Three-layer lithium battery diaphragm and preparation method thereof

A lithium battery separator and separator technology, which is applied in battery pack components, chemical instruments and methods, circuits, etc. Reduced pore temperature, good high temperature stability, stable porosity and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

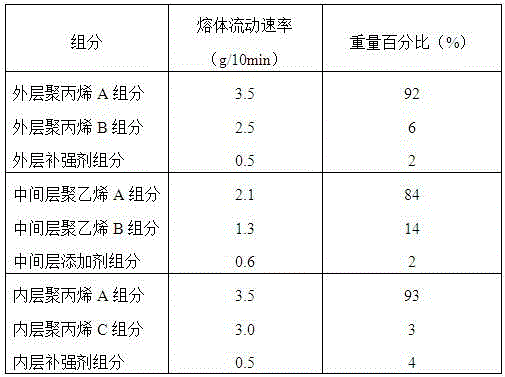

[0040] A three-layer lithium battery separator, prepared by a three-layer co-extrusion process, including an outer layer, a middle layer and an inner layer, the three-layer material composition formula is shown in Table 1, wherein the outer layer is made of 92% polypropylene group A 6% polypropylene B component and 2% reinforcing agent component as raw materials, the middle layer is made of 84% polyethylene A component, 14% polyethylene B component and 2% additive component It is prepared from raw materials, and the inner layer is prepared from 93% polypropylene component A, 3% polypropylene C component and 4% reinforcing agent component.

[0041] Table 1 The melt flow rate and composition ratio of each component of Example 1

[0042]

[0043] The preparation method of the three-layer lithium battery diaphragm is as follows:

[0044] a) Mixing and suction steps: According to the ratio of each component in Table 1, mix the outer layer, middle layer and inner layer through a...

Embodiment 2

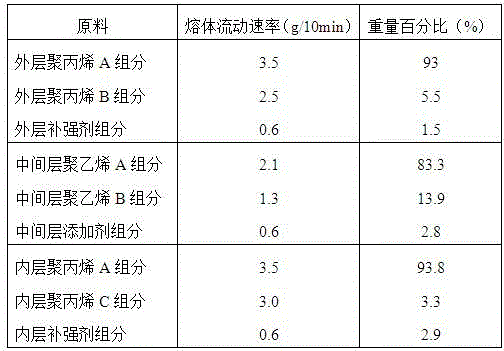

[0049] A three-layer lithium battery separator, prepared by a three-layer co-extrusion process, including an outer layer, a middle layer and an inner layer, the three-layer material composition formula is shown in Table 2, wherein the outer layer is made of 93% polypropylene group A The middle layer is made of 83% polyethylene A component, 14% polyethylene B component and 3% additive component. It is prepared from raw materials, and the inner layer is prepared from 94% polypropylene component A, 3% polypropylene C component and 3% reinforcing agent component.

[0050] Table 2 The melt flow rate and composition ratio of each component of Example 2

[0051]

[0052] The preparation method of the three-layer lithium battery diaphragm is as follows:

[0053] a) Mixing and suction steps: According to the ratio of each component in Table 2, mix the outer layer, middle layer and inner layer through a high-speed mixer for half an hour to mix evenly, and then use a vacuum suction m...

Embodiment 3

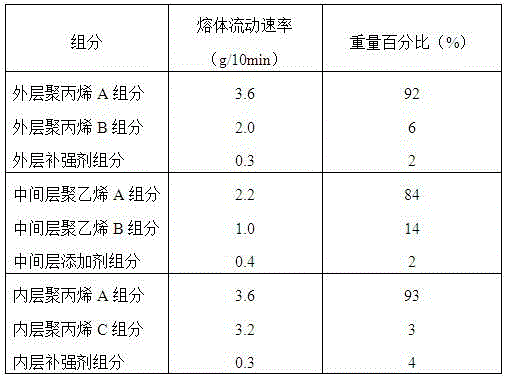

[0058] A three-layer lithium battery separator, prepared by a three-layer co-extrusion process, including an outer layer, a middle layer and an inner layer, the three-layer material composition formula is shown in Table 3, wherein the outer layer is made of 93% polypropylene A group 5.5% polypropylene B component and 1.5% reinforcing agent component as raw materials, the middle layer is made of 83.3% polyethylene A component, 13.9% polyethylene B component and 2.8% additive component It is prepared from raw materials, and the inner layer is prepared from 93.8% polypropylene component A, 3.3% polypropylene C component and 2.9% reinforcing agent component.

[0059] Table 3 The melt flow rate and composition ratio of each component of Example 3

[0060]

[0061] The preparation method of the three-layer lithium battery diaphragm is as follows:

[0062] a) Mixing and suction steps: According to the ratio of each component in Table 3, mix the outer layer, middle layer and inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com