Manufacturing method of basal body bearing super absorbent resin, water absorption core body and disposable sanitary product

A technology of superabsorbent resin and production method, applied in sanitary napkins, applications, absorbent pads, etc., can solve the problems of insufficient utilization of superabsorbent resin and reduced liquid absorption of disposable sanitary products, etc., to achieve the best comfort and cost performance , improve environmental protection, and change the effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

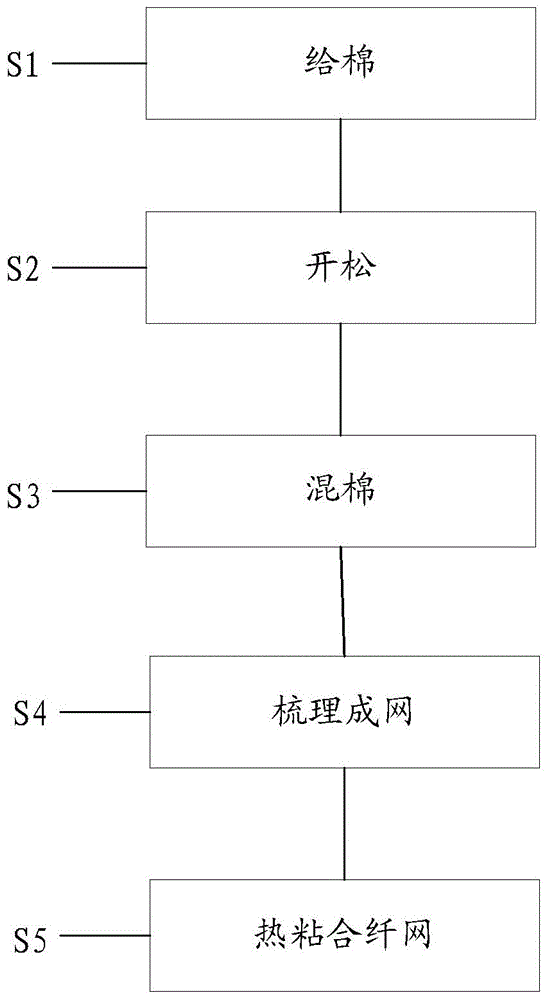

[0026] This example provides a method for manufacturing a matrix carrying a superabsorbent resin, including the following steps, the flow chart of which is as follows: figure 1 shown.

[0027] S1: Feed cotton.

[0028] In this step, polyester low-melting-point staple fibers and polyester staple fibers are respectively supplied, wherein the deniers of the polyester low-melting-point staple fibers are 1D-10D, and the deniers of the polyester staple fibers are 1D-10D, and specific deniers can be selected according to actual applications.

[0029] S2: loosen.

[0030] In this step, the polyester low-melting-point staple fiber and the polyester staple fiber are respectively opened by an opener, and the purpose is to loosen the compacted and entangled polyester low-melting-point staple fiber and the polyester staple fiber respectively.

[0031] S3: Cotton blend.

[0032] Fully mix the polyester low-melting-point staple fiber and polyester staple fiber loosened in step S2, and the...

Embodiment 2

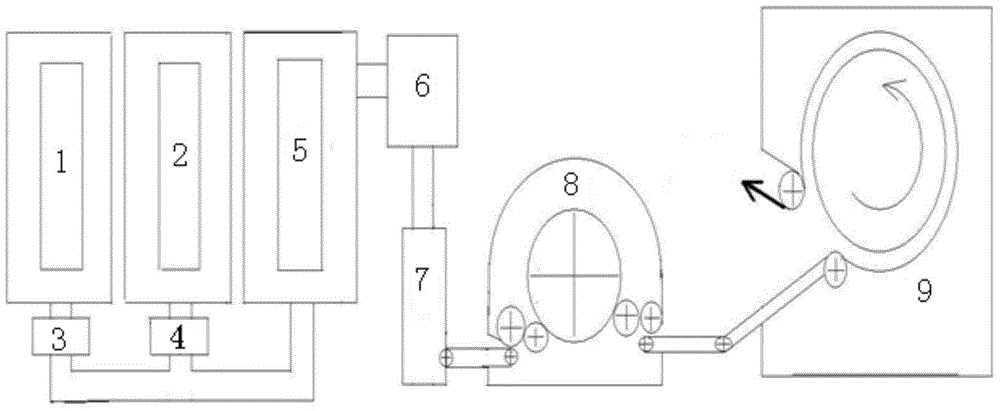

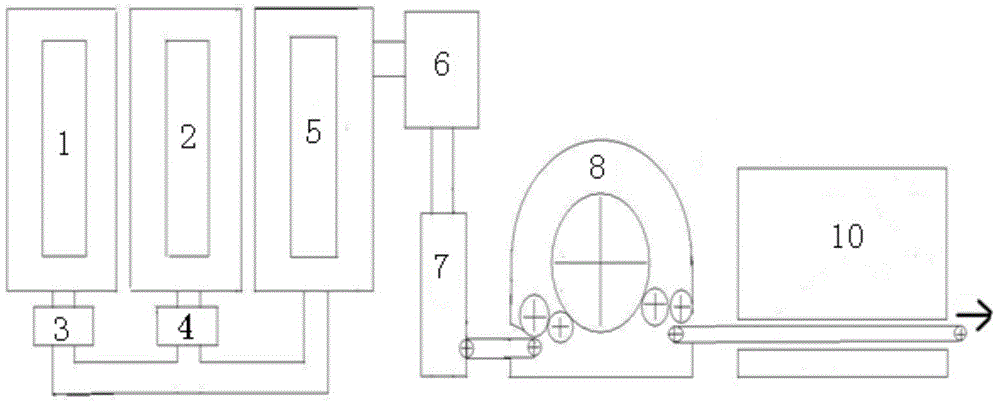

[0040] Such as image 3 As shown, the difference between this example and Example 1 mainly lies in that the hot air process in this example adopts the flat screen hot air production process, and correspondingly, the dryer in this example is a flat screen dryer 10 .

[0041] Concretely, polyester low melting point staple fiber and polyester staple fiber are proportioned according to the ratio of 50%:50%. Two cotton feeders 2; the first cotton feeder 1 feeds the polyester low-melting point staple fibers into the first opener 3, and the first opener 3 opens the polyester low-melting point staple fibers for the purpose of compressing, Intertwined polyester low-melting-point staple fibers are loosened; similarly, the second cotton feeder 2 feeds the polyester staple fibers into the second opener 4, and the second opener 4 opens the polyester staple fibers; The decomposed low-melting point staple fiber and polyester staple fiber are transported to the cotton blender 5 and fully mix...

Embodiment 3

[0043] Based on Embodiment 1 and Embodiment 2, this example provides a water-absorbent core for disposable sanitary products, such as Figure 4 As shown, the water-absorbent core includes a super-absorbent resin 101 and a base 102 , and the base 102 is used to accept the super-absorbent resin 101 .

[0044] The matrix 102 of this example is basically made up of polyester low melting point staple fiber and polyester staple fiber, and polyester low melting point staple fiber and polyester staple fiber are mixed with the ratio of 10%~90%:90%~10%, the ratio of this example is preferably 50%:50%, wherein, the polyester staple fiber is a three-dimensional crimped hollow staple fiber.

[0045]In addition, in this example, the manufacturing method of the base body 102 may adopt the manufacturing method of the first embodiment or the second embodiment. For details, please refer to the first and second embodiments, which will not be repeated in this example.

[0046] Because the matrix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com