Arranging method of single-faced super-hydrophobic cotton fabrics

A cotton fabric, single-sided technology, applied in the field of preparation of single-sided superhydrophobic cotton fabric, can solve the problems of single-sided superhydrophobic finishing, unevenness, high hygroscopicity, etc., and achieve good application prospects, less water, The effect of reducing free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

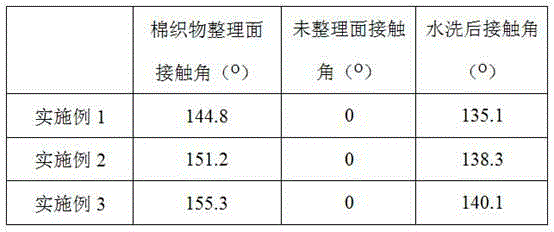

Embodiment 1

[0025] The finishing method of the single-sided superhydrophobic cotton fabric of the present embodiment, the steps are as follows:

[0026] (1) Pre-condition the cotton fabric to control the moisture regain at 8±0.5%;

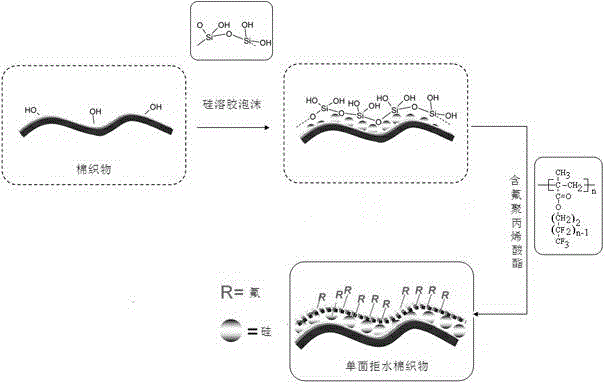

[0027] (2) Evenly mix 3wt% silica sol with pH=4.5, 2g / L sodium alkyl diphenyl ether disulfonate, 1g / L polyacrylamide stabilizer, and tap water, and stir at 3000 rpm at high speed to prepare foamed silicon Sol finishing agent;

[0028] (3) Mix 5wt% water-based fluorocarbon-modified polyacrylic acid, 2g / L ester-containing double root quaternary ammonium salt surfactant, 1g / L polyacrylamide stabilizer, and tap water, and stir at 3000 rpm Preparation of water-based fluorocarbon modified polyacrylic acid finishing agent;

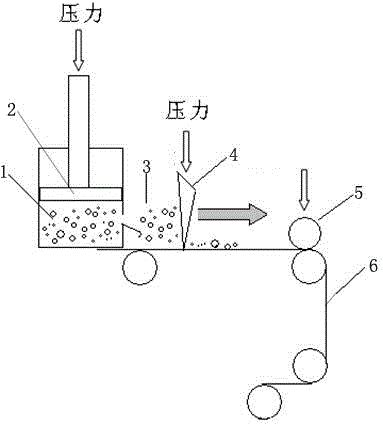

[0029] (4) Fix the cotton fabric 6 on the metal roller collection device 5, inject the prepared silica sol foam finishing agent into the holding container 1, and control the extrusion amount of the foam 3 through the piston rod at the upper end...

Embodiment 2

[0032] The finishing method of the single-sided superhydrophobic cotton fabric of the present embodiment, the steps are as follows:

[0033] (1) Pre-condition the cotton fabric to control the moisture regain at 8±0.5%;

[0034] (2) Mix 3wt% silica sol with pH=3.5, 3g / L Gemini surfactant, 1g / L polyacrylamide stabilizer, and tap water evenly, and stir at 4000 rpm at high speed to prepare foam silica sol finishing agent;

[0035] (3) Mix 8 wt % water-based fluorocarbon modified polyacrylic acid, 3 g / L Gemini surfactant, 1 g / L polytween 80 stabilizer, and tap water, and stir at 4000 rpm to prepare water-based fluorocarbon modified polyacrylic acid. non-toxic polyacrylic acid finishing agent;

[0036] (4) Evenly scrape the prepared foam finishing agent on one side of the pre-conditioned cotton fabric, then steam it at 100°C for 5 minutes, then rinse it for 3 times to neutral, dry and adjust the humidity, and control the moisture regain at 8±0.5 %;

[0037] (5) Apply a water-base...

Embodiment 3

[0039] The finishing method of the single-sided superhydrophobic cotton fabric of the present embodiment, the steps are as follows:

[0040] (1) Pre-condition the cotton fabric to control the moisture regain at 8±0.5%;

[0041] (2) Mix 3wt% silica sol with pH=4, 4g / L Gemini surfactant, 1g / L stabilizer, and tap water evenly, and stir at 5000 rpm at high speed to prepare foamed silica sol finishing agent;

[0042] (3) Mix 10 wt% water-based fluorocarbon-modified polyacrylic acid, 4g / L Gemini surfactant, 1g / L stabilizer, and tap water evenly, and stir at 5000 rpm to prepare water-based fluorocarbon-modified polyacrylic acid finishing agent;

[0043] (4) Evenly scrape the prepared foam finishing agent on one side of the pre-conditioned cotton fabric, then steam it at 100°C for 5 minutes, then rinse it for 3 times to neutral, dry and adjust the humidity, and control the moisture regain at 8±0.5 %;

[0044] (5) Apply a water-based fluorocarbon-modified polyacrylic acid finish evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com