Method for preparing hypereutectic high chromium white cast iron

A high-chromium white cast iron and hypereutectic technology, which is applied in the direction of metal processing equipment and process efficiency improvement, can solve the problems of low yield, easy cold separation and shrinkage of castings, and achieves low cost and toughness of castings. Enhanced, tissue-dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Hypereutectic high-chromium white cast iron uses steel scrap, pig iron, high-carbon ferrochromium, ferromanganese, and ferrosilicon as raw materials for smelting. The chemical composition (weight percentage): 4.5%C, 15%Cr, 0.5%Mn , 0.5% Si, 0.05% P, 0.04% S, and the rest is Fe to determine the proportioning relationship of raw materials and carry out batching.

[0031] (2) Mix scrap steel and pig iron first, and melt them in an acidic medium-frequency induction furnace. After the molten iron is melted, add ferromanganese and ferrosilicon in sequence, and then add high-carbon ferrochrome until the temperature reaches 1450°C; After the melt is cleared and deoxidized by aluminum wire, the casting solution is left to stand for 2 minutes. After the slag is removed on the surface of the casting solution, the casting solution is quickly taken out of the furnace and poured into a ladle for slag removal.

[0032] (3) When the temperature of the casting solution is 1300°C, po...

Embodiment 2

[0038] Most of the steps of this embodiment are the same as in Example 1, the differences are as follows:

[0039] (1) The chemical composition (percentage by weight) is: 3.0%C, 35%Cr, 1.5%Mn, 1.5%Si, 0.02%P, 0.04%S, and the rest is Fe.

[0040] (3) When the temperature of the casting solution is 1350°C, pour the casting solution into an ordinary sand mold for casting.

[0041] (4) After cleaning the surface of the casting, put it into an electric furnace and slowly raise the temperature (200°C / hour) to 1000°C.

[0042] (5) Piercing treatment 5 times, the deformation rate is 10s -1 , deformation ratio 0.5.

[0043] (6) Finally, perform tempering treatment (holding temperature: 350°C).

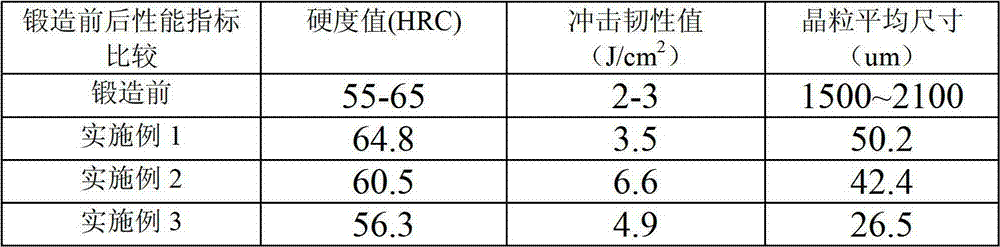

[0044] Through testing, the microstructure and properties of hypereutectic high chromium cast iron obtained in this example are shown in Table 1:

Embodiment 3

[0046] Most of the steps of this embodiment are the same as in Example 1, the differences are as follows:

[0047] (1) The chemical composition (percentage by weight) is: 4.0%C, 25%Cr, 1.0%Mn, 1.0%Si, 0.03%P, 0.03%S, and the rest is Fe.

[0048] (3) When the temperature of the casting solution is 1350°C, pour the casting solution into an ordinary sand mold for casting.

[0049] (4) After cleaning the surface of the casting, put it into an electric furnace and slowly raise the temperature (100°C / hour) to 900°C.

[0050] (5) Piercing treatment 3 times, the deformation rate is 4.5s -1 , deformation ratio 0.1.

[0051] (6) Finally, perform tempering treatment (holding temperature: 350°C).

[0052] Through testing, the microstructure and properties of hypereutectic high chromium cast iron obtained in this example are shown in Table 1:

[0053] Table 1

[0054]

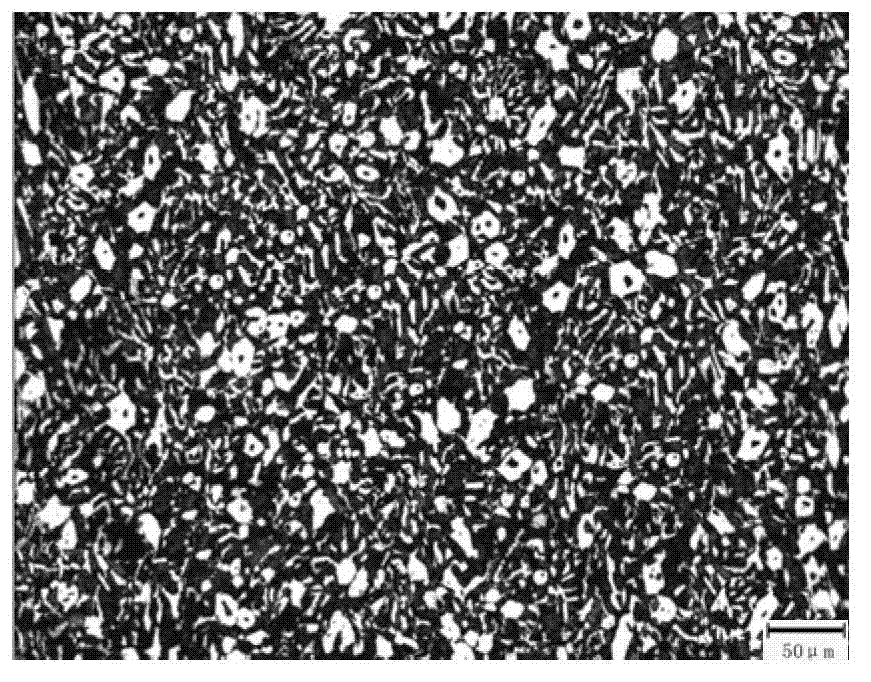

[0055] Depend on figure 1 figure 2 It can be seen from the comparison that the primary carbides are obviously ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com