Method for producing vermicular cast iron brake drum

A technology of vermicular graphite cast iron and production method, which is applied in the direction of brake parts, etc., can solve the problems of short service life, poor thermal conductivity, low strength, etc., and achieve the effect of long service life, good thermal conductivity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Controlling chemical composition, cooling conditions and pre-furnace treatment technology is the key to producing vermicular graphite iron brake drum.

[0019] By changing the material ratio, and the pre-furnace treatment process, selecting the vermicular agent and inoculant, and timely testing and tracking the product performance, a large number of tests have been carried out, and the following detailed data have been obtained. The measures for graphite cast iron are as follows:

[0020] 1. Selection of raw materials:

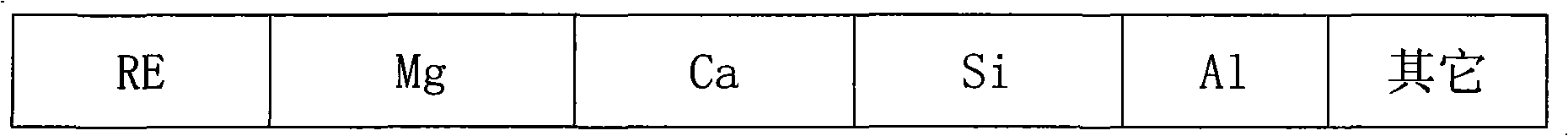

[0021] (1) Pig iron: use Q12 pig iron specified in GB18-82 and GB412-85, the chemical composition is as follows (%):

[0022] C

S

P

Si

mn

4.10~4.30

<0.05

≤0.09

1.00~1.40

≤1.30

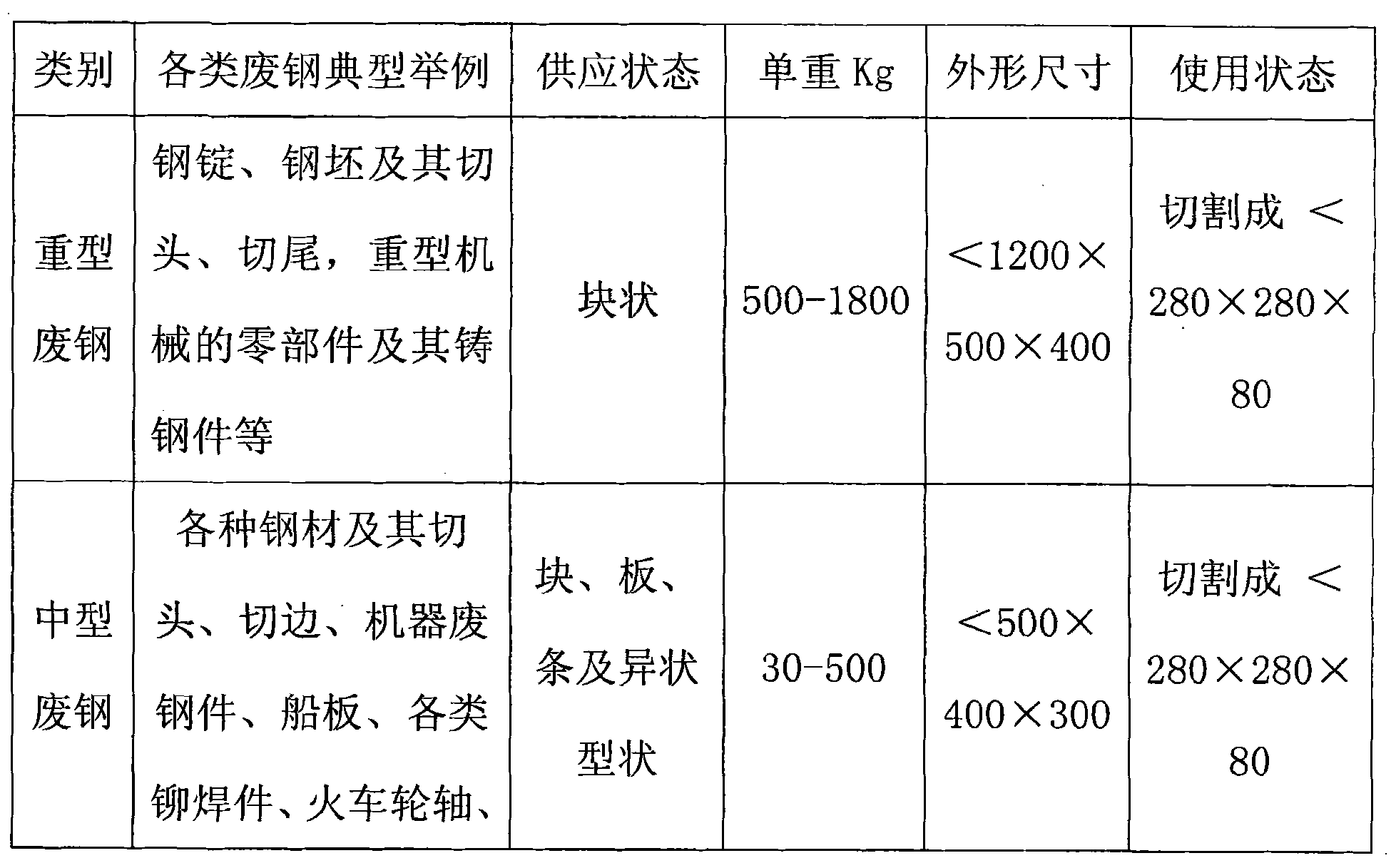

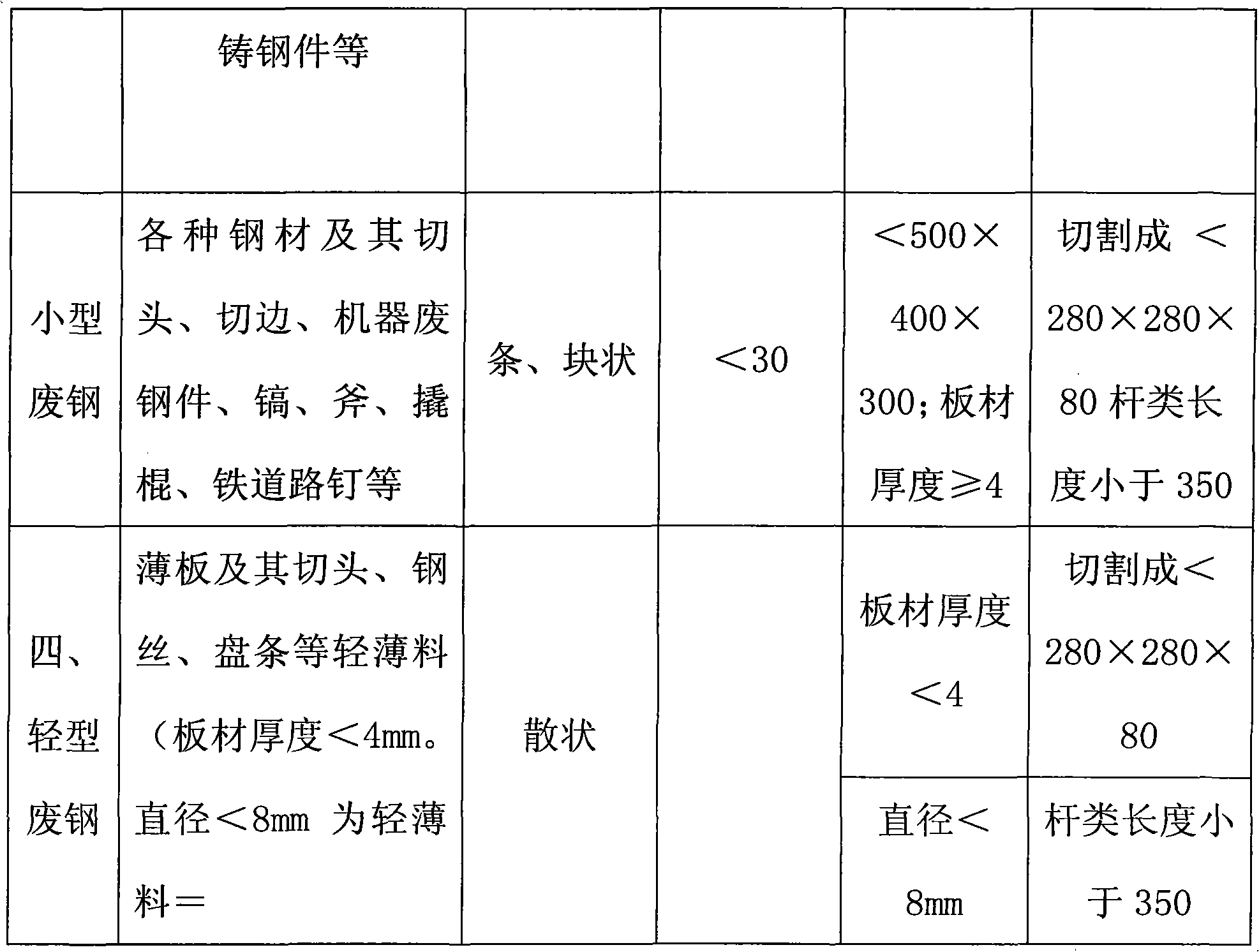

[0023] (2) Steel:

[0024] According to the provisions of GB4223-84 "Classification and Technical Conditions of Returned Carbon Steel Scrap", select carbon steel scrap, including ordinary carbon steel, high-qualit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com