Composite absorption core

A technology of absorbing core and absorbing body, which is applied in the direction of absorbing pad, medical science, etc., can solve the problems such as separation of absorbent material and increase in the distribution of absorbent material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

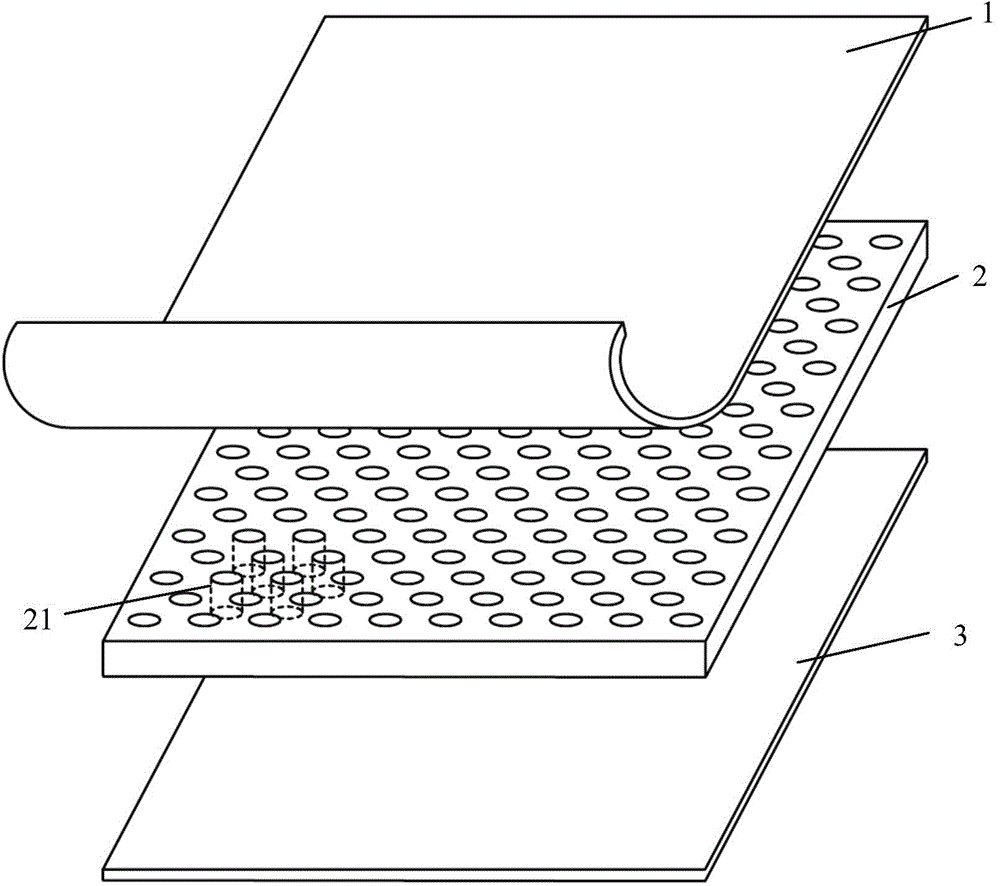

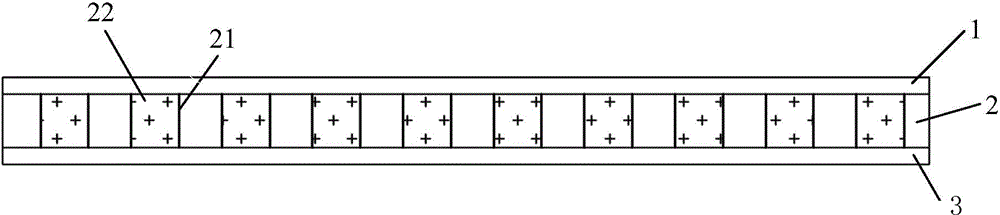

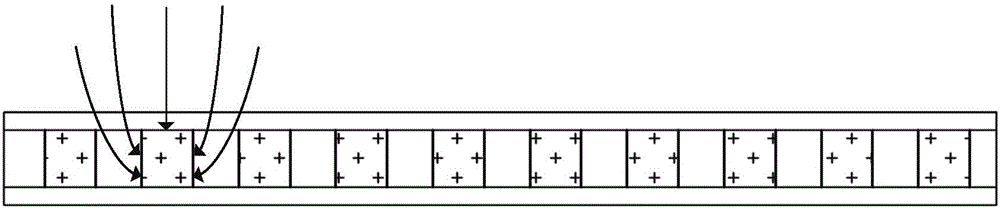

[0017] See figure 1 , figure 1 A schematic structural view of the composite absorbent core of the present invention is shown. Such as figure 1 As shown, the composite absorbent core comprises a topsheet 1 , an intermediate absorbent layer 2 and a backsheet 3 . The middle absorbent layer 2 is sandwiched between the top layer 1 and the bottom layer 3 .

[0018] The surface layer 1 can be made of materials with liquid-permeable function, such as water-permeable dust-free paper or water-permeable non-woven fabric. The bottom layer 3 can be made of liquid-impermeable material, such as water-repellent non-woven fabric. Of course, the bottom layer 3 can also be made of the same or similar material as the surface layer 1 as required.

[0019] The middle absorbent layer 2 can adopt traditional materials, such as fluffy non-woven fabric material, fluffy fiber paper and other materials. The key feature of the present invention is: the middle absorbent layer 2 is provided with longi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com