Iron-removing and manganese-removing suspended filter material and preparation method thereof

A technology for suspending filter material and manganese sand, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing operating costs, wasting water resources, and high density of manganese sand, etc. To achieve the effect of reducing equipment cost, reducing equipment pressure and improving backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

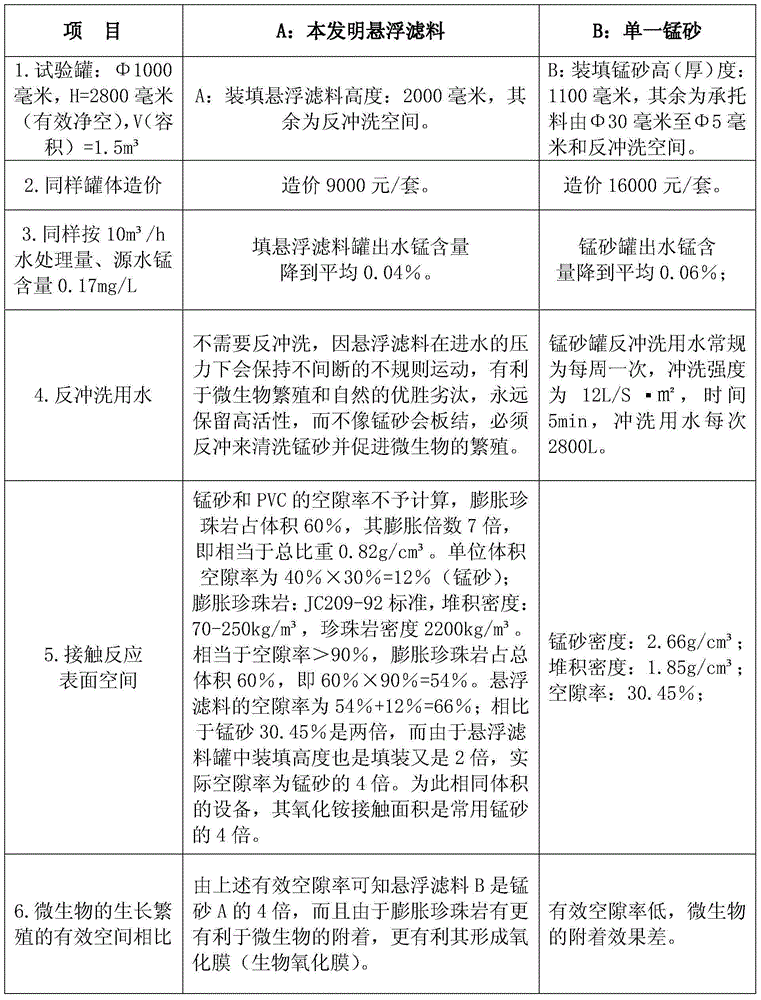

Image

Examples

Embodiment 1

[0024] Example 1 A suspension filter material for removing iron and manganese, which is composed of the following components in parts by weight:

[0025] Manganese sand 650 parts;

[0026] 80 parts of expanded perlite;

[0027] 20 parts of plastic particles.

[0028] The preparation method of the suspension filter material for removing iron and manganese is as follows:

[0029] a. Weigh raw materials

[0030] Weigh 650 grams of manganese sand with a particle size of 1-3mm and a manganese content greater than 40% by weight; ②a particle size of 1-3mm and a specific gravity of less than 200kg / m 3 80 grams of expanded perlite, ③ 20 grams of plastic particles (PE particles) with a melting point of less than 125 ° C and a particle size of 1-3 mm;

[0031] b. smash

[0032] Put the three raw materials into the pulverizer independently and pulverize them fully so that the particle size is 0.5mm;

[0033] c. Mix well

[0034] Feed manganese sand, expanded perlite and crushed pla...

Embodiment 2

[0039] Example 2 A suspension filter material for removing iron and manganese, which is composed of the following components in parts by weight:

[0040] Manganese sand 680 parts;

[0041] 85 parts of expanded perlite;

[0042] 30 parts of plastic particles.

[0043] The preparation method of the suspension filter material for removing iron and manganese is as follows:

[0044] a. Weigh raw materials

[0045] Weigh 680 grams of manganese sand with a particle size of 1-3mm and a manganese content greater than 40% by weight; ②a particle size of 1-3mm and a specific gravity of less than 200kg / m 3 85 grams of expanded perlite, ③ 30 grams of plastic particles (PE particles) with a melting point of less than 125 °C and a particle size of 1-3 mm;

[0046] b. smash

[0047] Put the three raw materials into the pulverizer independently and pulverize them fully so that the particle size is 0.8mm;

[0048] c. Mix well

[0049] Feed manganese sand, expanded perlite and crushed plas...

Embodiment 3

[0054] Example 3 A suspension filter material for removing iron and manganese, which is composed of the following components by weight:

[0055] Manganese sand 700 parts;

[0056] 90 parts of expanded perlite;

[0057] 40 parts of plastic particles.

[0058] The preparation method of the suspension filter material for removing iron and manganese is as follows:

[0059] a. Weigh raw materials

[0060] Weigh 700 grams of manganese sand with a particle size of 3mm and a manganese content greater than 40% by weight, and ②a particle size of 3mm and a specific gravity of less than 200kg / m 3 90 grams of expanded perlite, ③ 40 grams of plastic particles (PE particles) with a melting point of less than 120 ° C and a particle size of 3 mm;

[0061] b. smash

[0062] Put the three raw materials into the pulverizer independently and pulverize them fully so that the particle size is 1mm;

[0063] c. Mix well

[0064] Feed manganese sand, expanded perlite and crushed plastic particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com