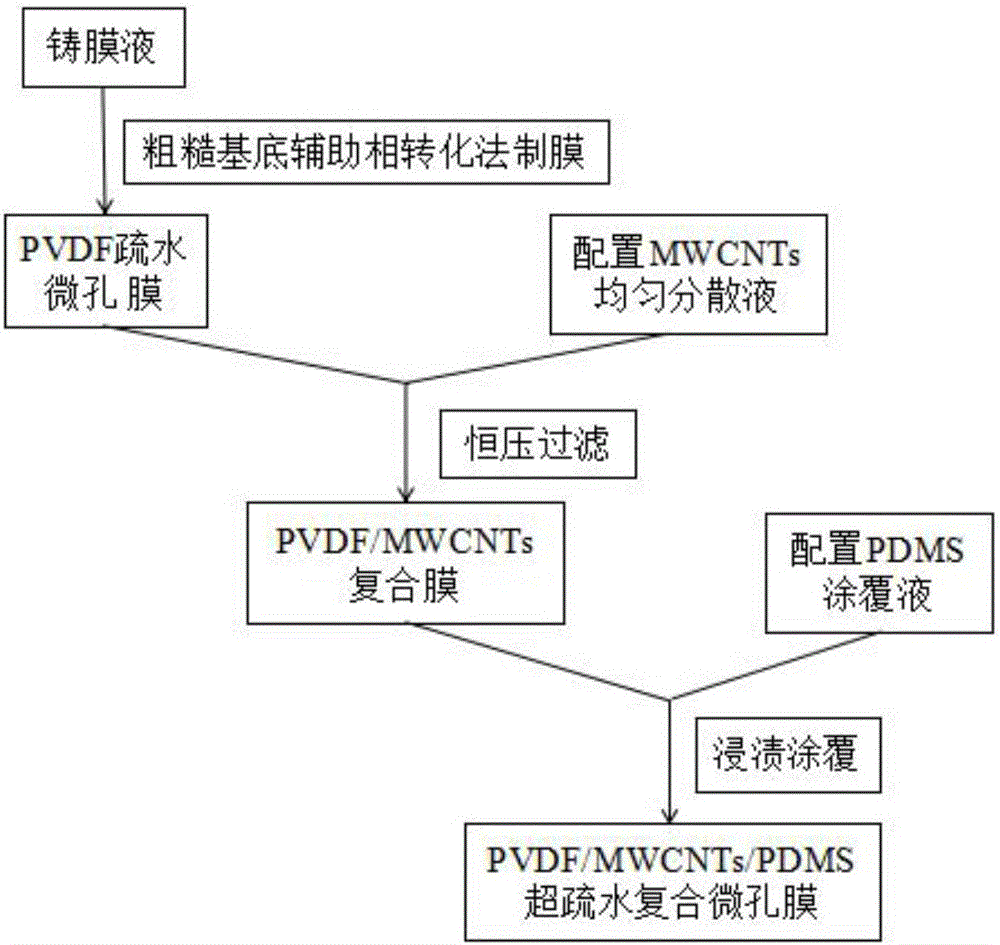

Method for preparing superhydrophobic composite microporous membrane

A microporous membrane and super-hydrophobic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as changing the overall performance of polymers, improve hydrophobic performance, increase contact angle, and reduce freedom. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

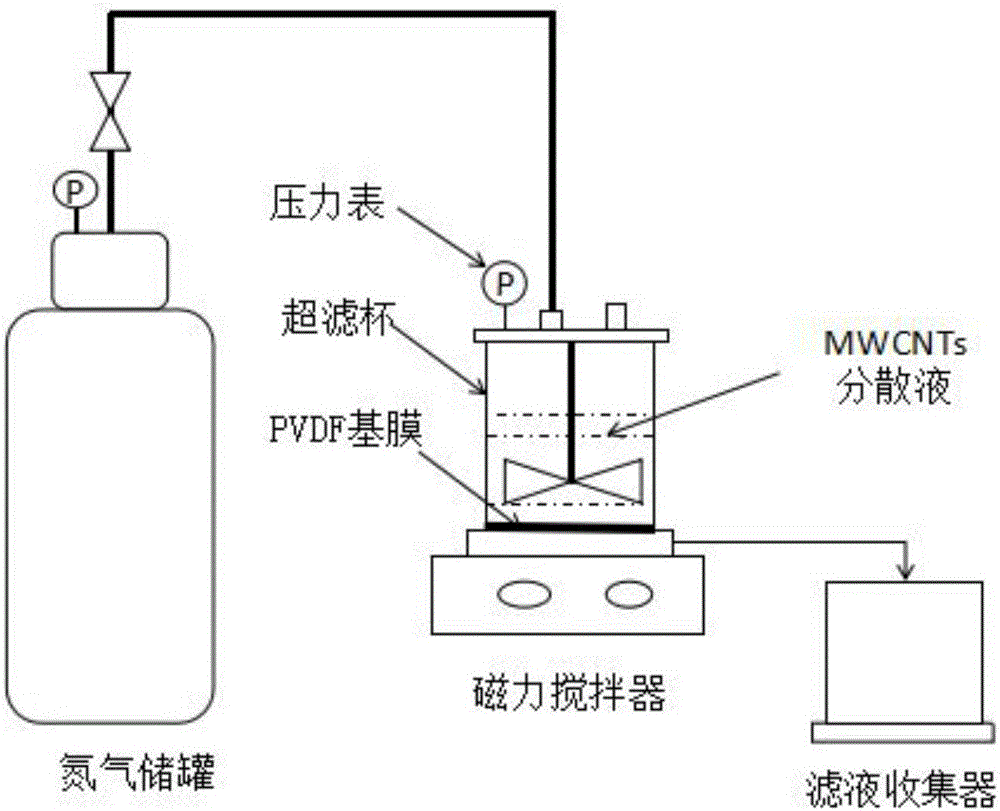

Method used

Image

Examples

Embodiment 1

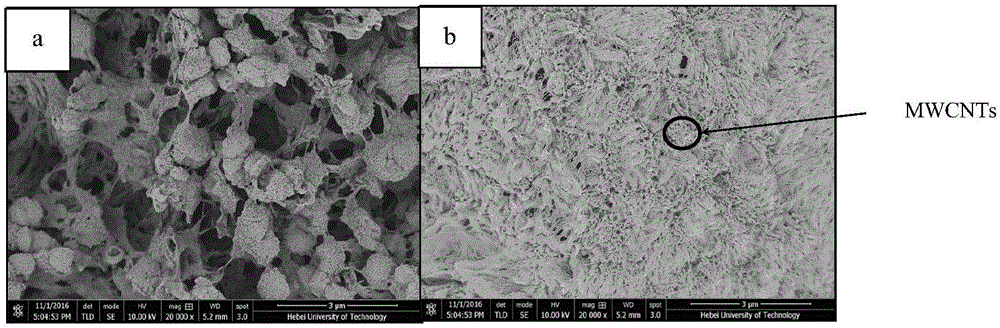

[0023] The configuration quality composition is respectively polyvinylidene fluoride (PVDF)-10%, N,N-dimethylacetamide (DMAc)-84%, n-octanol (1-Octanol)-6% casting solution is placed in 70 In a vacuum drying oven at ℃, the casting solution is completely dissolved and mixed evenly, then the temperature is adjusted to 35 ℃ and left to defoam for 2 days, and the casting solution is evenly scraped on the aluminum alloy plate chemically etched for 8 hours with a scraper. Form a liquid film with a thickness of 0.15 μm-0.2 μm on the plate, place the liquid film in a constant temperature and humidity chamber with a relative humidity of 95% to induce water vapor for 5 minutes, and then immerse the liquid film in a pure water coagulation bath at 35°C for phase separation After 0.5h, the liquid film is solidified into a solid film, removed from the aluminum alloy plate, soaked in deionized water for 2 days, then immersed in ethanol for 1 day, taken out the solid film and dried at room tem...

Embodiment 2

[0029]The configuration quality composition is respectively polyvinylidene fluoride (PVDF)-10%, N,N-dimethylacetamide (DMAc)-84%, n-octanol (1-Octanol)-6% casting solution is placed in 70 In a vacuum drying oven at ℃, the casting solution is completely dissolved and mixed evenly, then the temperature is adjusted to 35 ℃ and left to defoam for 2 days, and the casting solution is evenly scraped on the aluminum alloy plate chemically etched for 8 hours with a scraper. Form a liquid film with a thickness of 0.15 μm-0.2 μm on the plate, place the liquid film in a constant temperature and humidity chamber with a relative humidity of 95% to induce water vapor for 5 minutes, and then immerse the liquid film in a pure water coagulation bath at 35°C for phase separation After 0.5h, the liquid film is solidified into a solid film, removed from the aluminum alloy plate, soaked in deionized water for 2 days, then immersed in ethanol for 1 day, taken out the solid film and dried at room temp...

Embodiment 3

[0034] The configuration quality composition is respectively polyvinylidene fluoride (PVDF)-10%, N,N-dimethylacetamide (DMAc)-84%, n-octanol (1-Octanol)-6% casting solution is placed in 70 In a vacuum drying oven at ℃, the casting solution is completely dissolved and mixed evenly, then the temperature is adjusted to 35 ℃ and left to defoam for 2 days, and the casting solution is evenly scraped on the aluminum alloy plate chemically etched for 8 hours with a scraper. Form a liquid film with a thickness of 0.15 μm-0.2 μm on the plate, place the liquid film in a constant temperature and humidity chamber with a relative humidity of 95% to induce water vapor for 5 minutes, and then immerse the liquid film in a pure water coagulation bath at 35°C for phase separation After 0.5h, the liquid film is solidified into a solid film, removed from the aluminum alloy plate, soaked in deionized water for 2 days, then immersed in ethanol for 1 day, taken out the solid film and dried at room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nitrogen flux | aaaaa | aaaaa |

| Nitrogen flux | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com