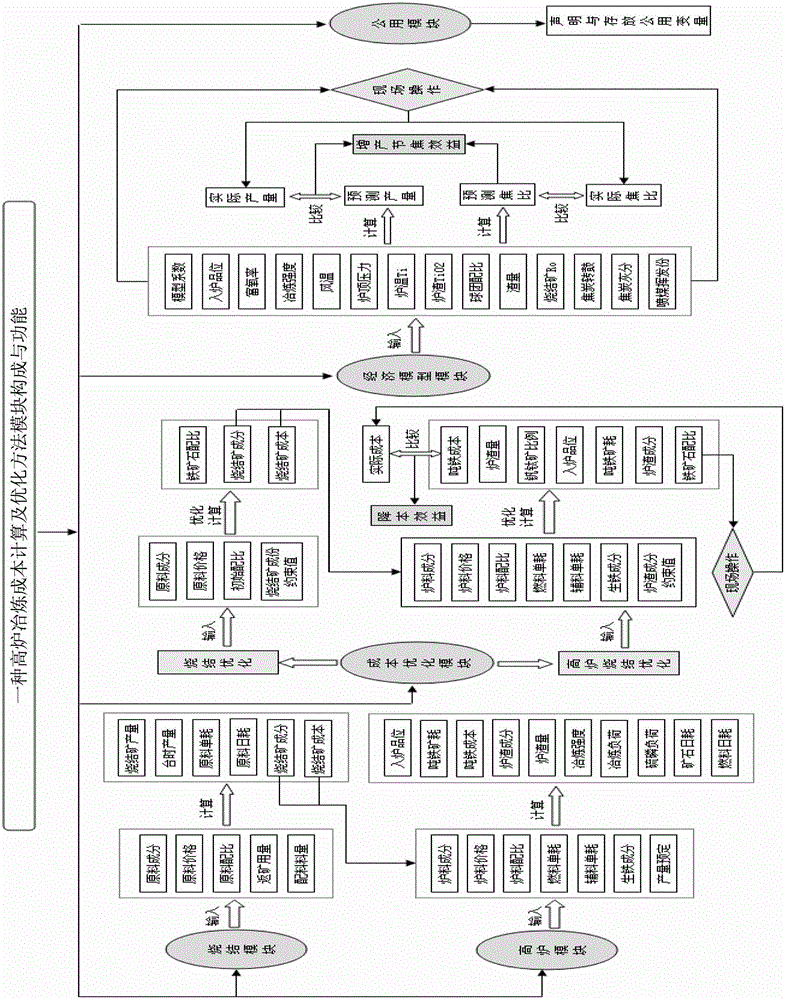

[0036] The blast furnace smelting cost calculation and optimization system of the present invention includes a sintering module, a blast furnace module, a cost optimization module and a production-coke ratio regression module.

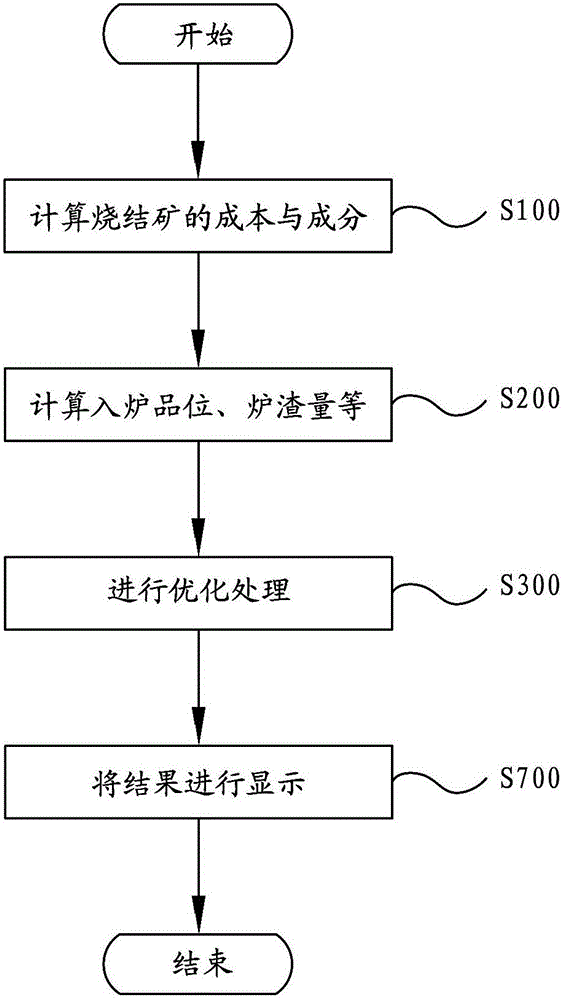

[0037] First, the calculation and optimization method of blast furnace smelting cost corresponding to this system is explained.

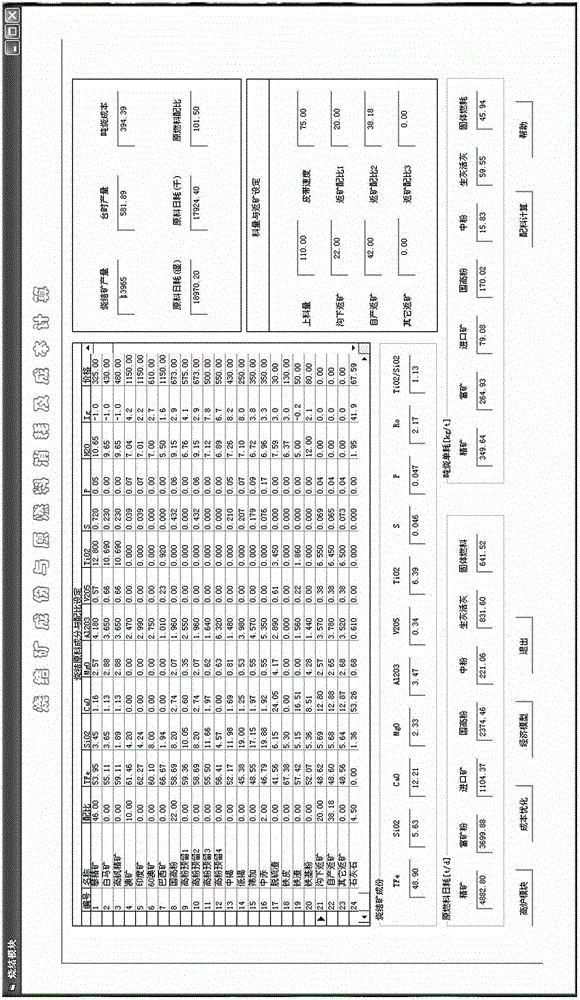

[0038] figure 1 It is a schematic diagram showing the calculation input and output flow and module functions of the present invention. figure 2 It is a flow chart showing the blast furnace smelting cost calculation and optimization method of the present invention. image 3 It is a schematic interface diagram showing the sintering calculation and results of the present invention. Figure 4 It is a schematic interface diagram showing the blast furnace calculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com