Ventilation air methane combustion catalyst and preparation method thereof

A methane combustion and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as complex processes, limited catalytic activity of catalysts, complex preparation methods, etc., to achieve cost reduction and meet thermal stability Requirements for sex and low temperature activity, and the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

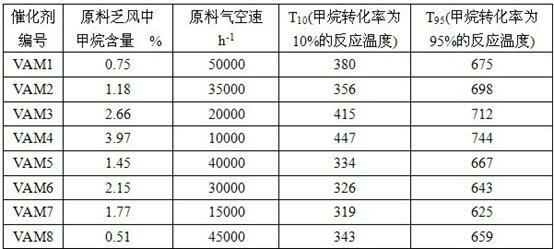

Examples

Embodiment 1

[0040] The composition of present embodiment catalyst is:

[0041] 1% active component, 30% coagent and 69% carrier, the active component is cobalt nitrate equivalent to 1% cobalt oxide, the coagent is cerium nitrate equivalent to 30% ceria, and the carrier It is 69% alumina, named VAM1.

[0042] The catalyst is prepared by the following method:

[0043] (1), 3.9g of cobalt nitrate hexahydrate (equivalent to 1g of cobalt oxide), 76g of cerium nitrate hexahydrate (equivalent to 30g of cerium dioxide) were dissolved in 100g of 5wt% citric acid aqueous solution to form a solution;

[0044] (2), immerse 69g of alumina in the aqueous solution prepared in step (1), and immerse at room temperature for 4 hours;

[0045] (3) Extrude the mixture in step (2), dry at 120°C for 1 hour, and calcinate at 600°C for 4 hours to obtain a strip catalyst.

Embodiment 2

[0047] The composition of present embodiment catalyst is:

[0048] 50% active component, 1% coagent and 49% carrier, the active component is cobalt acetate which is equivalent to 50% cobalt oxide content, and the coagent is nitric acid which is equivalent to 1% lanthanum trioxide content Lanthanum, the carrier is composed of 20% titanium oxide and 29% zirconium oxide, named VAM2.

[0049] The catalyst is prepared by the following method:

[0050] (1), 2.7 g of lanthanum nitrate hexahydrate (equivalent to 1 g of lanthanum trioxide) was dissolved in 50 g of citric acid aqueous solution with a concentration of 1 wt%, to form a solution;

[0051] (2) Dissolve 20g of titanium oxide and 29g of zirconium oxide in the aqueous solution prepared in step (1), immerse at room temperature for 3 hours, dry naturally, press into tablets, dry at 120°C for 2 hours, and bake at 500°C for 5 hours , that is, the catalyst precursor is obtained.

[0052] (3) Dissolve 166g of cobalt acetate tetra...

Embodiment 3

[0054] The composition of present embodiment catalyst is:

[0055] 40% active ingredient, 20% coagent and 40% carrier, the active component is manganese nitrate equivalent to 20% manganese dioxide, and the coagent is lanthanum nitrate equivalent to 20% lanthanum trioxide , the carrier is 20% magnesium oxide and 40% calcium oxide, named VAM3.

[0056] The catalyst is prepared by the following method:

[0057] (1) Fully mix 116g of manganese nitrate tetrahydrate (equivalent to 40g of manganese dioxide), 20g of magnesium oxide and 40g of calcium oxide.

[0058] (2) The mixture is rolled into a ball, dried at 120°C for 2 hours, and calcined at 500°C for 2 hours to make a catalyst precursor;

[0059] (3) Dissolve 54g of lanthanum nitrate hexahydrate (equivalent to 20g of dilanthanum trioxide) in 150g of citric acid aqueous solution with a concentration of 10wt% to form a solution. The catalyst precursor in step (2) was immersed in the solution, soaked at room temperature for 6 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com