Medical composite antimicrobial tube and preparation method thereof

A technology of compounding antibacterial and silver powder, applied in the field of medical compound antibacterial tube and its preparation, can solve the problems of easy cracking, decreased rigidity, easy rupture, etc., and achieves the effect of good antibacterial effect and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

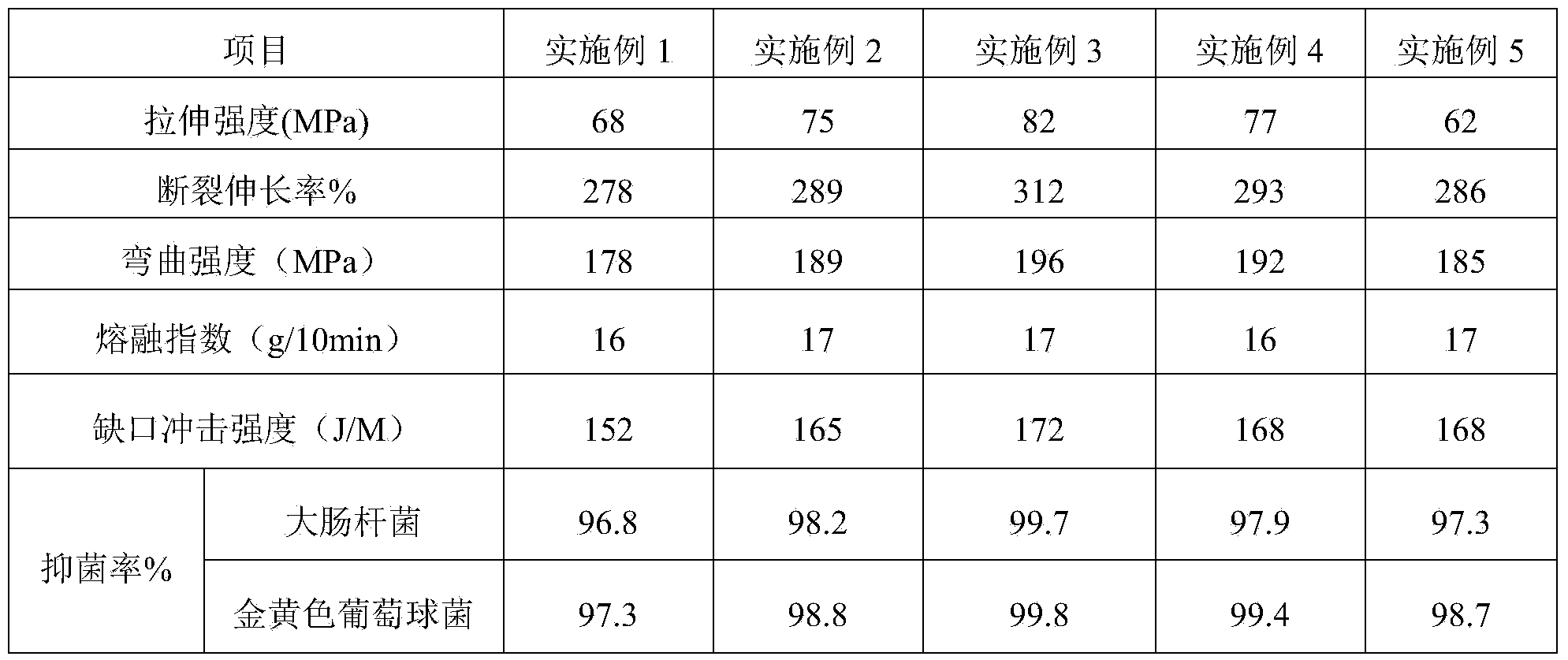

Examples

Embodiment 1

[0017] A medical composite antibacterial tube, comprising: 40 parts of PVC, 10 parts of polycarbonate, 30 parts of PE; 8 parts of PET; 3 parts of silver powder; 0.8 parts of potassium phosphate; 1 part of calcium oxide; 1 part of acid diester; 5 parts of butyl rubber; 0.8 part of stearic acid; 3 parts of titanium dioxide; 3 parts of polyethylene wax; 1 part of epoxy soybean oil; 0.8 part of barium stearate; 1 part of polyester fiber; Anhydride 2 parts.

[0018] The preparation method of above-mentioned medical compound antibacterial tube, comprises the following steps:

[0019] Step 1: Stir and mix each component in a mixing mixer according to parts by weight. The conditions for uniform stirring and mixing are as follows: a stirring speed of 220 rpm, a stirring time of 20 minutes, and a stirring temperature of 50°C;

[0020] Step 2, adding the mixed material in step 1 into a grinder, grinding until the particle size of the material is 400 μm, and then discharging;

[0021] S...

Embodiment 2

[0024] A medical composite antibacterial tube, comprising: 42 parts of PVC, 15 parts of polycarbonate, 32 parts of PE; 10 parts of PET; 4 parts of nano-silver powder; 1 part of potassium phosphate; 2 parts of calcium oxide; 2 parts of propionate diester; 7 parts of butyl rubber; 1.4 parts of stearic acid; 6 parts of titanium dioxide; 5 parts of polyethylene wax; 3 parts of epoxy soybean oil; 1 part of barium stearate; 3 parts of polyester fiber; 4 parts of anhydride.

[0025] The preparation method of above-mentioned medical compound antibacterial tube, comprises the following steps:

[0026] Step 1: Stir and mix each component in a mixing mixer according to parts by weight. The conditions for uniform stirring and mixing are as follows: a stirring speed of 220-280 rpm, a stirring time of 25 minutes, and a stirring temperature of 52°C;

[0027] Step 2, adding the mixed material in step 1 into a grinder, grinding until the particle size of the material is 450 μm, and then disch...

Embodiment 3

[0031] A medical composite antibacterial tube, comprising by weight components: 45 parts of PVC, 17 parts of polycarbonate, 33 parts of PE; 12 parts of PET; 5 parts of nano-silver powder; 1.3 parts of potassium phosphate; 3 parts of calcium oxide; 3 parts of propionate diester; 8 parts of butyl rubber; 1.6 parts of stearic acid; 7 parts of titanium dioxide; 6 parts of polyethylene wax; 4 parts of epoxy soybean oil; 1.2 parts of barium stearate; 4 parts of polyester fiber; 5 parts of anhydride.

[0032] The preparation method of above-mentioned medical compound antibacterial tube, comprises the following steps:

[0033] Step 1: Stir and mix each component in a mixing mixer according to parts by weight. The conditions for uniform stirring and mixing are as follows: a stirring speed of 260 rpm, a stirring time of 35 minutes, and a stirring temperature of 58°C;

[0034] Step 2, adding the mixed material in step 1 into a grinder, grinding until the particle size of the material is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com