Transparent or transparent dyed lithium aluminium silicate glass ceramic material having adapted thermal expansion and use thereof

A technology of lithium aluminosilicate and glass ceramics, which is applied in solid heating fuel, thin material processing, household stoves/stoves, etc., can solve the problems of reducing the temperature of glass ceramic windows, and achieve the purpose of avoiding visual distortion, reducing stress, and improving effect of opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0189] The invention is illustrated by the following examples.

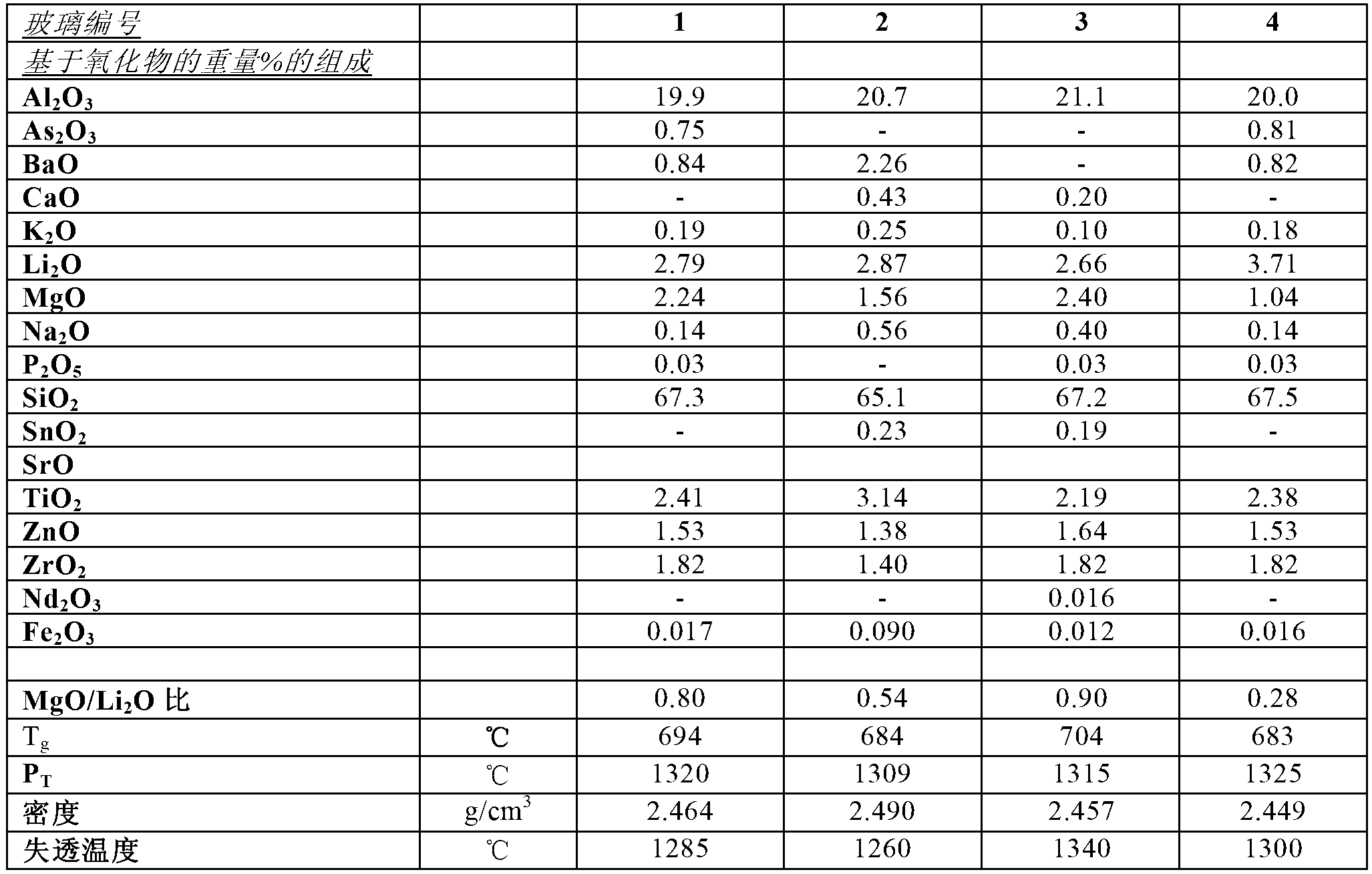

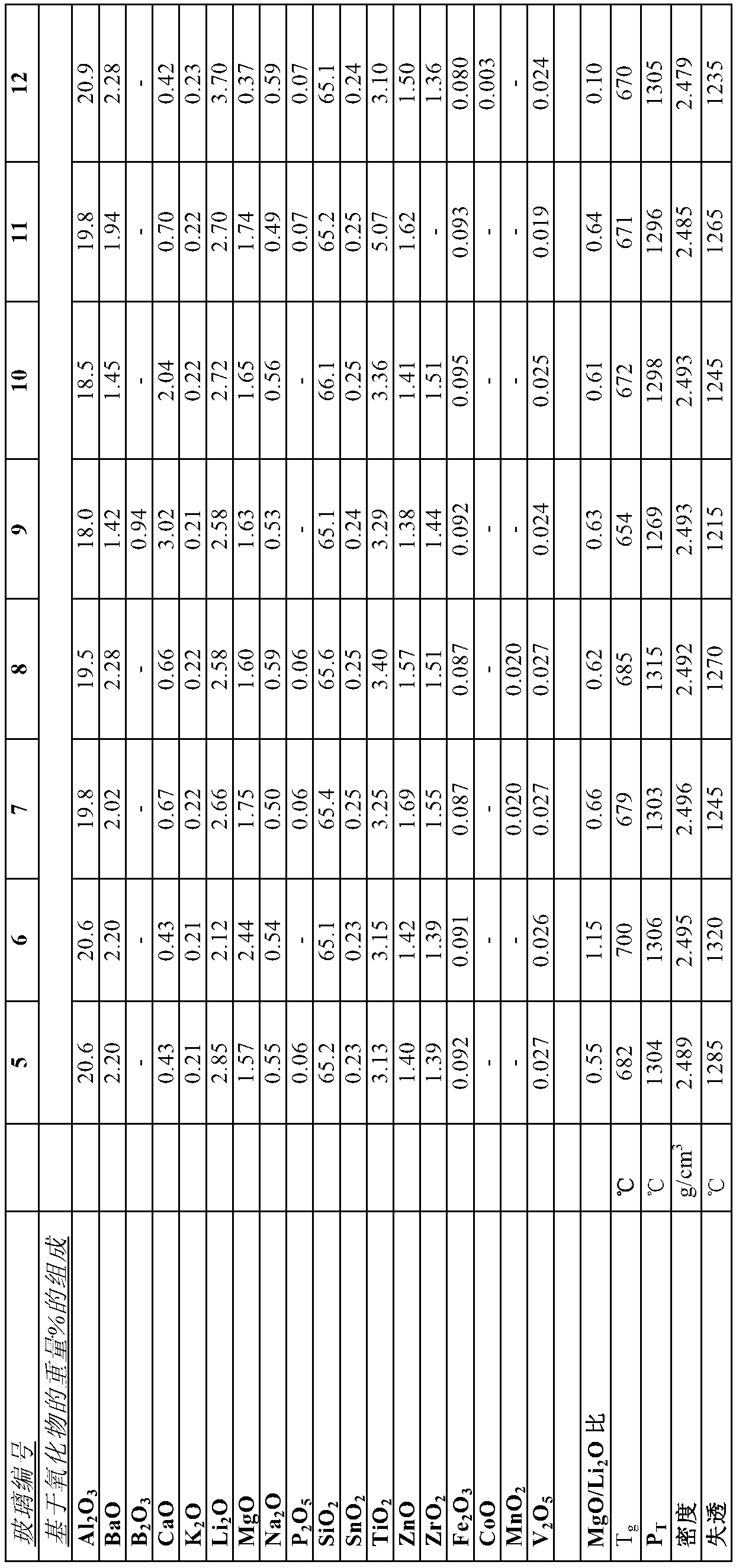

[0190] For some examples, the composition and properties of the crystallizable starting glass for transparent glass-ceramics are shown in Table 1. Here, glasses 1 to 3 are glasses according to the invention, whereas glass 4 is a comparative glass outside the scope of the invention. Table 2 shows the composition and properties of the crystallizable starting glasses for transparent colored glass-ceramics. Here, glasses 5 to 11 are glasses according to the invention, whereas glass 12 is a comparative glass outside the scope of the invention. Due to the impurities typical in industrial mixtures of the raw materials used, the composition does not add up to exactly 100% by weight. Although not intentionally introduced into the composition, typical impurities are F, Cl, B, P, Rb, Cs, Hf or Sr, which are usually present in amounts below 0.05% by weight. They are usually introduced via the raw materials used for the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com