Preparation method of nanopowder-based composite thermal insulation material

A technology of nano-powder and heat-insulating material, applied in the field of heat-insulating material, can solve the problems of high energy consumption in the supercritical drying process, complicated preparation process, difficult production, etc., so as to achieve no potential safety hazard, simple preparation process, and improved mechanics. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

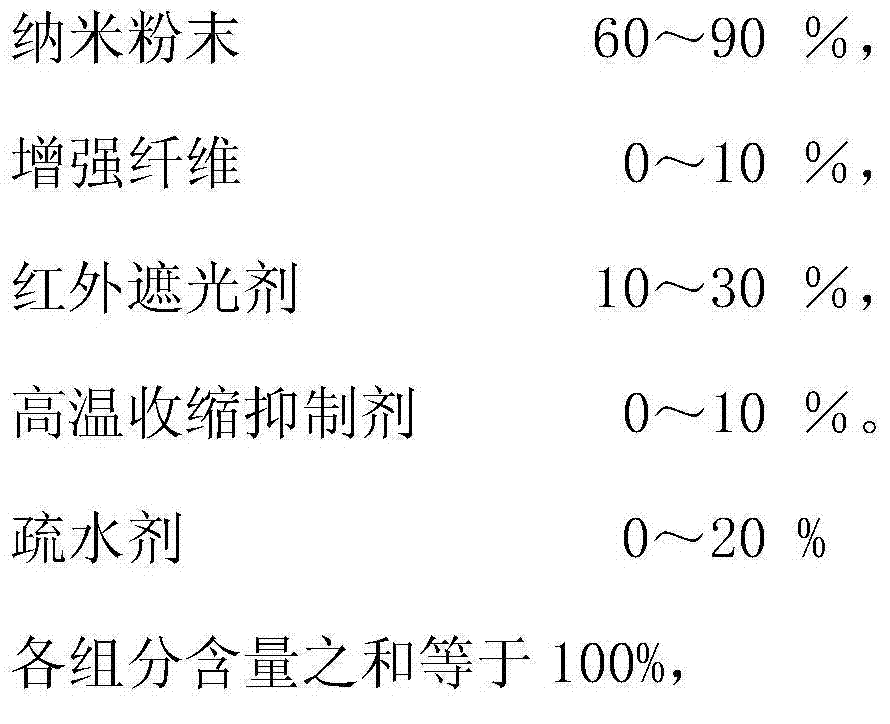

[0020] SiO by gas phase method 2 70wt%, SiC25wt%, 5% alkali-free ultra-fine glass fiber with a length of 5mm, add it to the high-speed modified dispersion device, run it at 1200 speed for 30 minutes, take out the mixed material and put it into the mold, and then use a hydraulic press to The molding pressure was pressed into a block material with a size of 80mm×20mm×20mm, and finally the block material was pressed at a pressing speed of 1N / s until the sample ruptured. The results showed that the block composite insulation The strength increased from 0.05MPa without adding reinforcing fibers to 0.29MPa.

Embodiment 2

[0022] SiO by gas phase method 2 70wt%, SiC25wt%, 5% non-alkali ultrafine glass fiber with a length of 5mm, add it to the high-speed modified dispersion device, run it at 1200 rpm for 30 minutes, take out the mixed material and put it into the mold, and then use a hydraulic press to The molding pressure was pressed into a block material with a size of 100mm×100mm×14.3mm. Finally, the thermal conductivity of the sample was measured by the hot wire method. The results showed that after adding the opacifying agent, the thermal insulation performance of the sample was greatly improved. From 0.119W / (m·K) without adding opacifying agent to 0.044W / (m·K).

Embodiment 3

[0024] SiO by gas phase method 2 70wt%, gas phase method Al 2 o 3 5wt%, SiC20wt%, 5% alkali-free ultra-fine glass fiber with a length of 5mm, add it to the high-speed modified dispersion device, run it at 1200 rpm for 30 minutes, take out the mixed material and put it into the mold, and then use a hydraulic press to The molding pressure is pressed and molded, then calcined at 1000°C, and kept for 1h, and finally the sample is taken out to measure its volume shrinkage. The results show that adding the gas-phase method Al 2 o 3 Finally, the shape shrinkage of the sample at high temperature is significantly improved, and the volume stability is significantly improved. At 1000°C, the volume shrinkage rate decreased from 18.49% to 3.47%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com