Harmless regeneration recycling method of trash fly ash by using blast furnace

A technology of garbage fly ash and ironmaking blast furnace, which is applied in the field of garbage fly ash processing, can solve the problems of high construction and operation costs, persistent environmental hazards, genetic defects, etc., and achieve low construction and operation costs, construction and Extreme operating costs, huge social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: mixed injection mode with pulverized coal, the mixed amount of garbage fly ash is 1%-10% of the total weight of injection:

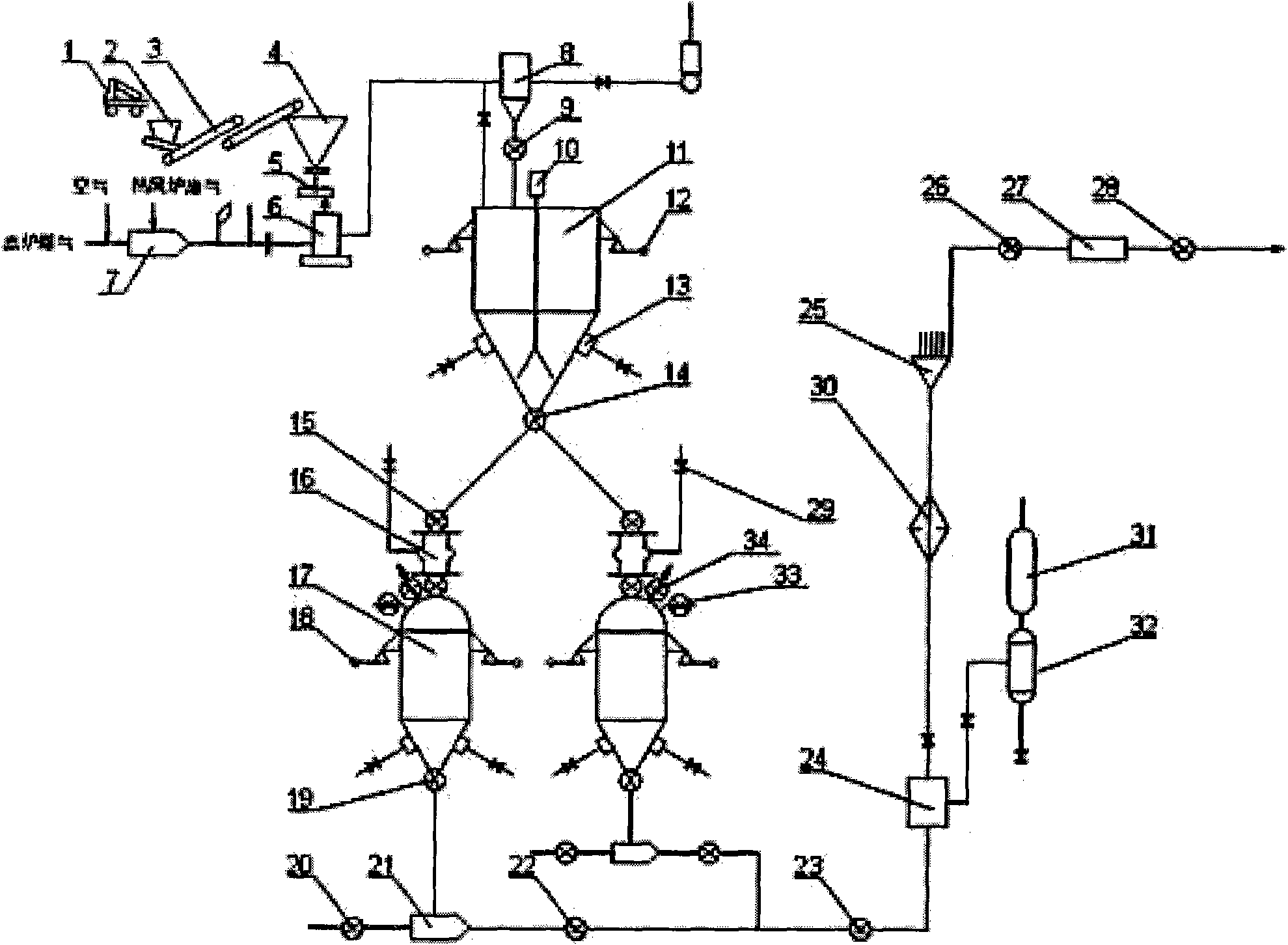

[0027]The blast furnace coal injection process system is mainly composed of raw coal storage and transportation, coal powder preparation, coal powder transportation, coal powder injection, dry gas preparation and gas supply power system. can be used as figure 1 The shown blast furnace pulverized coal injection system (side-by-side tank type), in which 1. Dump truck 2. Media receiving machine 3. Belt conveyor 4. Raw coal bunker 5. Coal feeder 6. Coal mill 7. Drying gas furnace 8. Bag collector 9. Air locker 10. Plug valve 11. Coal powder bin 12. Powder bin electronic scale 13. Fluidizing nozzle 14. Spherical reversing valve 15. Blowing tank feeding valve 16. Soft connection 17. Spray Blowing tank 18. Blowing tank electronic scale 19. Lower coal valve 20. Injection valve 21. Mixer (or adjustable coal powder feeder) 22. Coal powder inj...

Embodiment 2

[0032] 1. The method of making recycled pellets:

[0033] Raw material composition scheme 1 of recycled pellets:

[0034] Steelmaking dedusting sludge containing more than 60% iron accounts for 30%;

[0035] 40% of sintering dust with iron content above 60%;

[0036] 30% of ironmaking gravity dust with iron content above 60%;

[0037] Garbage fly ash accounts for 3%;

[0038] Adhesive GY-31%, heavy metal stabilizer TSA-1 0.2%.

[0039] Raw material composition scheme 2 of recycled pellets:

[0040] Steelmaking dedusting sludge containing more than 60% iron accounts for 50%;

[0041] 30% of sintering dust with iron content above 60%;

[0042] Ironmaking gravity dust with an iron content of more than 60% accounts for 20%;

[0043] Garbage fly ash accounts for 10%;

[0044] Adhesive GY-32%, heavy metal stabilizer TSA-10.4%.

[0045] Raw material composition scheme of recycled pellets 3

[0046] Steelmaking dedusting sludge containing more than 60% iron accounts for 50%;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com