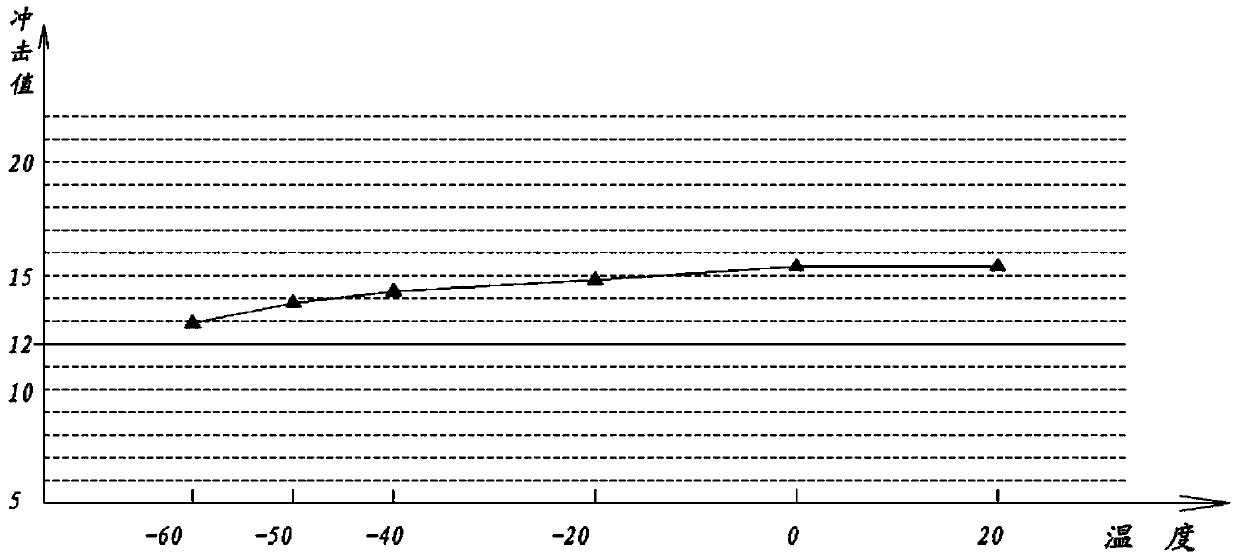

Low-temperature tough ferrite nodular cast iron of 60 DEG C below zero and preparation method thereof

A technology of ductile iron and low temperature toughness, which is applied in the field of ferritic ductile iron, can solve problems such as the inability to maintain good toughness, and achieve the effect of expanding the low temperature toughness area and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

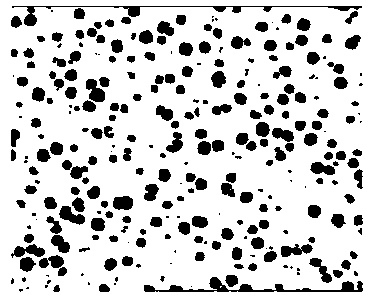

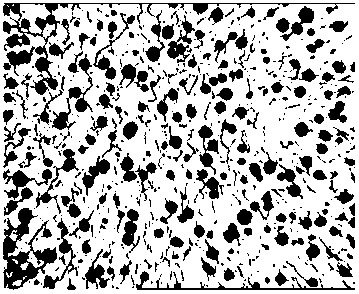

Image

Examples

Embodiment

[0044] The composition and content (wt.%, the balance is Fe) of the present invention's -60°C low-temperature ductile ferritic nodular cast iron are shown in the following table:

[0045]

[0046] The preparation method adopted is:

[0047] The above-mentioned preparation method of low-temperature toughness ferritic nodular cast iron at -60°C, the steps are as follows:

[0048] (1) Ingredients: pig iron, steel scrap, recycled materials and pure nickel;

[0049] The pig iron is high-purity pig iron, the composition of which is C3.8-4.1%, Si≤0.7%, Mn≤0.03%, P≤0.02%, S≤0.01%, Ti≤0.025%, Cr≤0.02%, Sn≈ 0.005%, Sb≈0.0001%, Al≈0.005, and the balance is iron; the composition of scrap steel is: C≤0.1%, Si≤0.1%, Mn≤0.2%, P≤0.01%, S≤0.01%, Ti ≤0.01%, Cr≤0.02%, Sn≈0.0004%, Al≈0.03%, and the balance is iron.

[0050] According to the elemental composition and content of the nodular cast iron to be produced and the elemental composition and content of the raw materials, the batching i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com