Processing method capable of reserving all components of dendrobium officinale

A technology of dendrobium candidum and processing method, which is applied in the direction of medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, pharmaceutical formulas, etc., can solve the problem of reducing the content of active ingredients in dendrobium candidum, which is not conducive to the preservation of fresh products and Reprocessing, storage temperature and humidity requirements are high, so as to improve the utilization rate of medicinal materials, easy storage and reprocessing, and enhance the edible and medicinal value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

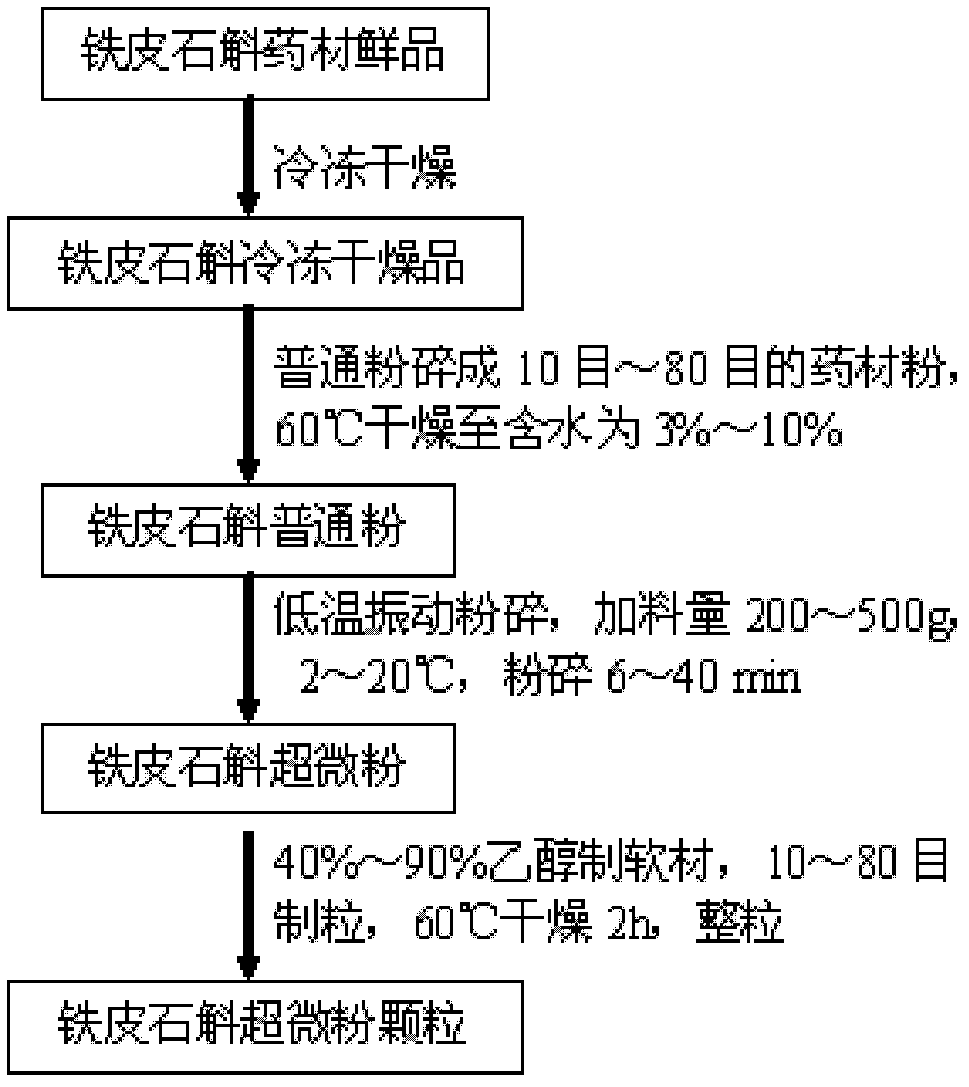

[0023] An example of the processing method of Dendrobium candidum with all components preserved: (please give a specific example to illustrate the production process, and the parameters should use the values during actual operation)

[0024] Take fresh Dendrobium officinale to remove fibrous roots and impurities, wash it, wipe off the film on the epidermis, cut it into 3cm pieces, weigh 1000g, put it in a quick freezer for 4 hours, and lower the temperature to -80°C to freeze it all. The temperature of the cold trap drops to -40°C and starts vacuuming. When the vacuum degree drops to 25Pa, the temperature of Dendrobium officinale is lower than -40°C during the sublimation process, and the sublimation is dried for 38 hours. When the vacuum pressure drops to 10Pa, the sublimation is dried. The process is over; continue to set the plate temperature to 25°C, vacuumize, and analyze for 12 hours. The freeze-dried medicinal materials are generally crushed through a 20-mesh sieve,...

Embodiment 2

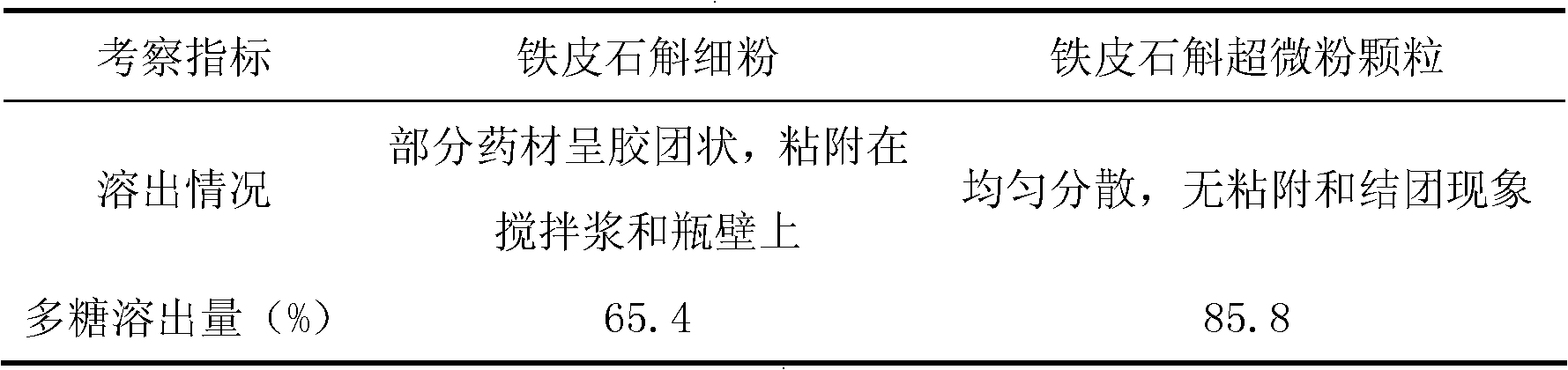

[0028] Main component polysaccharide content and in vitro dissolution test in Dendrobium officinale granules prepared by the method of Example 1

[0029] 2.1 Comparison of polysaccharide content between fresh Dendrobium officinale and ultrafine powder

[0030] Take by weighing two portions of Dendrobium candidum fresh product, each portion 600g. One part is cut into 2-3 cm sections, and the dried product is vacuum freeze-dried according to the above-mentioned process, pulverized by an ordinary pulverizer to obtain a medicinal material powder between 10-80 meshes, and dried at 60° C. under normal pressure until the water content is 3%-10%. Crush with a low-temperature vibrating pulverizer, feed 200-500g, 2-20°C, crush for 6-40 minutes, use 40%-90% ethanol as a soft material, granulate through a 10-80 mesh sieve, and dry at 60°C After 2 hours, the grains were granulated to obtain the superfine powder particles of Dendrobium candidum. The other portion was cut into 1cm sections...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com