Tobacco shreds drying and moisture moving control method

A shredded tobacco and drying technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of dry shredded tobacco, loss of shredded tobacco aroma, and increase in cigarette manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

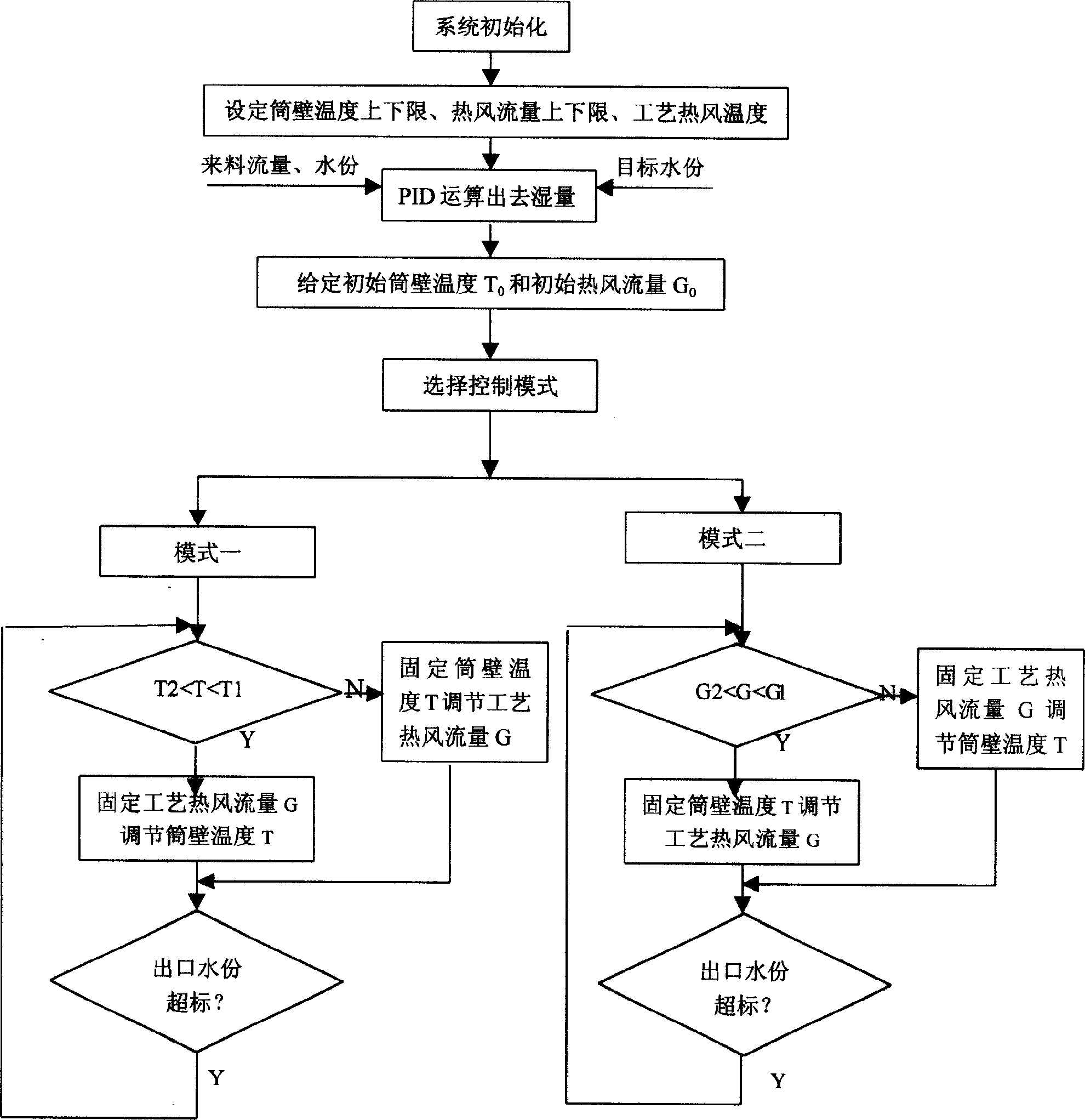

[0011] Embodiment 1: The system uses a Siemens S7-300 programmable controller plus a man-machine interface as a control unit, such as figure 1 As shown, control mode 1 is selected according to the characteristics of the cigarette brand, and the system sets the upper limit T of the tube wall temperature T 1 =170°C, lower limit T 2 =130°C and process hot air temperature and initial process hot air flow G 0 , after the system is initialized, the initial cylinder wall temperature T is given according to the incoming tobacco flow rate, moisture content and target moisture content at the outlet of the drying machine 0 , in the normal silk drying process, when the moisture at the outlet of the silk dryer changes, the temperature of the process hot air and the flow rate of the process hot air remain constant. Constitute a closed-loop control loop to realize the automatic control of the outlet target moisture; and when the incoming tobacco flow and moisture fluctuate greatly, the T ...

Embodiment 2

[0012] Embodiment 2: The system uses a Siemens S7-300 programmable controller plus a man-machine interface as a control unit, such as figure 1 As shown, the second control mode is selected according to the characteristics of the cigarette brand. The system sets the hot air upper limit flow rate G 1 =3000m 3 / h, hot air lower limit flow rate G 2 =1000m 3 / h and hot air temperature and initial cylinder wall temperature T 0 , after the system is initialized, the initial process hot air flow rate G is given according to the incoming tobacco flow rate, moisture content and the target moisture content of the dryer outlet 0 , in the normal silk drying process, when the moisture content at the outlet of the silk dryer changes, the system wall temperature T and the process hot air temperature remain constant, and the frequency of the process hot air fan is automatically adjusted through proportional calculus calculations, thereby adjusting the process hot air flow rate G , constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com