Pneumatic emission-type forest extinguishing cannonball

A technology for fire extinguishing shells and forests, which is applied in the field of pneumatically launched forest fire extinguishing shells, which can solve the problems of small canopy fire effect and limit the dispersion range of fire extinguishing agents, and achieve excellent fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

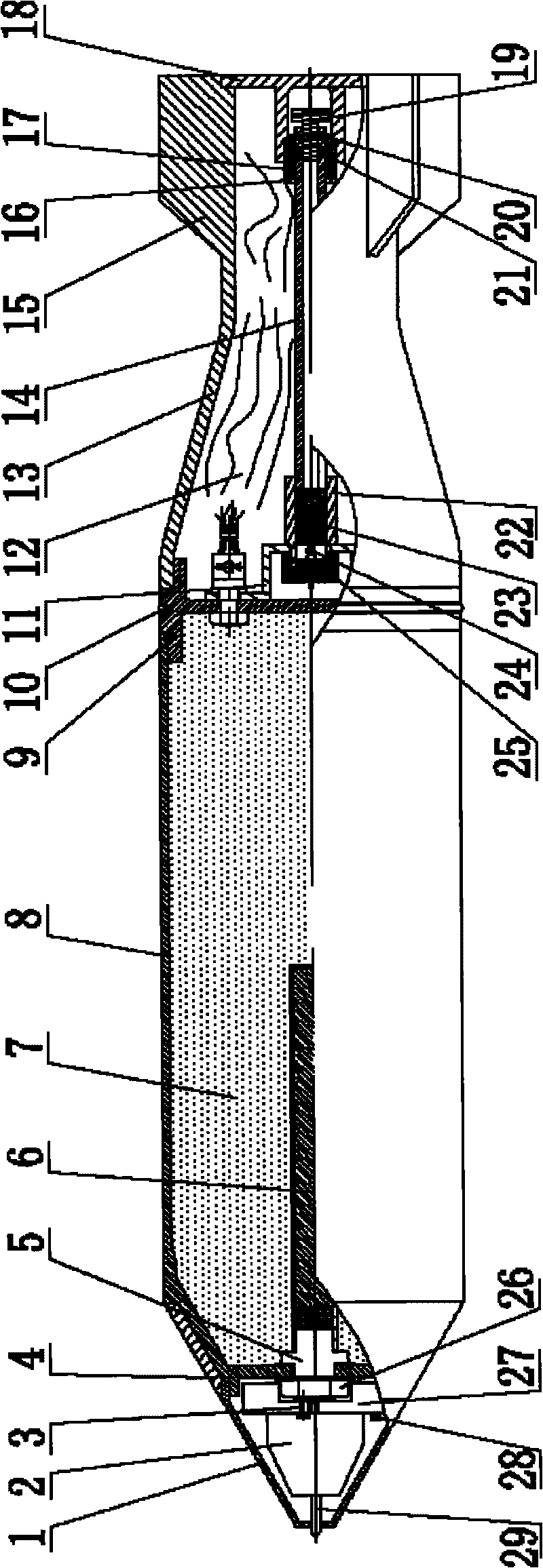

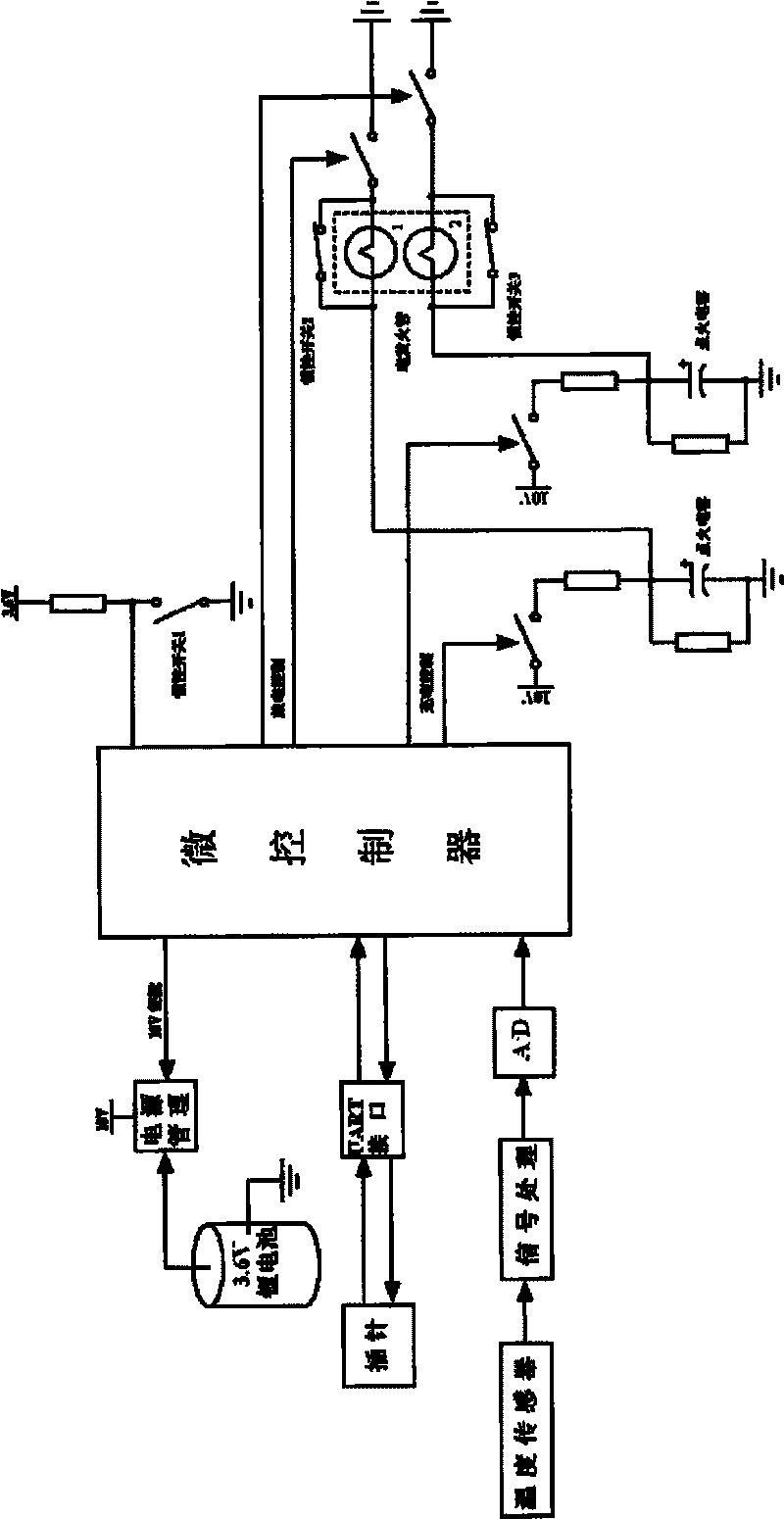

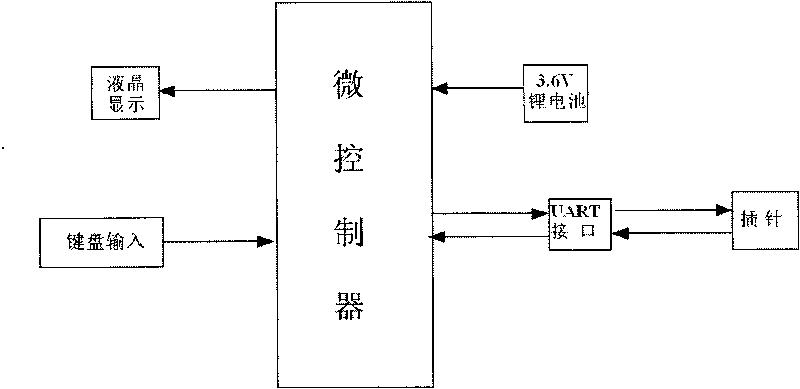

[0019] Combine figure 1 , The composition of the pneumatically launched forest fire extinguishing shell of the present invention includes: hood 1, inertial switch 2, screw 3, cast steel sheet 4, connecting screw 5, central blast tube 6, fire extinguishing agent 7, cylindrical shell 8, connecting plate 9 , Sealing ring 10, bowl cover 11, deceleration umbrella 12, umbrella bin shell 13, center tube 14, tail wing 15, liner ring 16, duct 17, rear cover 18, ram 19, pin 20, ball 21, center The liner 22, the propellant 23, the electric ignition tube 24, the rear screw cap 25, the screw cap 26, the control circuit chip 27, the socket 28 and the temperature sensor 29.

[0020] The hood and the front end of the cylindrical shell are connected by threads. The fuze is fixed on the nut on the front end of the cylindrical shell by screws, and the hood can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com