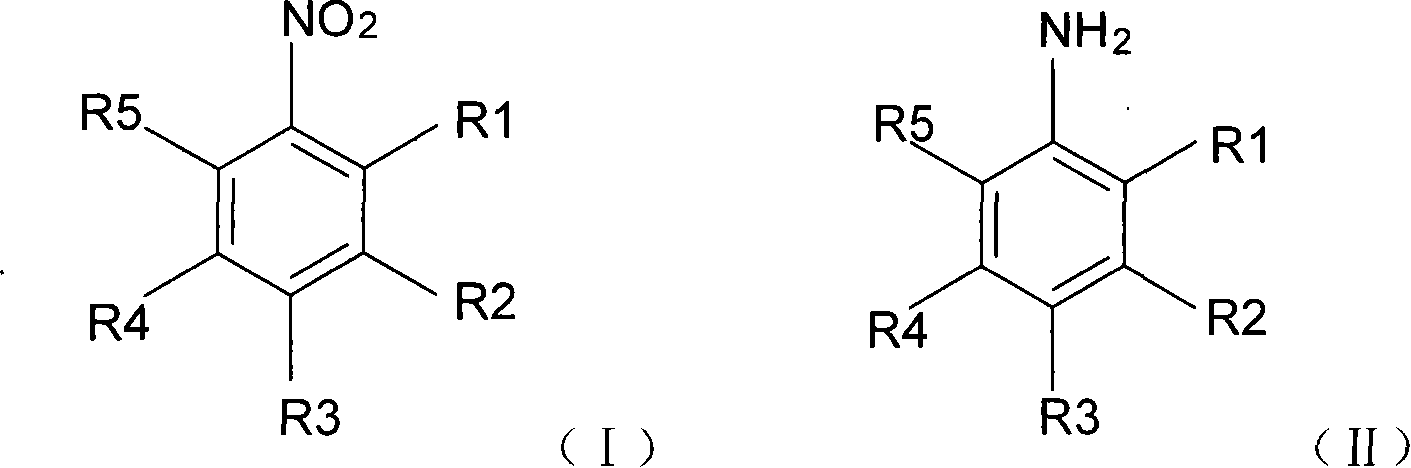

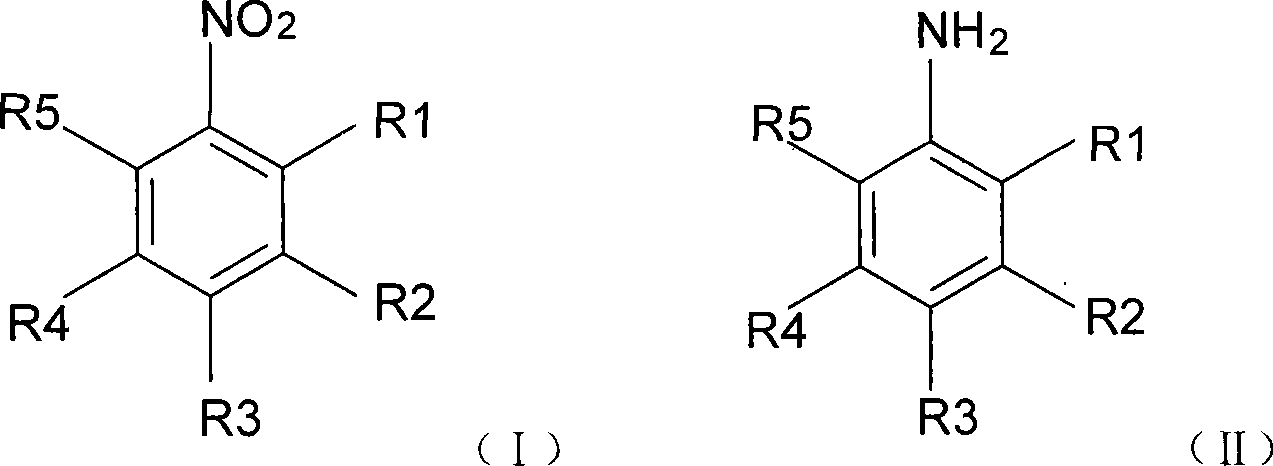

Method for preparation of (substituted radical containted) aminophenol by catalytic hydrogenation of (substituted radical containted) nitrophenol

A technology of nitrophenol and aminophenol, which is applied in the field of catalysts and catalytic reactions for the synthesis of aminophenol by hydrogenation of nitrophenol, and can solve problems such as poor product quality, environmental pollution, precious metal catalysts and difficulty in catalyst recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~19

[0013] Catalyst preparation:

[0014] Preparation of catalyst by mixing method Add a certain concentration of nickel nitrate aqueous solution and the soluble salt solution of component A or the oxide of component A to the catalyst carrier according to a certain metering ratio, mix evenly and extrude or tablet, and then heat at 120°C drying at 600°C for 4 hours. After the roasting is completed, it is lowered to room temperature, put into the reactor, and reduced with hydrogen at 450°C for 4 hours. After the reduction is completed, the conditions are adjusted to the conditions required for the reaction. The composition of catalyst in each embodiment, the kind of starting material of component A is shown in Table 1.

[0015]

Example

Component A

Component A

starting material

Carrier X

The mass of Ni

Min content, %

The quality of A

Min content, %

Example 1

co

γ-Al 2 o ...

Embodiment 20~28

[0024] 100 g of the catalyst in Example 15 was loaded into a fixed-bed tubular reactor, and reduced with hydrogen at 450° C. for 4 hours. After the reduction, the temperature was lowered to the reaction temperature. The p-nitrophenol with a mass fraction of 6% and hydrogen are mixed and preheated and then enter the reactor for reaction. The specific reaction conditions and reaction results in Examples 20-28 are shown in Table 5.

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com