Firefighting robot and method thereof

A fire-fighting robot and steering gear technology, applied in fire rescue, etc., can solve the problems of high cost, bulkiness, and lack of fire-spraying effect, and achieve the best fire-extinguishing effect, cost reduction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

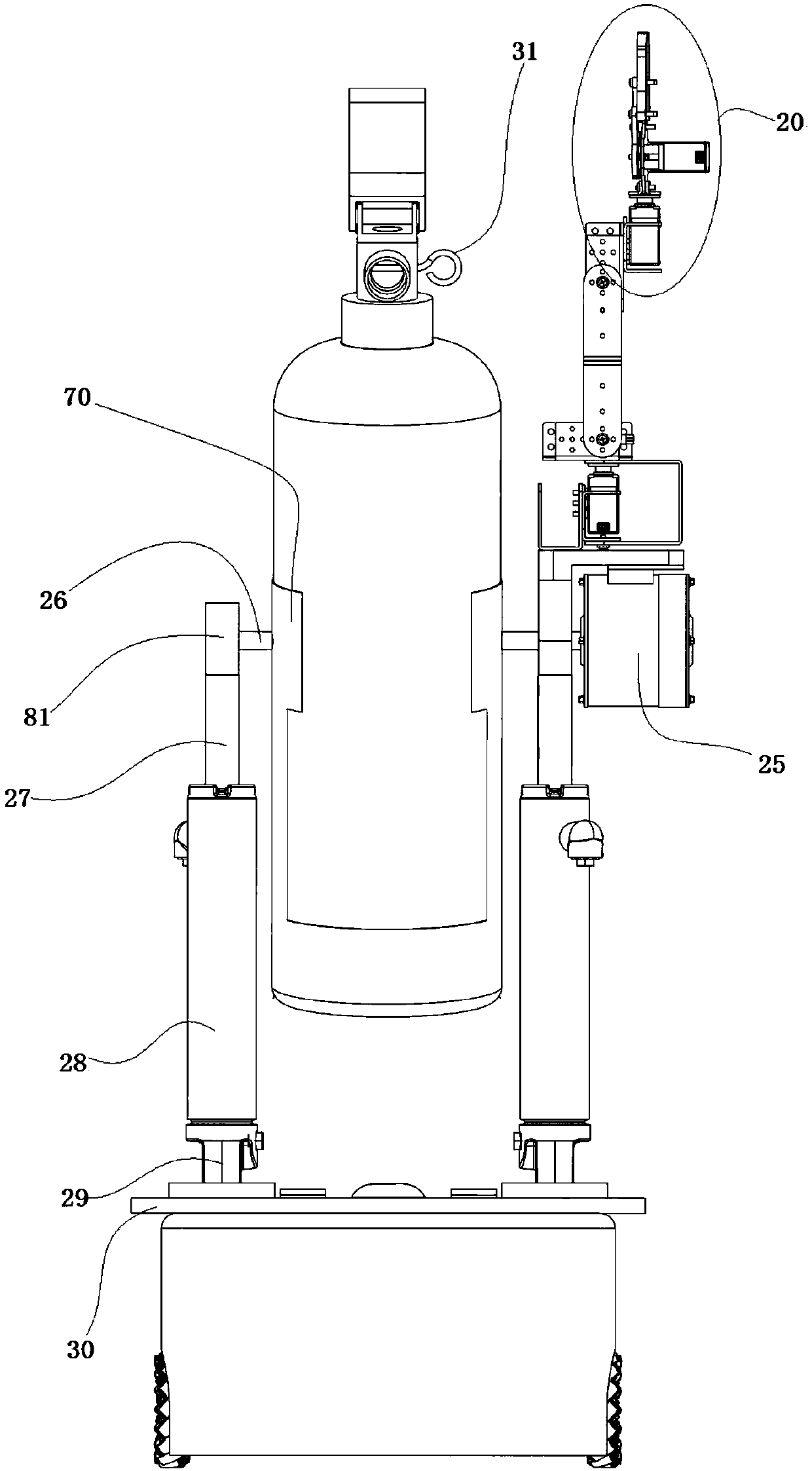

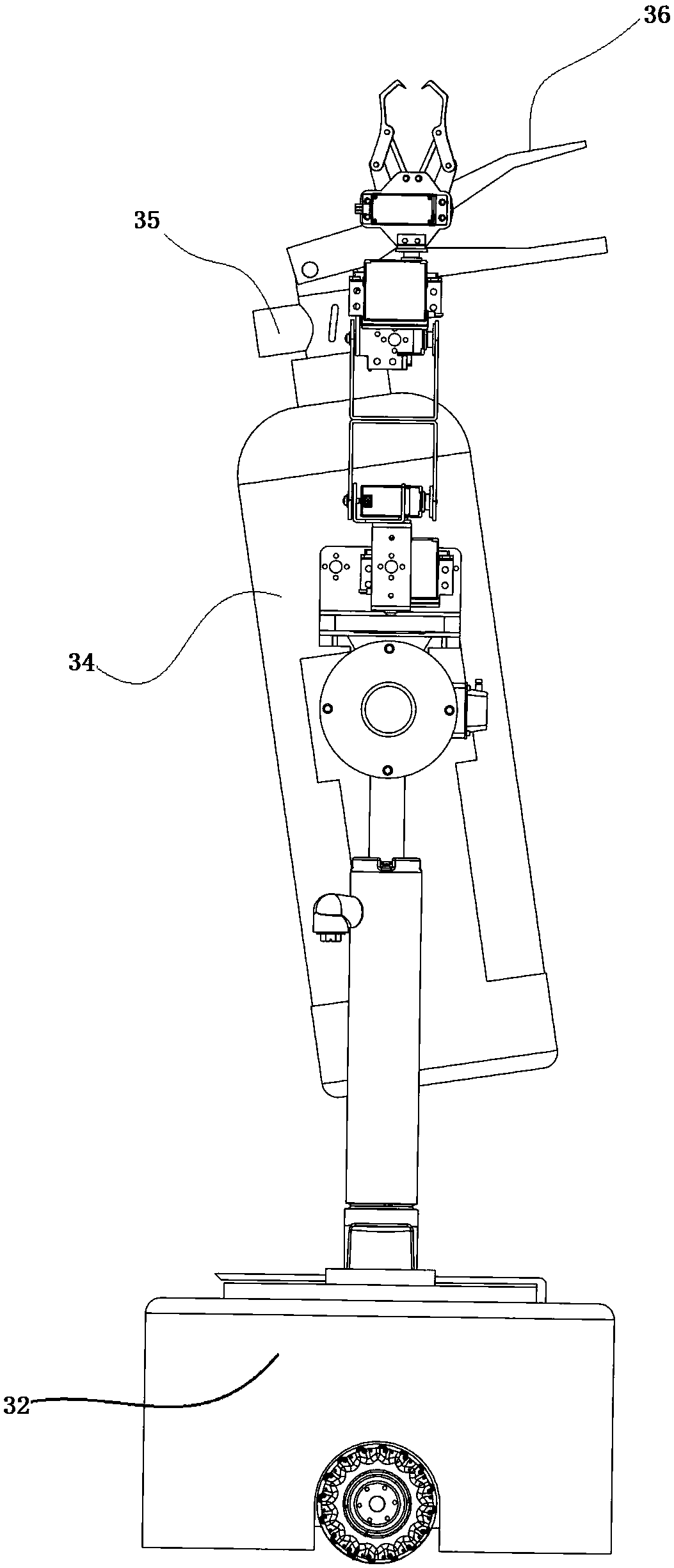

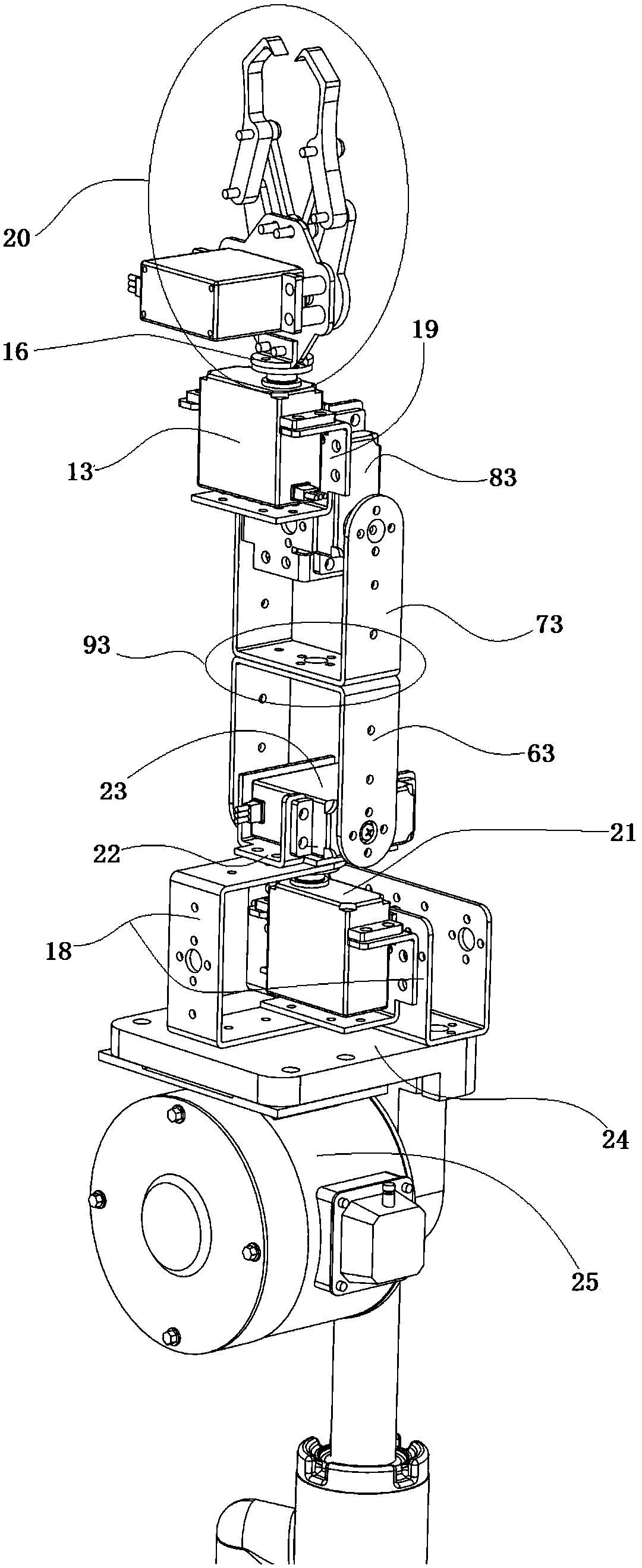

[0031] as attached Figures 1 to 4 A kind of fire-fighting robot shown, comprises walking unit 32, bearing platform 30, hydraulic cylinder seat 29, hydraulic cylinder 28, bottle type fire extinguisher 34, fire extinguisher clamps tow 70, first steering gear 25 and mechanical arm; Described bearing platform 30 Horizontally arranged on the walking unit 32, the two hydraulic cylinder bases 29 are symmetrically arranged on the bearing platform 30, and the two hydraulic cylinders 28 are vertically installed on the two hydraulic cylinder bases 29 respectively; The upper end of the push rod 27 of the hydraulic cylinder 28 is respectively provided with a bearing seat 81; the bottle body of the bottle fire extinguisher 34 can be detachably placed in the draw-in slot of the fire extinguisher clip 70, and only needs to be replaced with a new bottle fire extinguisher after use. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com