Patents

Literature

36results about How to "Scientific and rational use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tobacco raw material classifying and grouping method

ActiveCN102920005AScientific useScientific and rational useTobacco preparationMaterial analysisChemical compositionGroup method

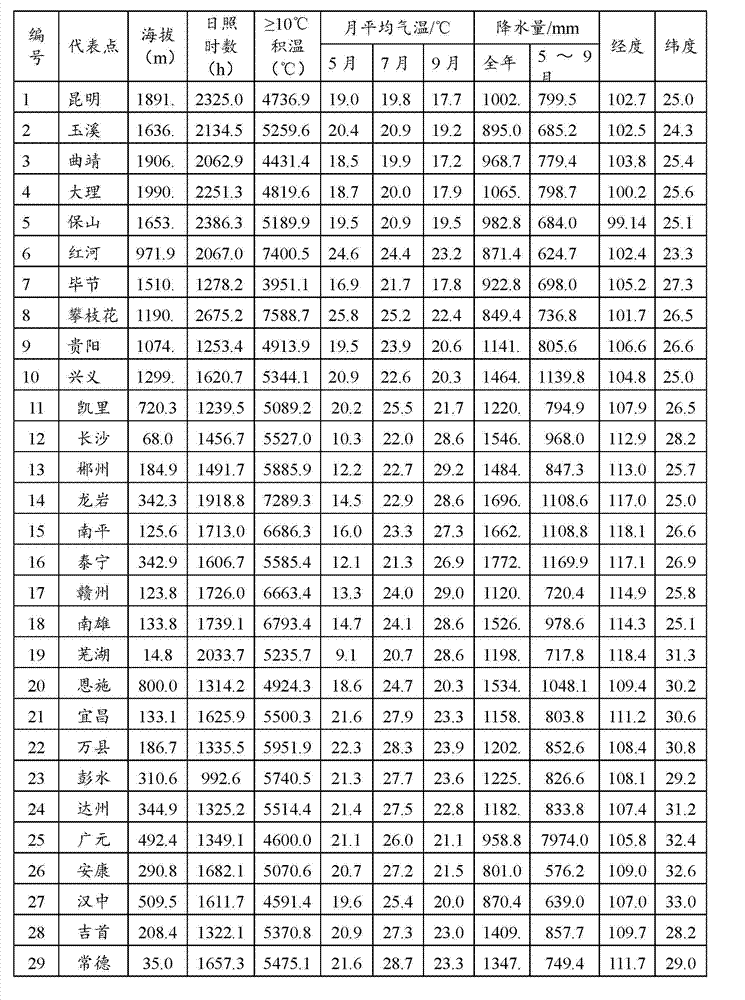

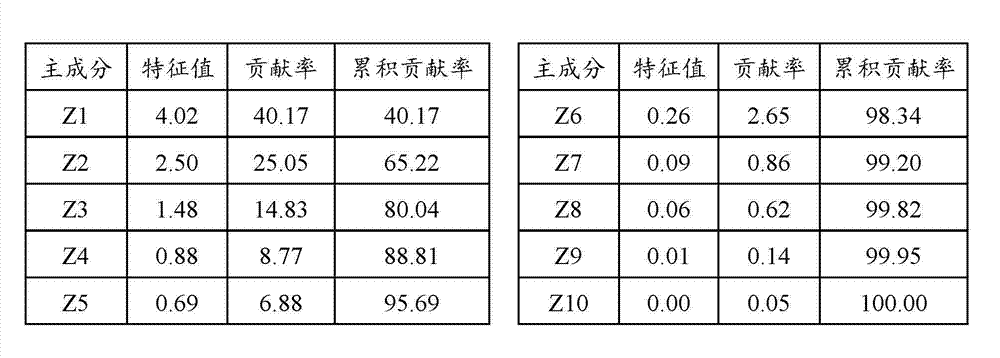

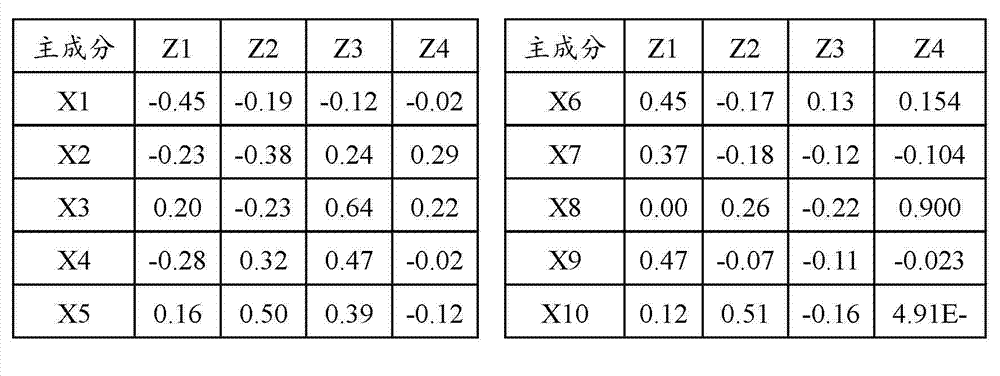

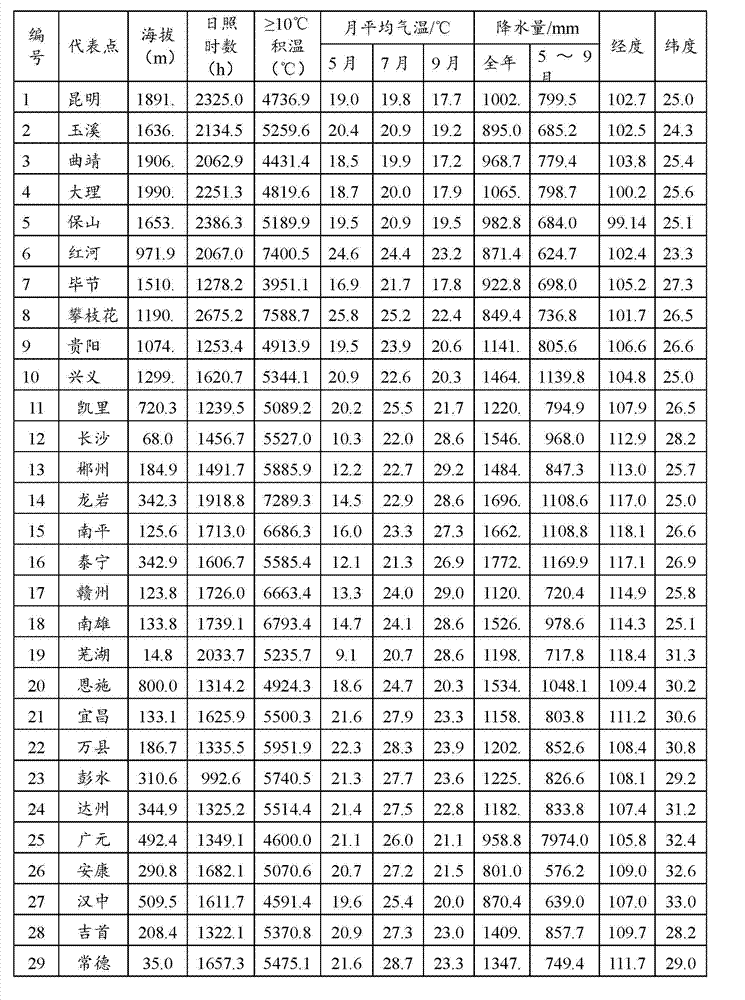

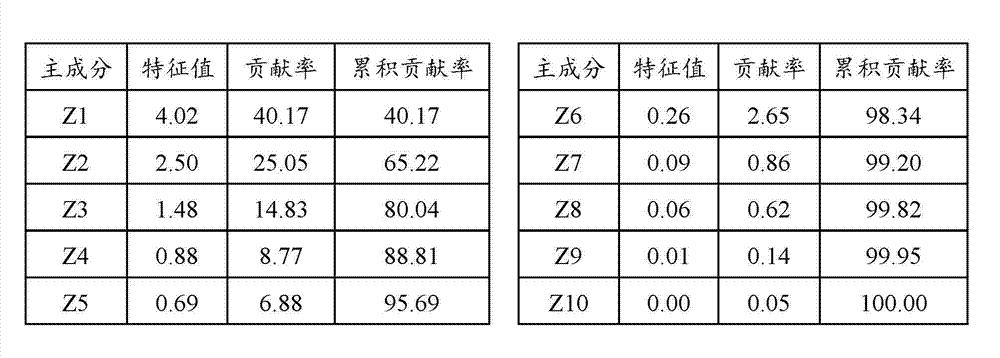

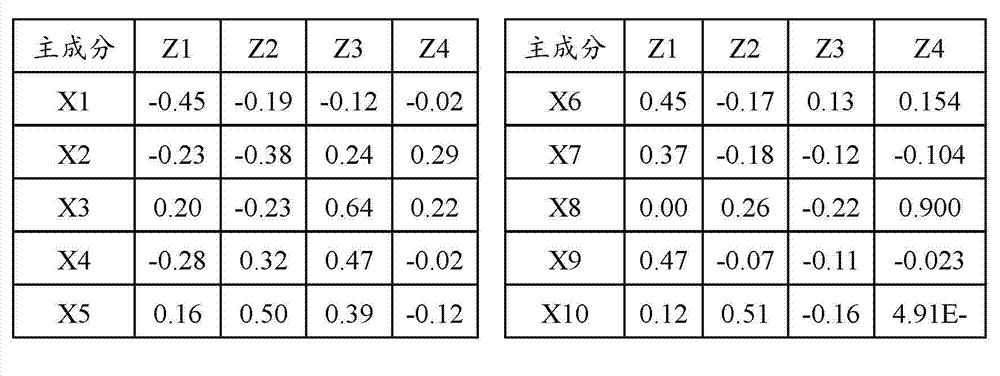

The invention discloses a tobacco raw material classifying and grouping method. The method comprises the steps as follows: collecting ecological information of a tobacco planting land, extracting the major component of the ecological information, analyzing the extracted major component with cluster analysis to obtain the classification result, and verifying the classification result; and after the tobacco raw materials are classified, collecting chemical constituent indexes of the tobacco raw materials, extracting the major component of the chemical constituent indexes, analyzing the major component with cluster analysis to obtain the grouping result, and verifying the grouping result. The method classifies the tobacco raw materials according to the ecological information of growth in terms of the characteristics of the tobacco raw materials as agricultural products, takes into consideration that the tobacco raw materials serve as the processing raw materials of industrialized products, and groups the tobacco raw materials in the same category according to the chemical constituents. The classifying and grouping method can provide scientific and reasonable guide and support for cigarette formulation design, threshing and redrying, and establishment of group processing module, facilitates the quality improvement of cigarette products, and draws on tobacco raw materials more scientifically and reasonably.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

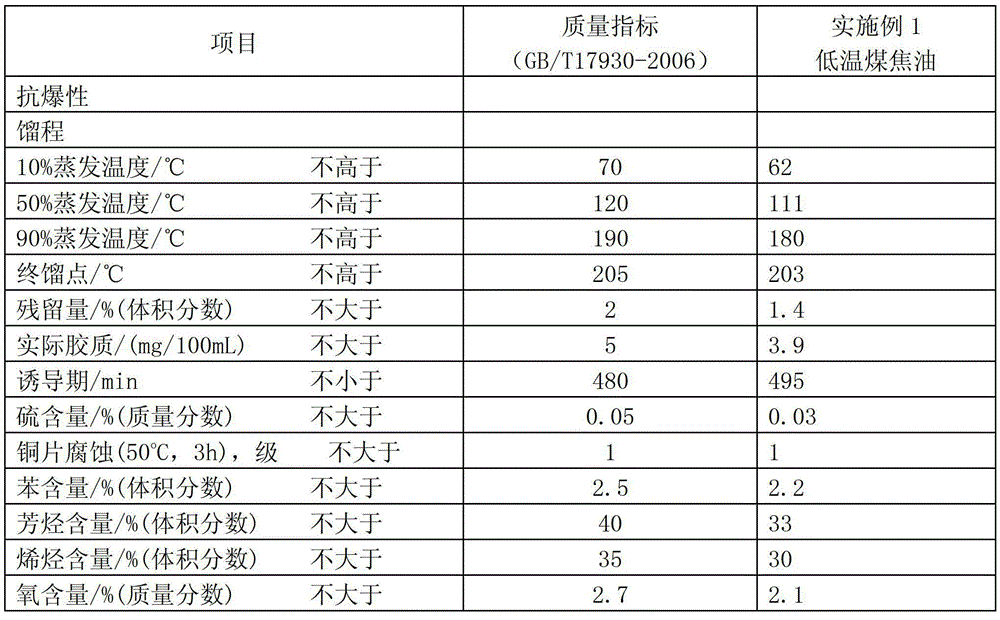

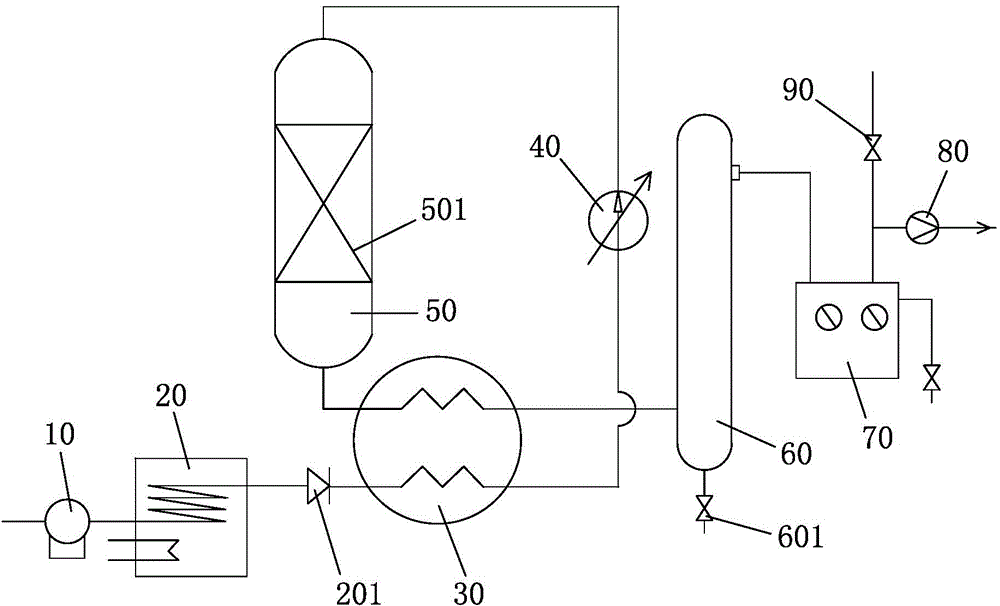

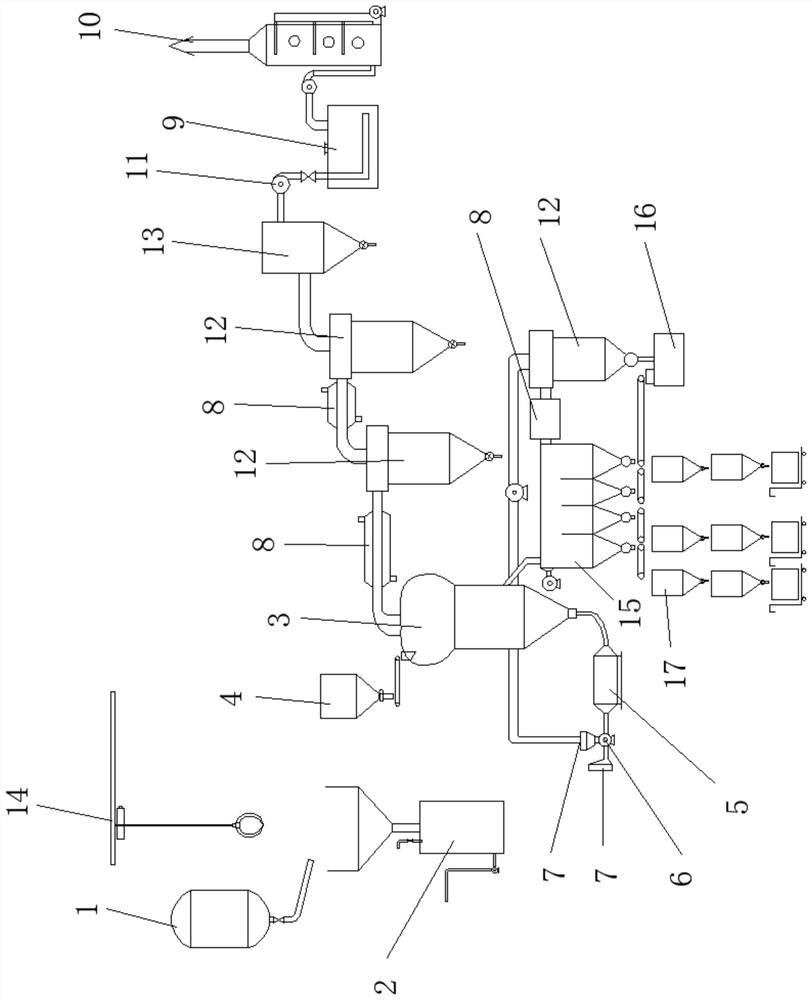

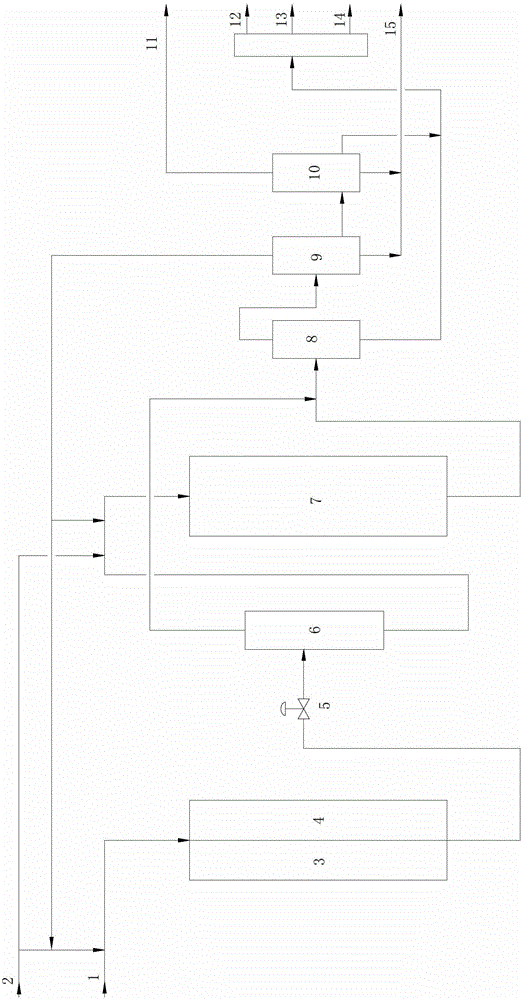

Method for producing fuel oil and lubricant base oil by hydrogenating all fractions of coal tar

ActiveCN103146424AScientific and rational useInsufficient reliefTreatment with hydrotreatment processesEconomic benefitsTar

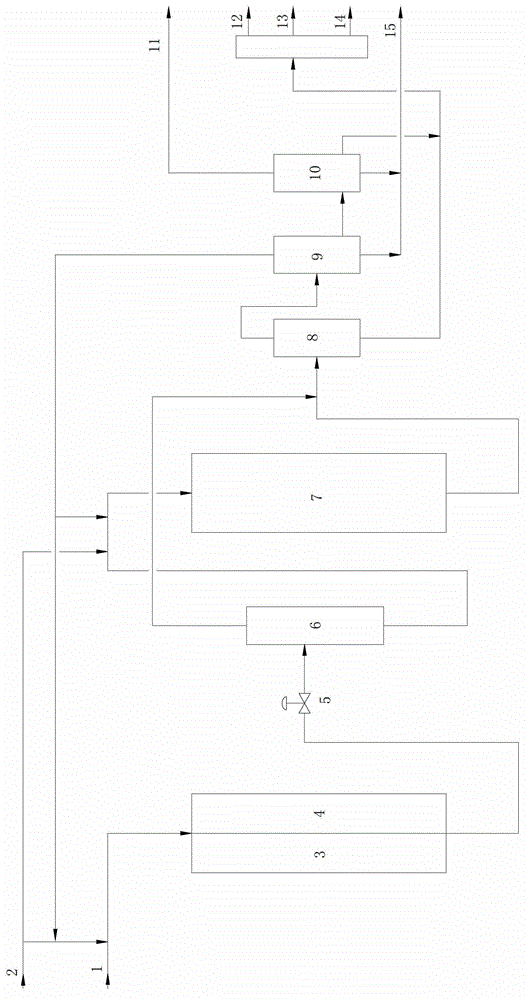

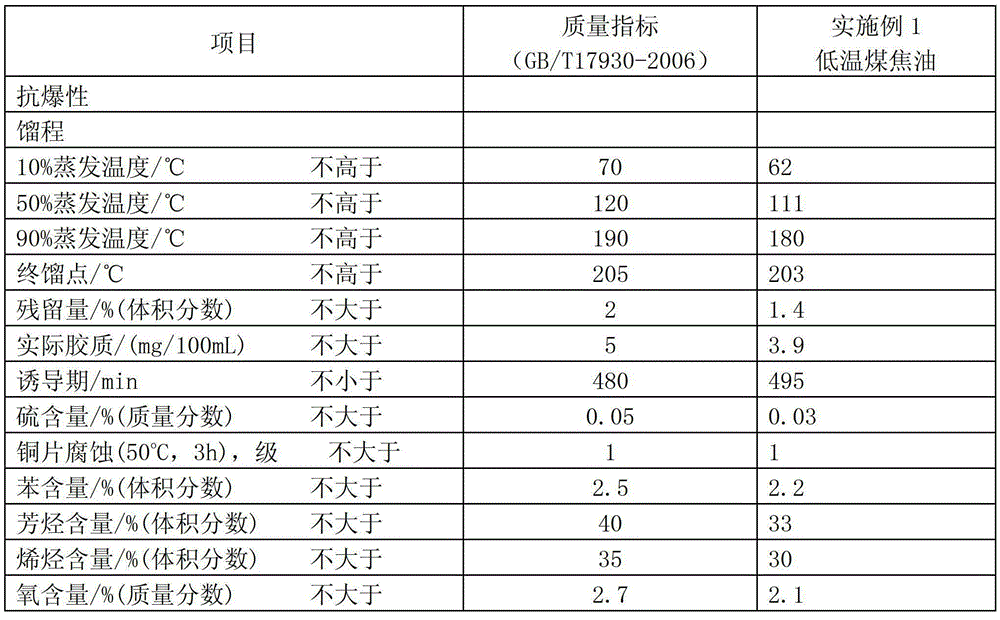

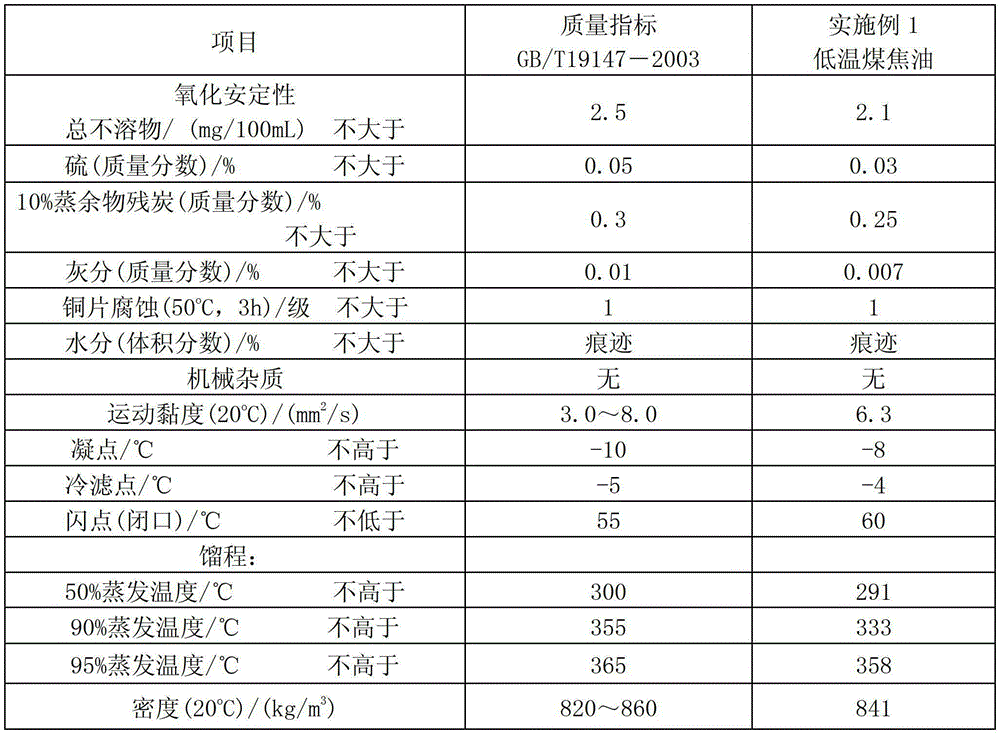

The invention relates to a method for producing fuel oil and lubricant base oil by hydrogenating all fractions of coal tar. The method comprises the following steps of: performing pressure reduction on the all fractions of coal tar by virtue of a pressure reduction valve after hydroprocessing on the all fractions of coal tar is finished, and flashing to separate out a light product and a heavy product; performing isodewaxing on the heavy product; and fractioning the heavy product, successively together with the light product, through a heat high fraction separator, a cold high fraction separator, a cold low fraction separator and a fraction tower to obtain the fuel oil and the lubricant base oil which are good in quality and meet a state standard request. The method is simple in process procedures, easy to control, and safe and stable in operation; and the all fractions of coal tar can be scientifically and reasonably utilized, the production economic benefit is further improved, and a certain active function in overcoming the defect of the fuel oil and the lubricant base oil in China is achieved.

Owner:SHENMUFUYOU ENERGY TECH

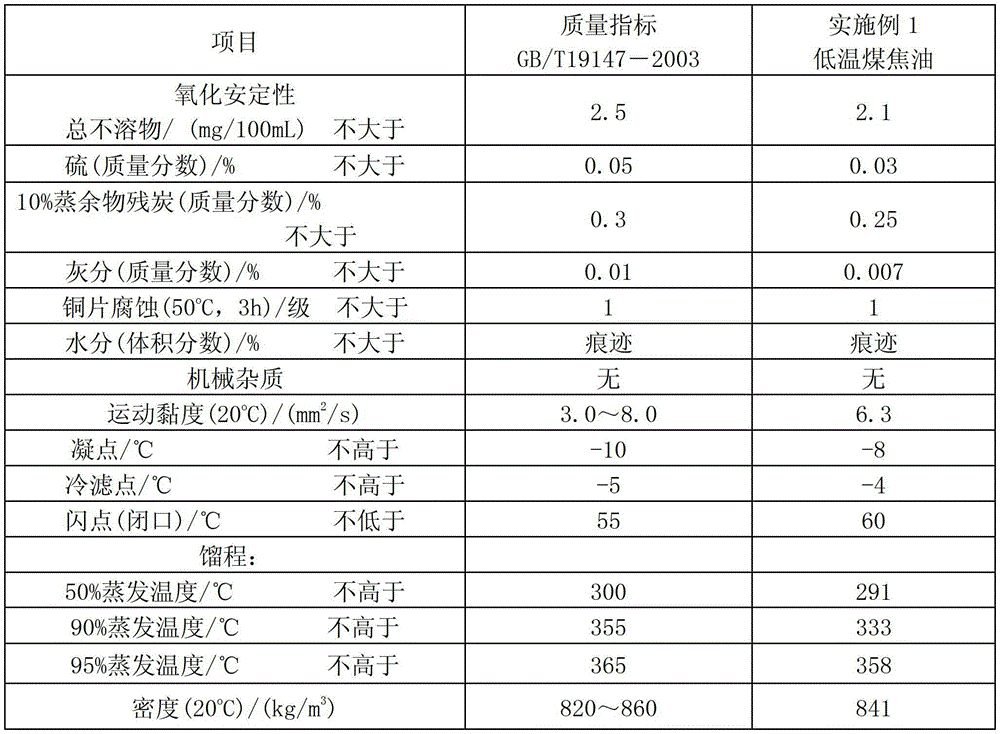

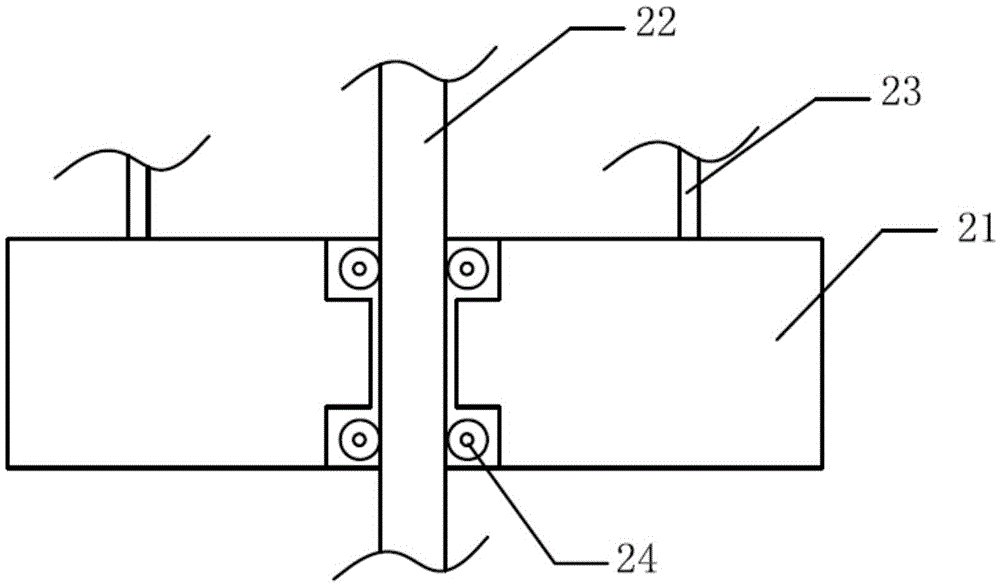

Multi-node AC test method implemented by aid of fatigue test machines matched with 4U jigs

InactiveCN106201797AImprove test efficiencySimple test kitDetecting faulty hardware by power-on testFatigue testingAC power

The invention discloses a multi-node AC test method implemented by the aid of fatigue test machines matched with 4U jigs, and belongs to the field of server test technologies. The multi-node AC test method implemented by the aid of the fatigue test machines matched with the 4U jigs includes executing test scripts on main test nodes and enabling the main test nodes to execute waiting operation if detected auxiliary test nodes are in on startup and shutdown states; enabling the main test nodes to execute shutdown operation if the detected auxiliary test nodes are in off startup and shutdown states; carrying out AC power off after the main test nodes detected by the fatigue test machines are shut down, keeping time for power-off time delay and powering up the test nodes again after the time for the power-off time delay of the fatigue test machines is up. The power-off time delay is set for the fatigue test machines. The multi-node AC test method implemented by the aid of the fatigue test machines matched with the 4U jigs has the advantages that test resources can be scientifically and reasonably utilized, the test efficiency can be improved, and accordingly the multi-node AC test method has excellent popularization application value.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

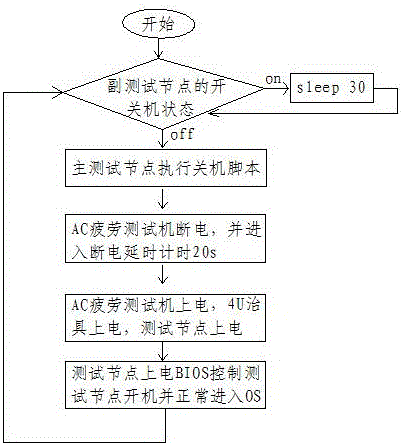

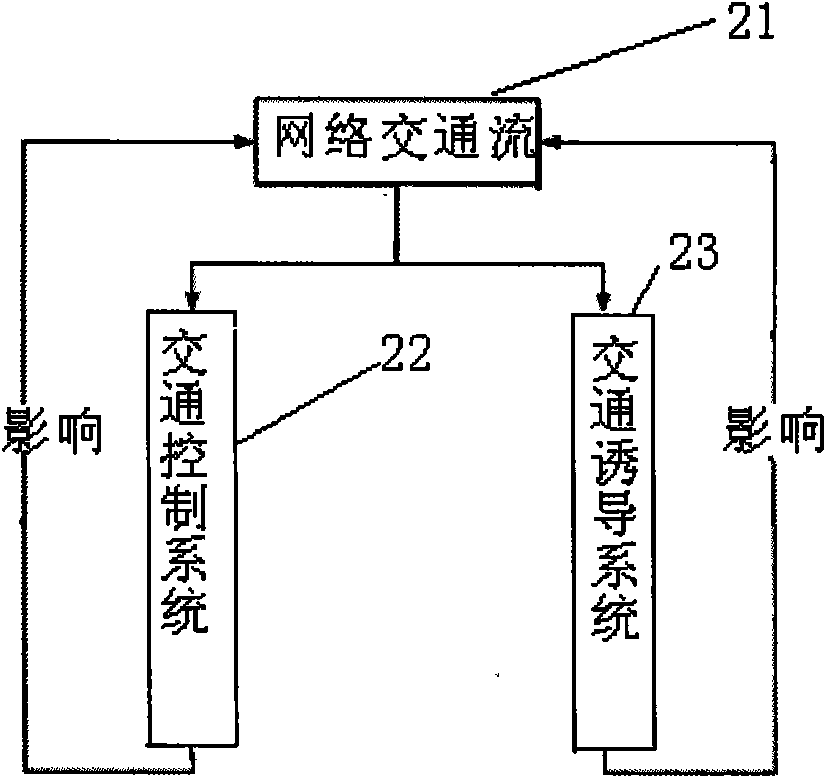

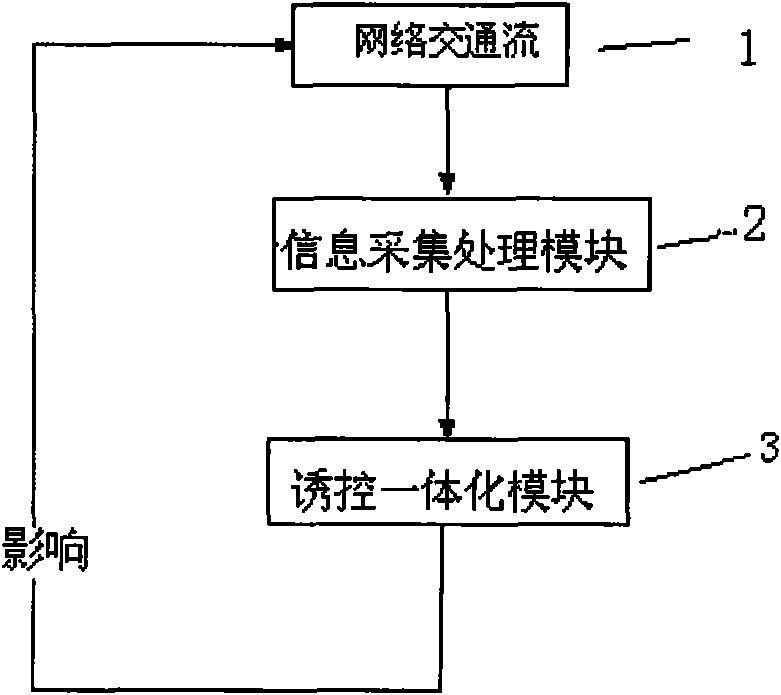

Real-time traffic guidance and control integrated system and implementation method thereof

InactiveCN101894466AReasonable spatial distribution of traffic flowResolve accuracyDetection of traffic movementInformation processingProcess module

The invention provides a real-time traffic guidance and control integrated system and an implementation method thereof. A real-time traffic guidance and control integrated coordination system is applied to the network traffic flow. The real-time traffic guidance and control integrated system comprises an information acquisition and processing module and a guidance and control integrated module, wherein the information acquiring and processing module comprises an information acquisition unit which is arranged on an information acquisition site and is used for acquiring traffic information and an information processing unit for pre-processing the traffic information; the guidance and control integrated module comprises a signal control optimizing unit for producing traffic control parameters, a traffic state judging unit for producing initial traffic state information and a traffic state issuing unit for producing road traffic state information; and the guidance and control integrated module receives the pre-processed traffic information and generates a traffic control and guidance scheme applied to the network traffic flow.

Owner:SHANGHAI BAOKANG ELECTRONICS CONTROL ENG

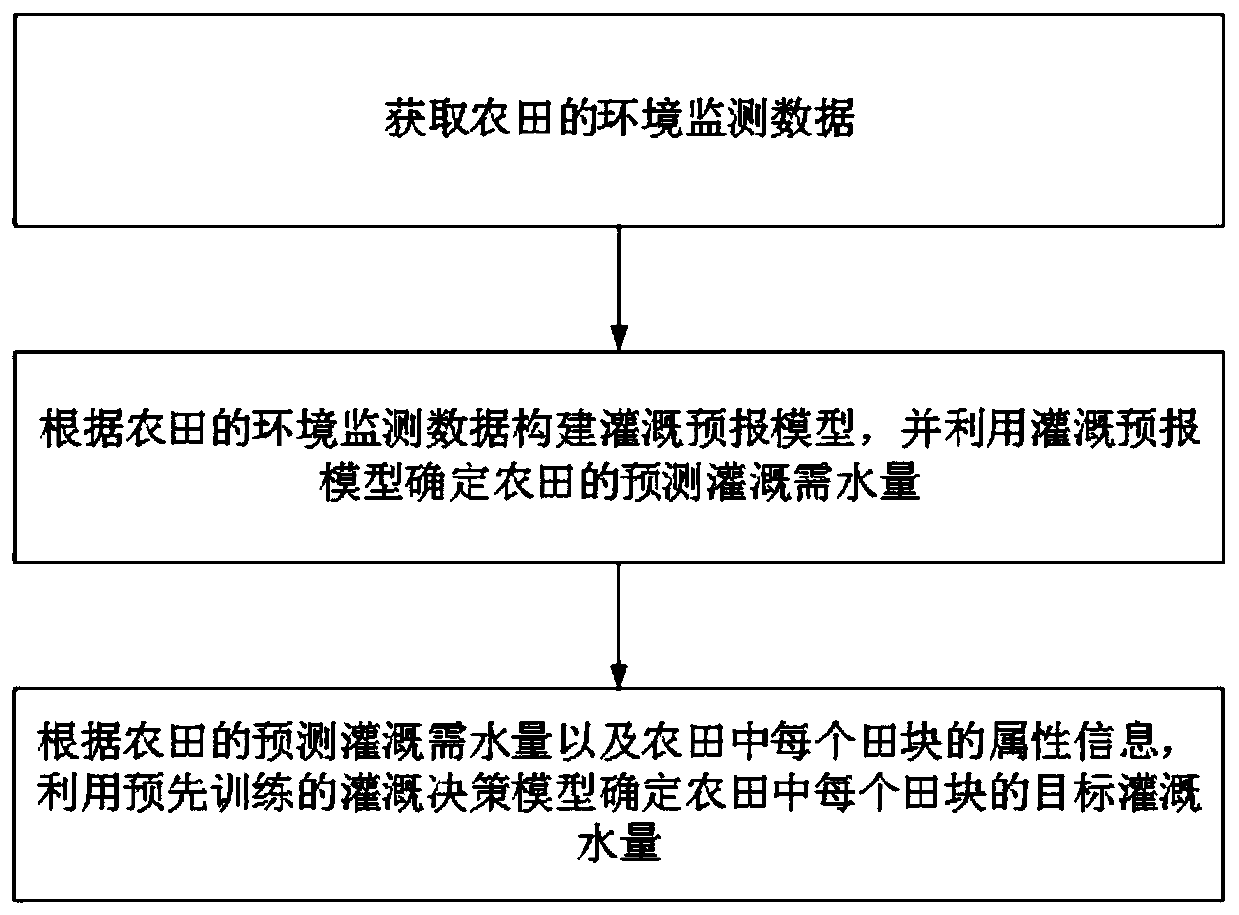

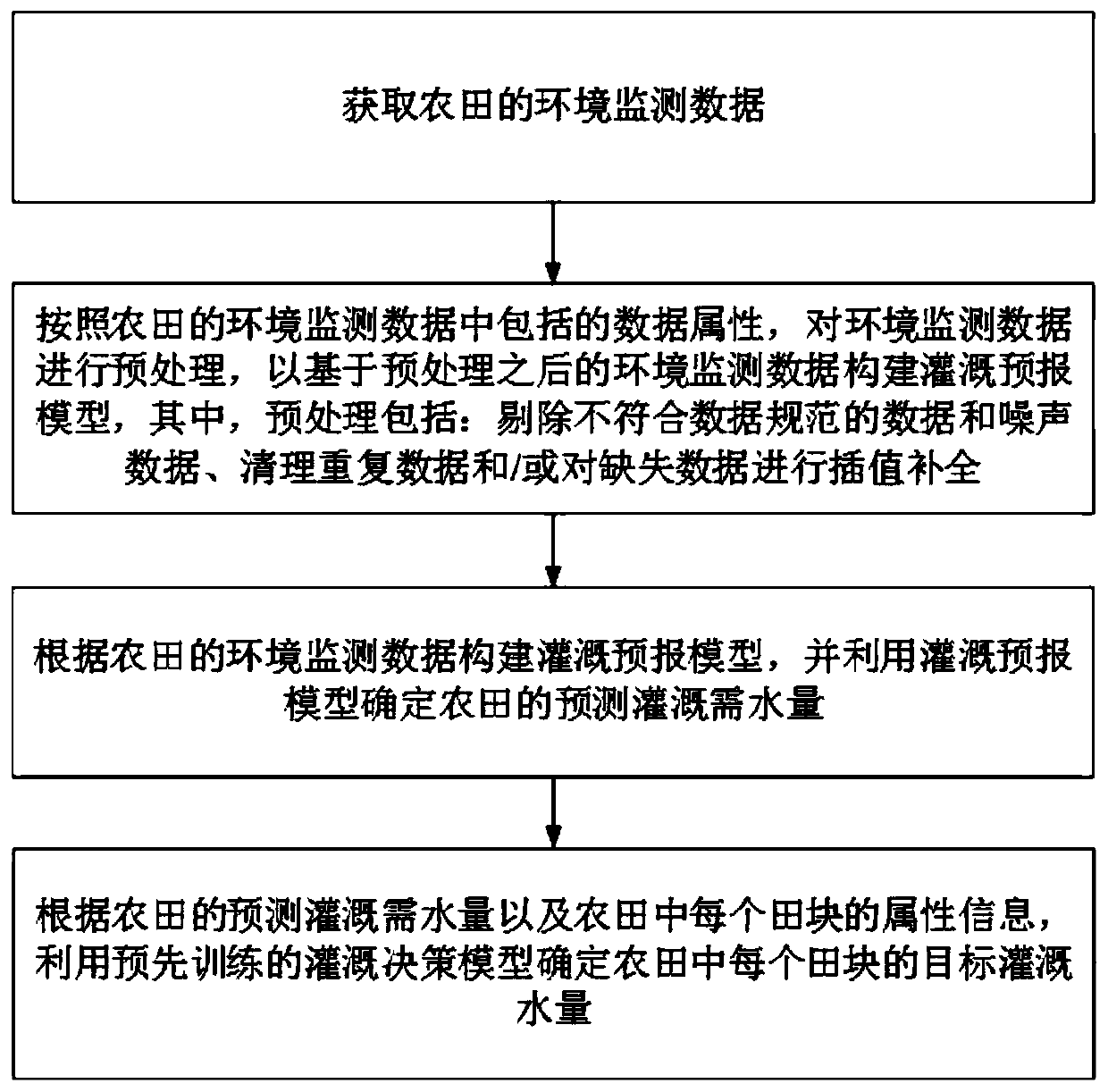

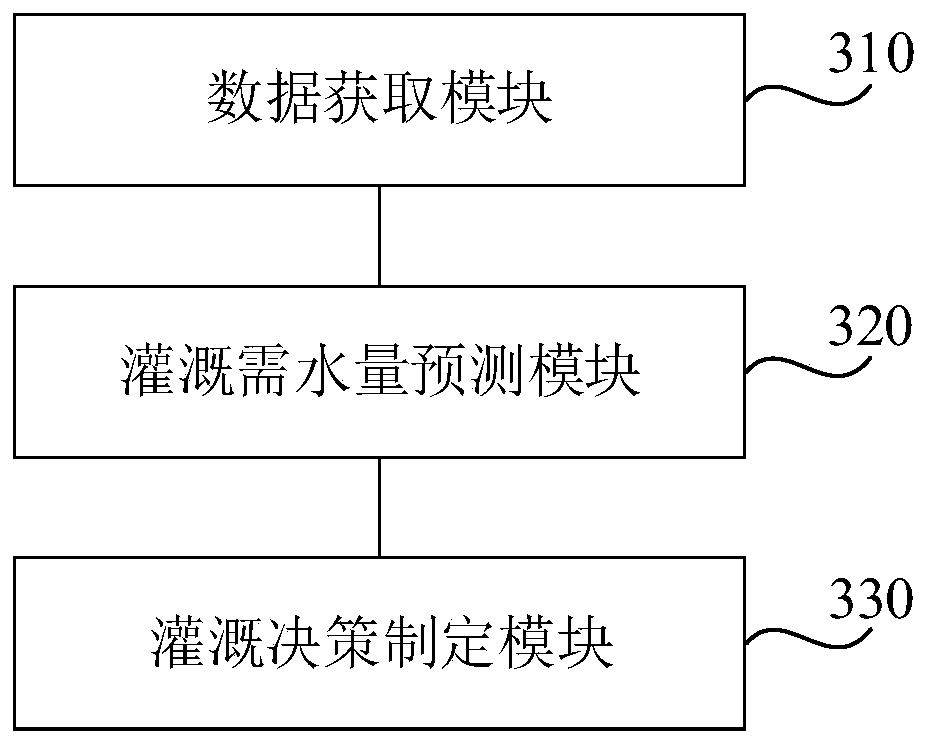

Irrigation decision making method and device based on big data, server and medium

ActiveCN111126662AResolve accuracySolve the costForecastingMachine learningEnvironmental resource managementDecision model

The invention relates to an irrigation decision making method based on big data. The method comprises the steps of obtaining farmland environment monitoring data; constructing an irrigation forecasting model according to the environmental monitoring data of the farmland, and determining a predicted irrigation water demand of the farmland by utilizing the irrigation forecasting model; and accordingto the predicted irrigation water demand of the farmland and the attribute information of each piece of field in the farmland, determining the target irrigation water quantity of each piece of fieldin the farmland by utilizing a pre-trained irrigation decision model. The device comprises a data acquisition module, an irrigation water demand prediction module and an irrigation decision making module which are electrically connected in sequence. A server includes: one or more processors; a storage device which is used for storing one or more programs, wherein when the one or more programs areexecuted by the one or more processors, the one or more processors implement the formulating method. A computer-readable storage medium on which a computer program is stored, the program implementes aformulating method when being executed. The utilization rate of irrigation water resources is improved.

Owner:CAMCE WHU DESIGN & RES CO LTD

Chinese toon leaf decocting pieces assisting in blood glucose reduction and preparation method of decocting pieces

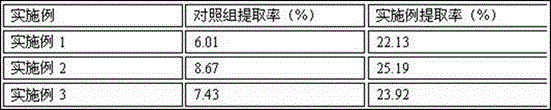

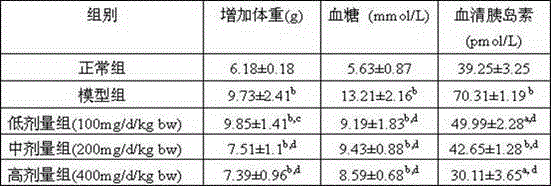

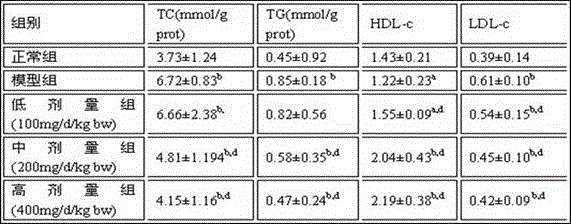

InactiveCN105832820AGuaranteed chemical propertiesHigh extraction rateMetabolism disorderPharmaceutical non-active ingredientsDiabetic complicationFlavones

The invention relates to Chinese toon leaf decocting pieces assisting in blood glucose reduction and a preparation method of the decocting pieces, and belongs to the field of a medical health-care product. The decocting pieces comprise the following components, by mass, 6-9% of a toon leaf extract, 12-14% of maltodextrin, and 0.5-0.75% of a lubricant, with the balance being a filling agent. The decocting pieces are prepared by performing room-temperature soaking, low-temperature soaking, room-temperature standing, ultrasonic extraction, and purification to old Chinese toon leaves to obtain the toon leaf extract; uniformly mixing the toon leaf extract, maltodextrin, and the filling agent, and carrying out sieving, soft material preparation, granulation, drying, addition of the lubrication and tabletting. Through the method, the general flavones extraction ratio is high, and active components of the extract can be effectively kept. Meanwhile, old Chinese toon leaves are subjected to reasonable exploitation and utilization, thereby increasing the use ratio and additional value of Chinese toon resources. The provided decocting pieces are convenient to eat, have an obvious effect on assisting blood glucose reduction, and can effectively prevent diabetic complications.

Owner:NORTHWEST A & F UNIV

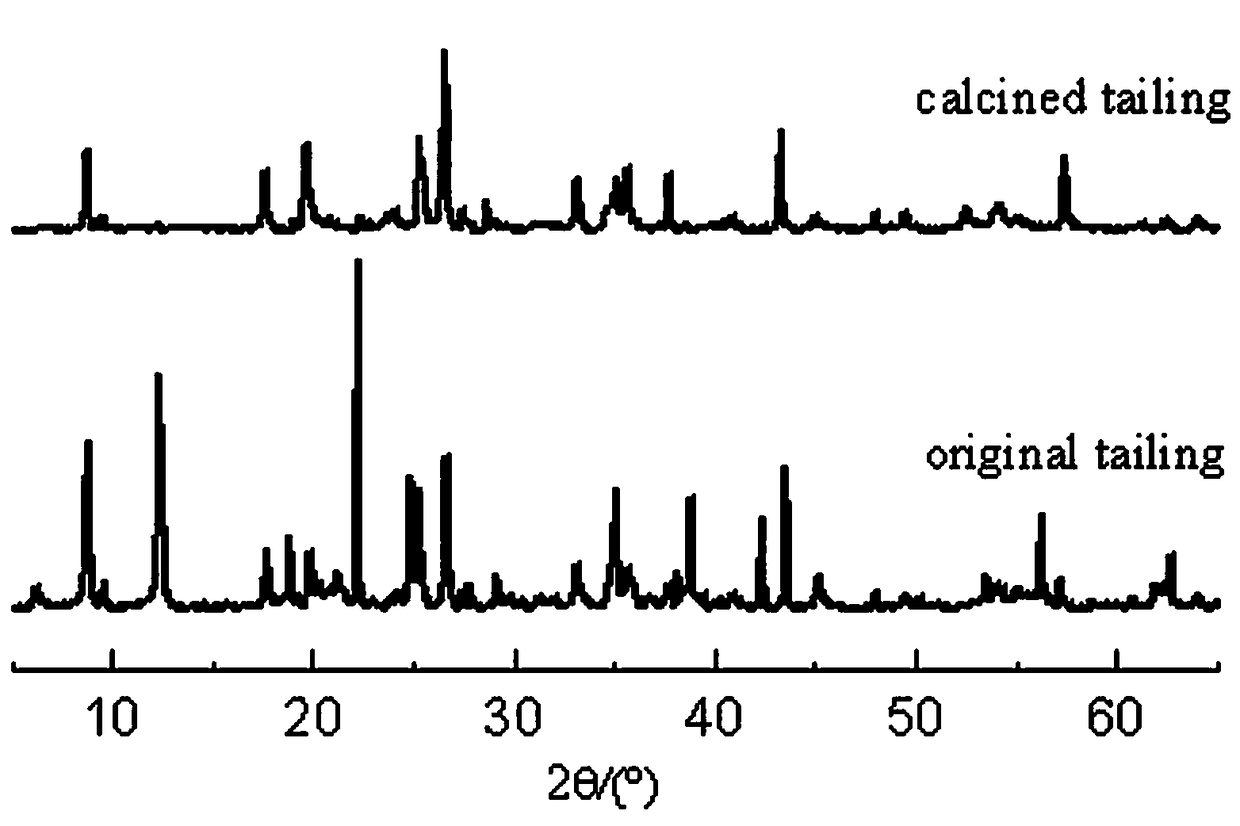

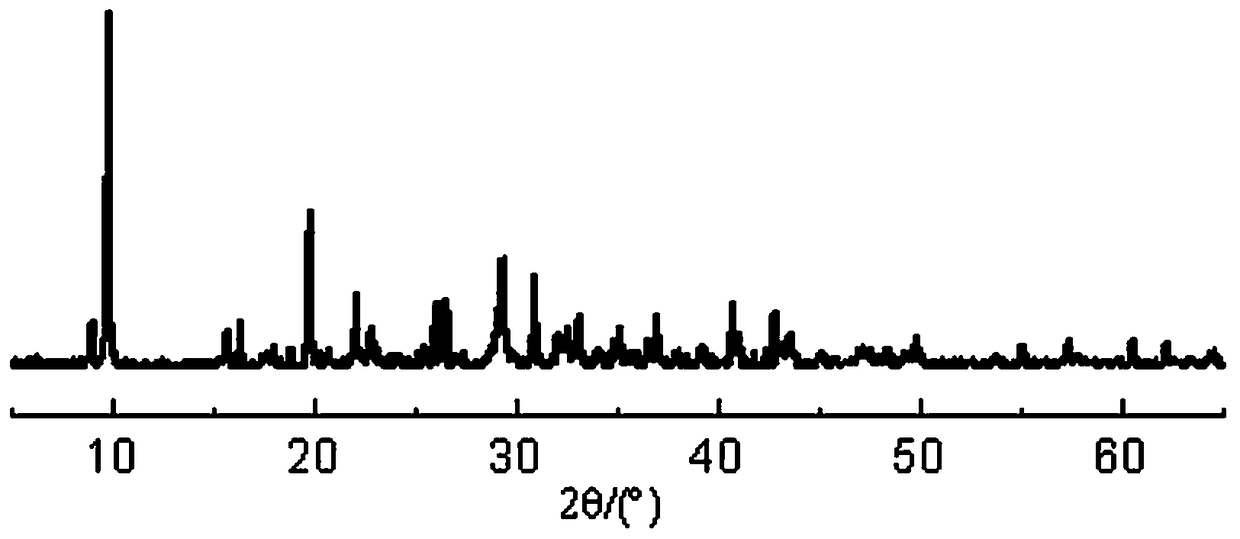

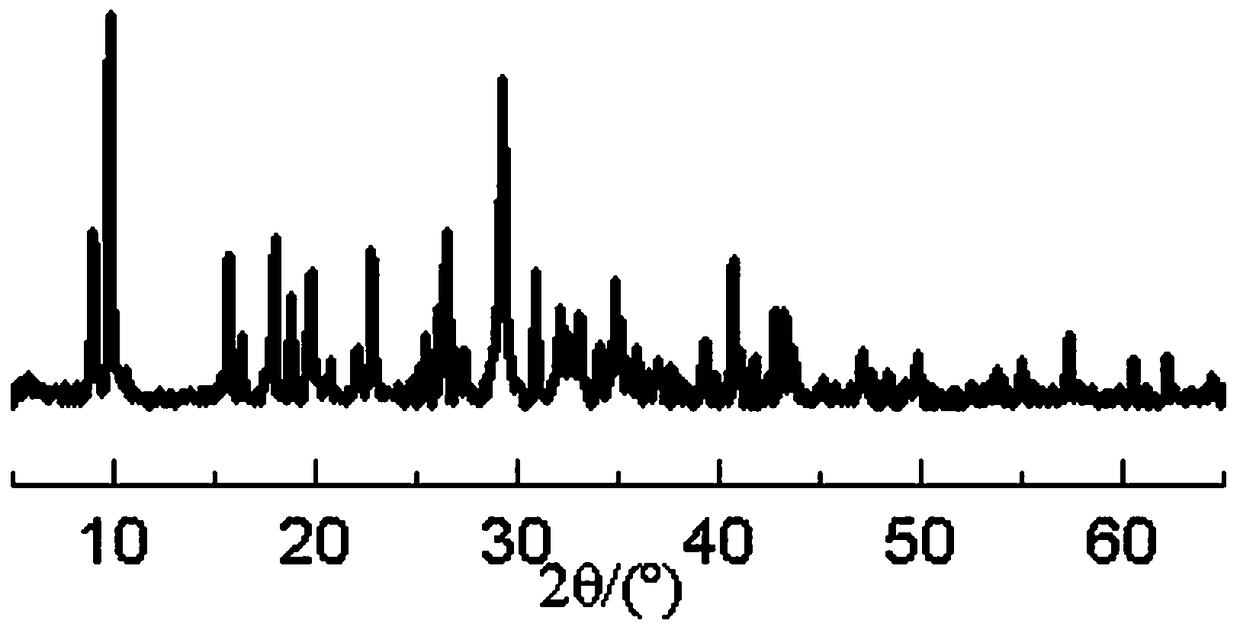

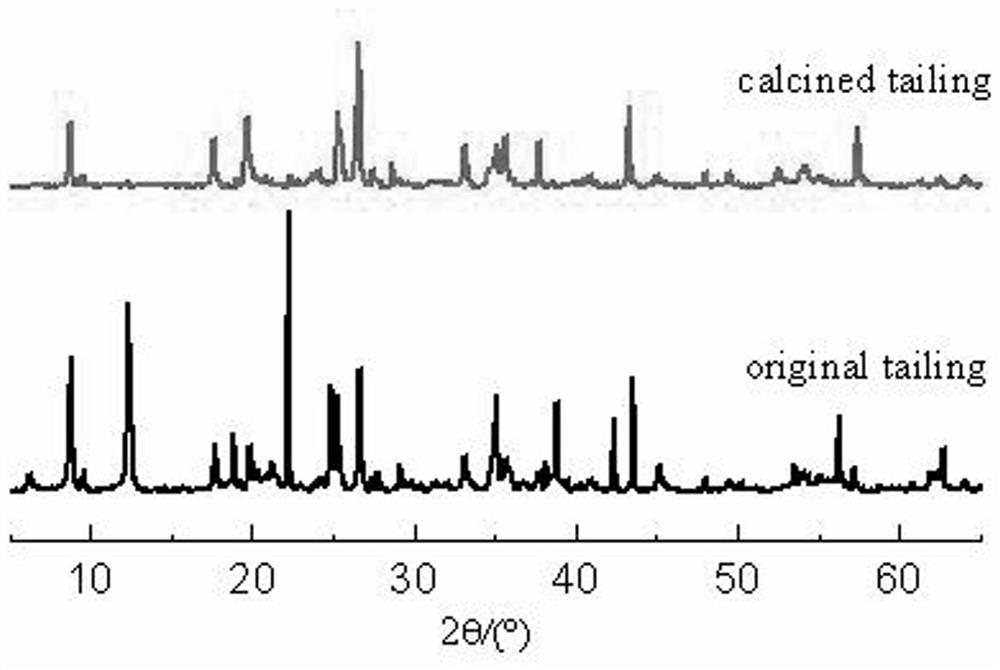

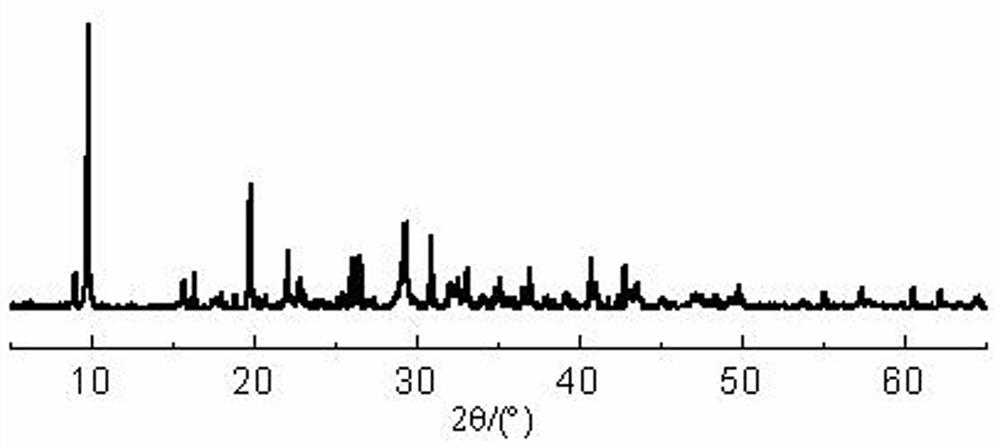

Non-autoclaved aerated concrete containing bauxite tailings and preparation method thereof

The invention provides non-autoclaved aerated concrete containing bauxite tailings and a preparation method thereof. The non-autoclaved aerated concrete is prepared by taking bauxite tailing powder, fly ash, lime, gypsum, cement, water, aluminum powder paste and an additive as raw materials. The preparation method comprises the following steps: converting non-active minerals into high-activity aluminum oxide and silicon oxide by adopting the high-temperature-treated bauxite tailings; then generating a new product by aluminum oxide and silicon oxide under a non-autoclaved condition, wherein thenew product can exist stably so that the specific strength of the aerated concrete is improved. The invention provides a novel bauxite tailing comprehensive utilization manner; recycling of industrial solid wastes can be realized so that the non-autoclaved aerated concrete has profound environment protection meaning and social benefits.

Owner:HENAN POLYTECHNIC UNIV

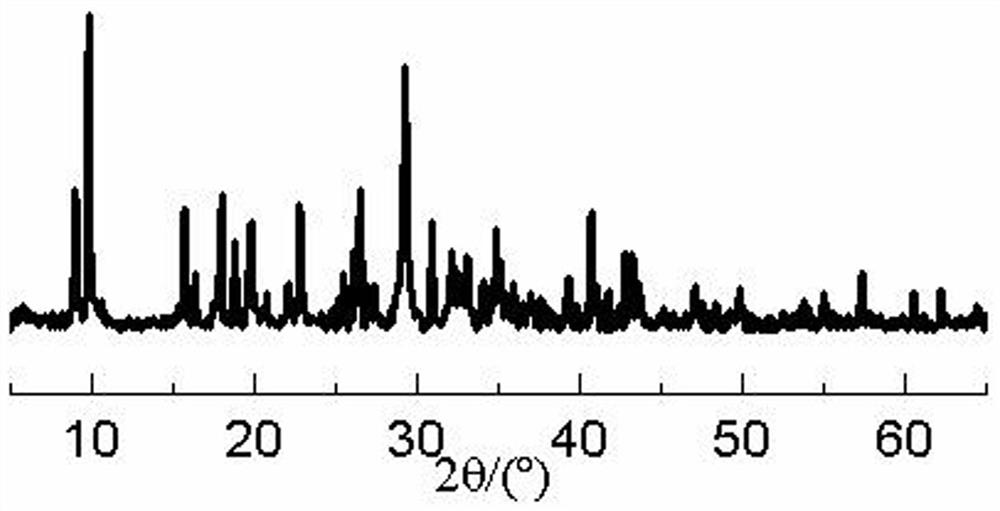

Method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue

ActiveCN102659559BScientific and rational useSimple recycling processCarboxylic acid salt preparationOXALIC ACID DIHYDRATEHydrogen fluoride

The invention relates to the technical field of material preparation, in particular to a method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue. The method comprises the following steps: reacting to leach the recovered rare earth polishing powder waste residue in concentrated sulfuric acid to obtain a lanthanum cerium sulfate solution; separating the lanthanum cerium sulfate solution from solid residue, and adding oxalic acid to obtain a lanthanum cerium oxalate precipitate; and filtering and separating the lanthanum cerium oxalate precipitate, washing to neutrality, and drying to obtain the finished lanthanum cerium oxalate product. Fluorides such as hydrogen fluoride are not required, the polishing powder waste residue is scientifically and reasonably utilized comprehensively, and the whole recovery process is environment-friendly. The method has the characteristics of small investment, low recovery cost, simple process flow, high recovery rate, environment friendliness and the like.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

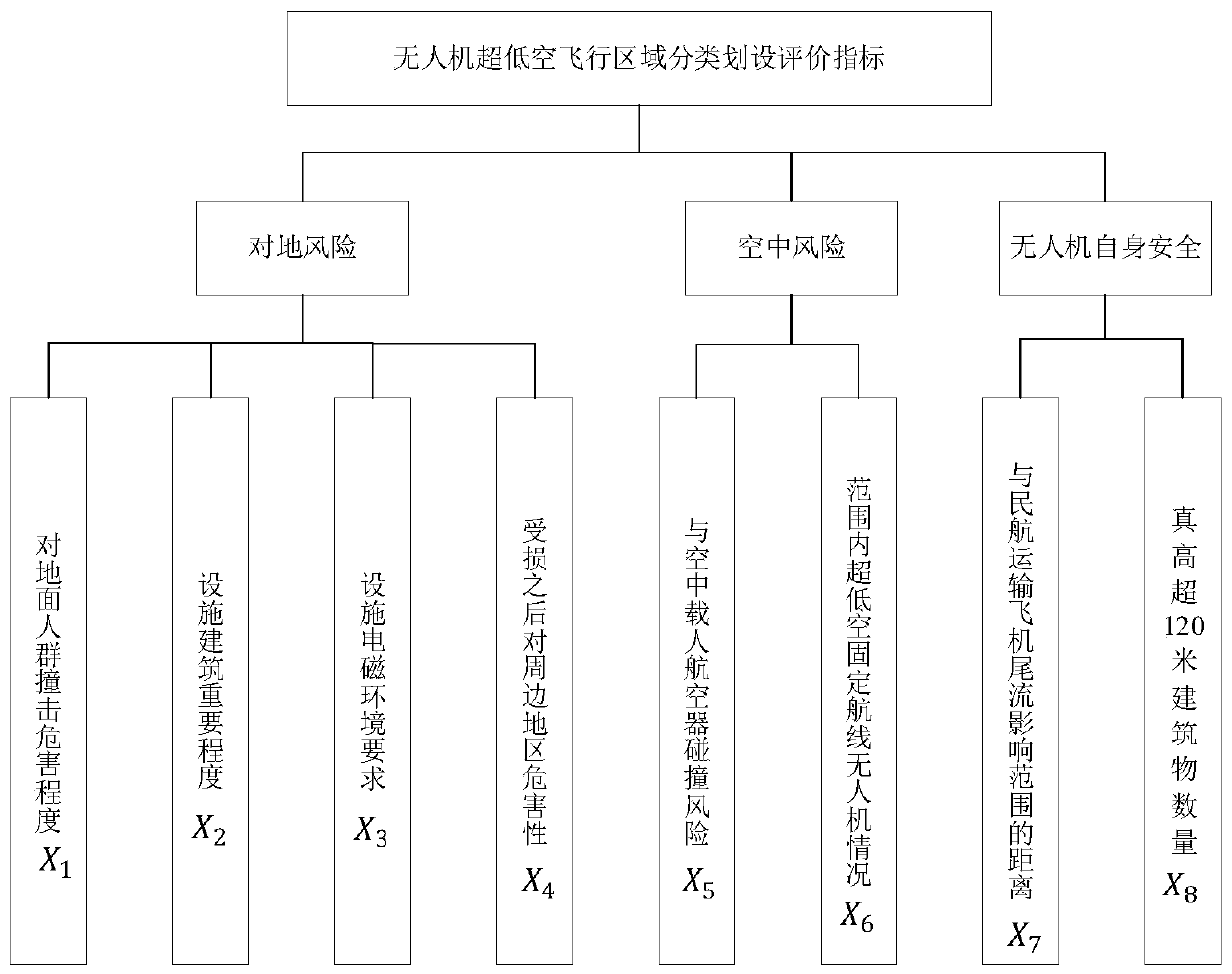

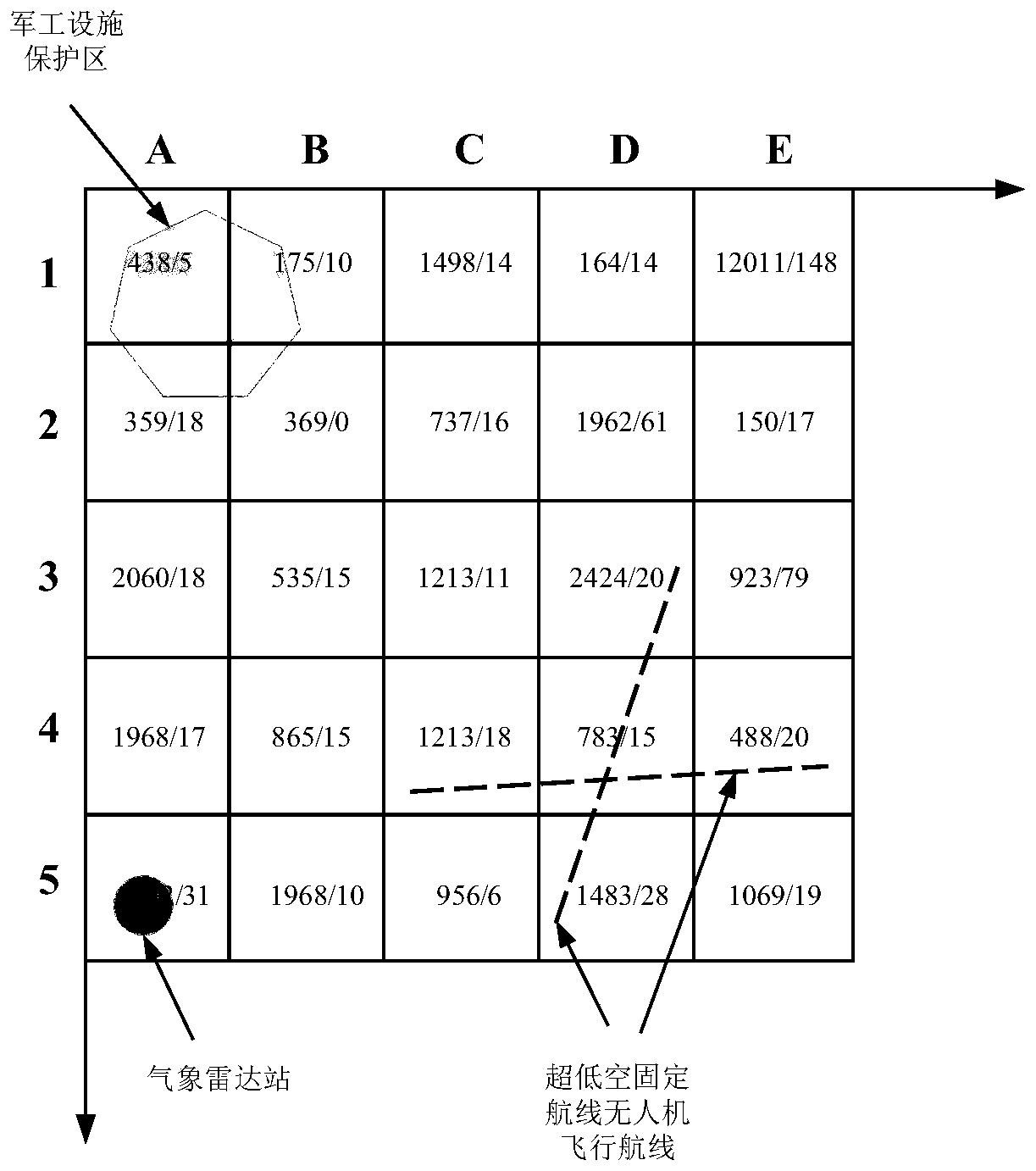

Ultra-low-altitude flight area classification setting method for unmanned aerial vehicle

ActiveCN111506974ACompatible with actual application scenariosMeet operational needsGeometric CADCharacter and pattern recognitionRisk levelSimulation

The invention discloses an ultra-low-altitude flight area classification setting method for an unmanned aerial vehicle, and the method comprises the following steps: carrying out the rasterization ofthe ultra-low-altitude flight area, and carrying out the unique identification of each grid; establishing unmanned aerial vehicle ultra-low-altitude flight area classification setting evaluation indexes and index quantitative calculation models to obtain n evaluation indexes and c risk level value intervals corresponding to the n evaluation indexes respectively; utilizing a G1 method to obtain each index weight; determining an adjacent grid addition characteristic value according to the risk evaluation index value interval corresponding to each grid; calculating the grade relative membership degree of the indexes corresponding to the grids; calculating to obtain an unmanned aerial vehicle flight limitation degree level characteristic value corresponding to the grid; and establishing an unmanned aerial vehicle flight limit degree level characteristic value threshold value model, comparing the unmanned aerial vehicle flight limit degree level characteristic value corresponding to the grid with the unmanned aerial vehicle flight limit degree level characteristic value threshold value, and determining an unmanned aerial vehicle ultra-low-altitude flight area classification division level number corresponding to the grid. The unmanned aerial vehicle ultra-low-altitude flight area classification setting method based on quantitative analysis is established by comprehensively considering three factors of the unmanned aerial vehicle over-the-ground risk, the over-the-air risk and the operation safety of the unmanned aerial vehicle.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

Making process of composite beef granules rich in collagen components

InactiveCN111543596AEasy to beEasy to digest and absorbFood shapingGranule ProductProcess engineering

The invention discloses a making process of composite beef granules rich in collagen components. The making process comprises the following steps of curing bovine lungs, curing beef, performing extrusion, performing die compaction, performing dicing, performing drying and performing aftertreatment. The whole steps do not need extraction treatment, collagen in the bovine lungs is directly utilized,the utilization rate is higher, unnecessary procedures are reduced, and bovine lung resources are scientifically and reasonably utilized. The cured bovine lungs and beef are subjected to extrusion treatment to obtain tissue components with new structures, so that subsequently developed composite beef granule products have excellent collagen digestion and absorption effects. Meanwhile, according to the beef granules prepared by the method, collagen is easier to digest and absorb, and through verification of a three-stage digestion and absorption model, the absorption rate is increased by 12%-22% in terms of the content of hydroxyproline, the slag breaking rate is also reduced, and the slag breaking rate of a finished product of the composite beef granules is reduced by 4%-7%. The method has the advantages of simple process, high material utilization rate and high nutritional value of the product.

Owner:安徽老炊食品有限公司

Preparation technology of methanol-to-hydrocarbon combustion gas for urban pipelines

InactiveCN104804786AReduce energy consumptionTake advantage ofGaseous fuelsPtru catalystProcess engineering

The invention discloses a preparation technology of methanol-to-hydrocarbon combustion gas for urban pipelines, and relates to the technical filed of application methods of a methanol substituent fuel. The technology comprises the following steps: preheating methanol, carrying out heat exchange to gasify methanol, introducing the gasified methanol into a superheater, heating, and carrying out a catalysis reaction on the heated gasified methanol under the catalysis of a catalyst to generate C1-C5 component-containing hydrocarbon combustion gas. The hydrocarbon combustion gas can be introduced into the urban pipelines and can be used by people. The technology converting methanol into the hydrocarbon combustion gas has good economic benefit, and improves the calorific value of the raw material methanol to 28372KJ / KG from 20083KJ / KG, so the calorific value increases by 41.27%; and the caloric power of CH of methanol is completely released, energy consumption in the methanol conversion process is small, and reaction heat heats the raw material through the heat exchanger and is fully utilized, so the energy saving benefit is high.

Owner:李卫教

Tooth-shaped multi-pole-point transom-connecting projection welding method for cable ladder

ActiveCN108817722AScientific and rational useReduce consumptionWelding/cutting auxillary devicesAuxillary welding devicesPower flowCurrent channel

The invention relates to a tooth-shaped multi-pole-point transom-connecting projection welding method for a cable ladder. The tooth-shaped multi-pole-point transom-connecting projection welding methodcomprises the steps that the ends of workpieces with the connected end faces are manufactured to be in tooth shapes, the tooth shapes of the ends of the workpieces serves as protruding points duringwelding, the workpieces with the protruding points are clamped up and down by tool clamps, plane workpieces are aligned with the protruding point workpieces and fixed and clamped by tool clamps, the clamps for the two parts of workpieces are all provided with conductive blocks, and the conductive blocks are closely attached to welded workpieces with connected transoms to form a current channel required by welding; and a plurality welding stations can be arranged in the length direction of the cable ladder for simultaneous welding, the welded positions of the plane workpieces are compressed bythe workpieces with the tooth-shaped protruding points during welding, the current is input while compressing is conducted, under the action of the large current, the conductive contact faces of the tooth-shaped protruding points are small, the resistance is increased instantly, and thus the positions, making contact with the plane, of the workpiece protruding points generate an overheating reaction to form a point-like continuous welded face.

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

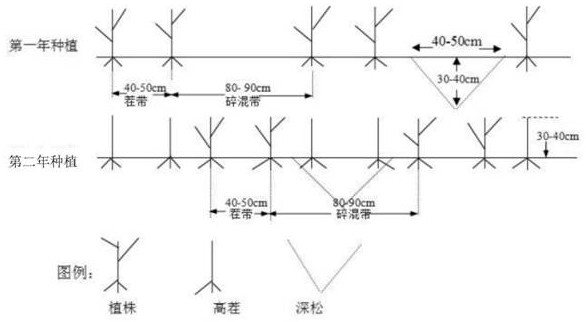

Corn tillage and cultivation method for northeast China

PendingCN111937694AIncrease organic matterIncrease organic materialCereal cultivationSoil scienceSoil organic matter

The invention provides a corn tillage and cultivation method for northeast China, and relates to the technical field of crop cultivation. According to the method, through straw full-amount returning,a wide-width crushing and mixing technology is adopted, soil organic materials are added, the soil organic matter content is increased, soil is fertilized, the tilling property of soil is improved, the black land is scientifically and reasonably utilized, and the black land is protected. The scientific and technological means and technology are applied, starting from improvement of the agricultural resource environment, the problem about black land protection is solved, the black land quality is improved, the land production capacity is improved, agricultural resources are sustainably utilized, the virtuous circle of planting industry production is achieved, and the agriculture of the black land of northeast China is promoted to be developed to the direction of sustainability and high efficiency. Corn wide-narrow row convention planting is adopted, and the problems that during spring sowing, the soil water content is low, the soil moisture content is poor, and the seedling protection rate is low are mainly solved.

Owner:JILIN ACAD OF AGRI SCI

Preparation method of fish skin collagen peptide

InactiveCN112899335ASolve problems such as waste of resourcesSolve problems such as wasteConnective tissue peptidesPeptide preparation methodsHydrolysateCollagenan

The invention provides a preparation method of fish skin collagen peptide, and belongs to the technical field of marine collagen peptide preparation. The preparation method comprises the following steps of: sequentially soaking fish skin in an alkaline solution and an acid solution for pretreatment, then performing water extraction, and transferring effective components in the fish skin into a leaching solution to obtain a gelatin leaching solution; performing enzymolysis on the gelatin leaching solution, and effectively performing enzymolysis on macromolecular protein into peptide substances to obtain an enzymatic hydrolysate; filtering to remove raw material residues and suspended matters in the enzymatic hydrolysate; performing ultrafiltration on an enzymatic hydrolysate filtrate to separate collagen peptide with the molecular weight of 7000-8000Da; and decolorizing an ultrafiltrate, then performing nanofiltration desalination, and intercepting collagen peptide with the molecular weight of 200-1000Da to obtain the fish skin collagen peptide. According to the preparation method provided by the invention, impurities with different molecular sizes are removed step by step in multiple links, so that the impurities in the collagen peptide can be effectively reduced.

Owner:德兰梅勒(北京)分离技术有限公司

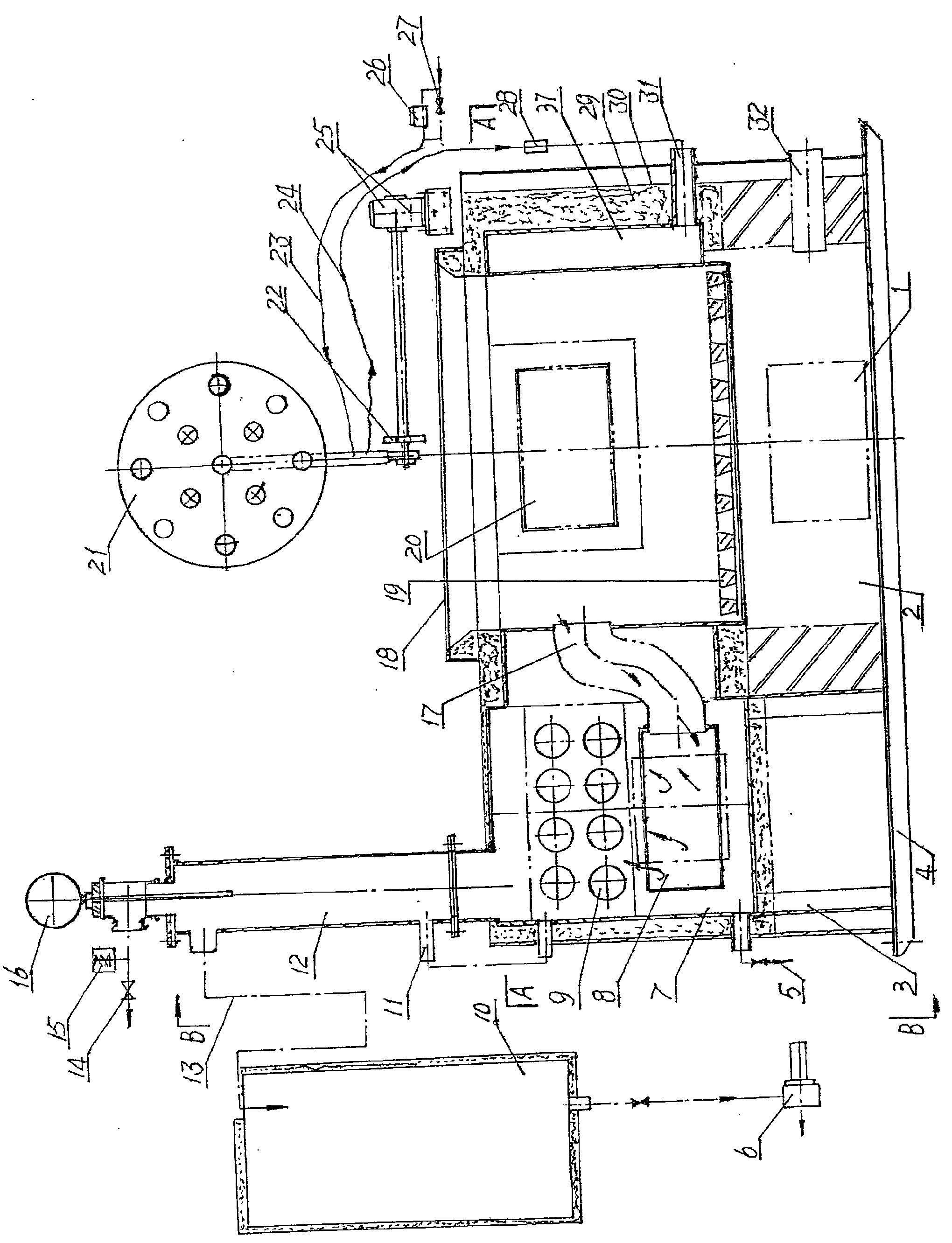

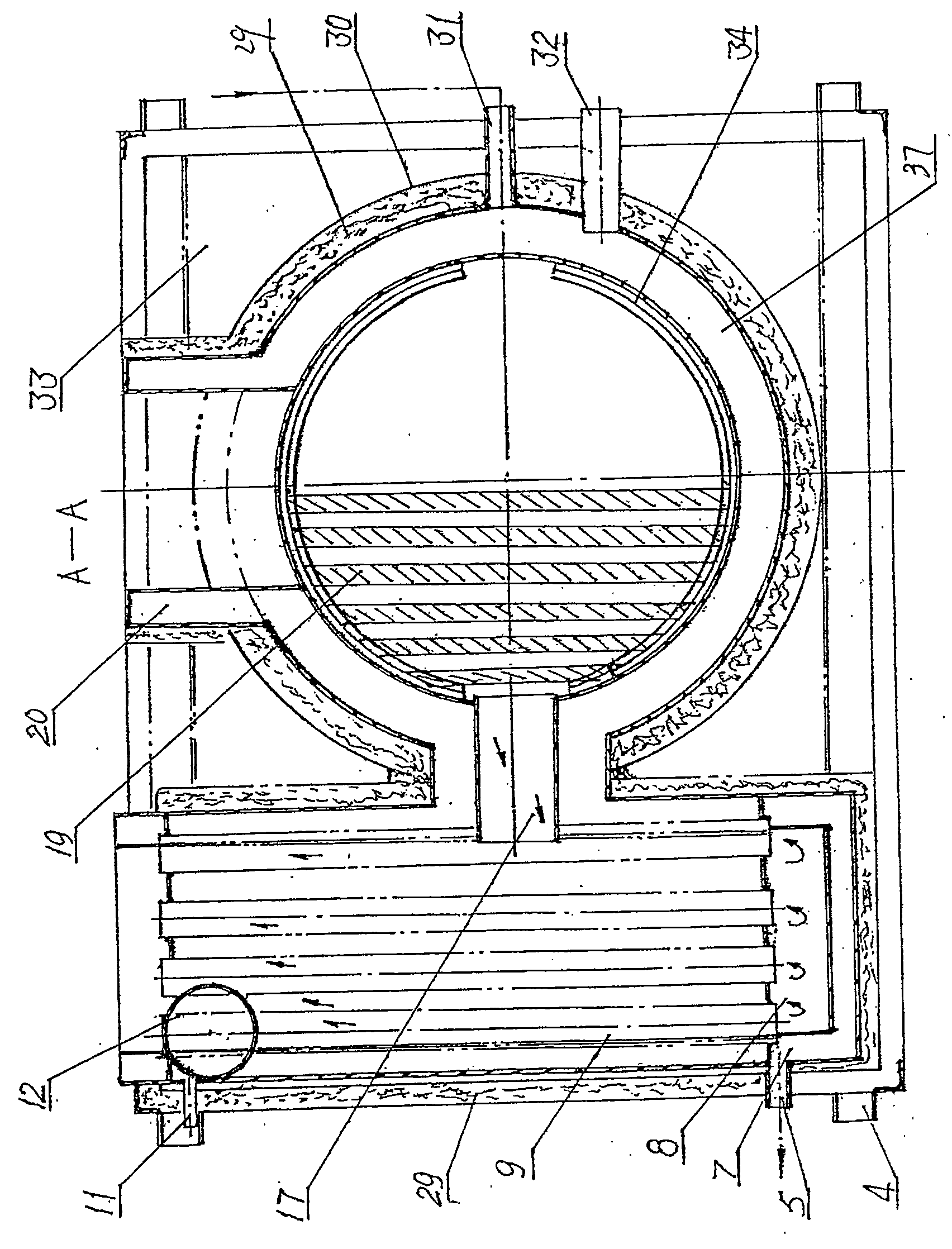

High efficiency multi-functional energy-saving range

ActiveCN100549531CScientific and rational useReduce pollutionDrum steam boilersStove/ranges for heating waterEngineeringExhaust pipe

A high-efficiency multifunctional energy-saving stove, belonging to stoves, has a dust-cleaning sealed door (1), a fuel-delivery sealed door (20), a stove ring (18) on the top, a main water bag (37) around it, and an inlet The water pipe (31) and the tuyere (32), the stove body are connected with the flue gas lower flue chamber (8) and the rear flue chamber (43) below the flue gas heat utilization pot (7) through the flue gas exhaust pipe (17), and through The waste heat is connected with the front smoke chamber (41) with the fire pipe (9), and there are a water outlet pipe (12) and a chimney (40) above the flue gas utilization pot (7), and a steam valve (14) is installed on the water outlet pipe. The micro-pressure safety valve (15), the water level gauge (11) and the electric contact thermometer (16) are connected to the heat preservation water tank (10) through the U-shaped outlet water seal safety pipe (13). Fuel heating can be used for frying, boiling, and steaming various foods, and it can also provide clean and hygienic boiling water and hot water. When the stove is resting after cooking, the coil heat exchanger can be used to absorb 70~ 80% heat, more boiled water and hot water can be obtained, and the invention can ensure safe, economical and energy-saving operation.

Owner:李福成

Quartz sand purification system without washing procedure

ActiveCN112678830ALow processing and running costsAvoid clumpingSilicaDrying solid materials with heatFluidized bed dryingWater use

The present invention discloses a quartz sand purification system without the washing procedure. The quartz sand purification system without the washing procedure comprises an acid pickling device, a filtering device, a drying device and a finish machining device, and quartz sand materials are sequentially transferred among the acid pickling device, the filtering device, the drying device and the finish machining device; the drying device comprises a fluidized bed dryer, a material inlet of the fluidized bed dryer is connected with a stock bin, and a material outlet is connected with a collecting bin. A hot air inlet of the fluidized bed dryer is sequentially connected with a heating furnace, an air blower and an air filter, a hot air outlet is sequentially connected with a cooler, a multi-stage dust removal device, a multi-stage water absorption device and an acid mist absorption tower through pipelines, and a gas outlet of the acid mist absorption tower is communicated with the atmosphere. According to the invention, deacidification in a washing process can be satisfied, a large amount of environmental protection and production investment are saved, water and wastewater treatment operation cost is saved, production cost is reduced, and an impurity removal effect can be further achieved in a fluidized bed drying process.

Owner:龙川县明昊石英新材料有限公司 +1

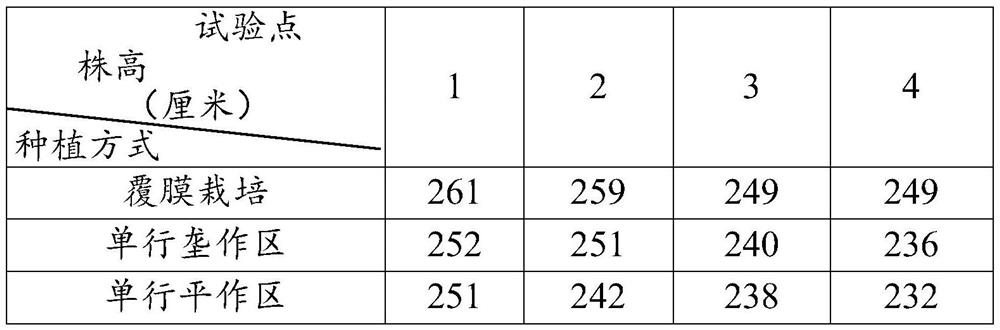

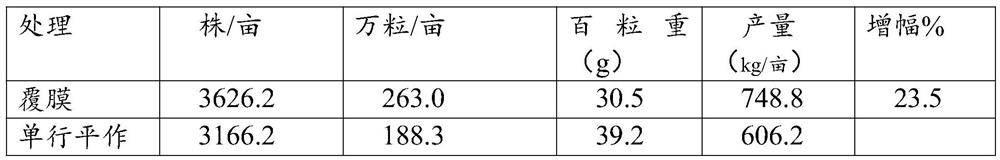

Method for cultivating corn through high-ridge film mulching

InactiveCN113133395AImprove frost resistanceEarly sowingClimate change adaptationCereal cultivationPlastic mulchRidge

The invention relates to the technical field of corn cultivation. The invention discloses a method for cultivating corn through high-ridge film mulching. The method comprises the following steps: 1) ridge culture field: the ridge height after soil preparation is 20-25 cm, and according to formed ladder-shaped ridges, the ridge bottom width is 120-130 cm, and the ridge top width is 90-100 cm; 2) film mulching: a mulching film with the breadth of 80-100cm and the thickness of 0.008 mm is selected for film mulching; and 3) mechanically sowing and fertilizing: the soil is regularly watered and irrigated, hoeing, insect killing and fertilization are carried out until the corns are mature, the corns are harvested, and therefore, the cultivation of the corns is completed. According to the method, the yield of the corns is greatly increased by changing the planting mode, shrinking ridges and increasing rows and performing film mulching planting.

Owner:JILIN ACAD OF AGRI SCI

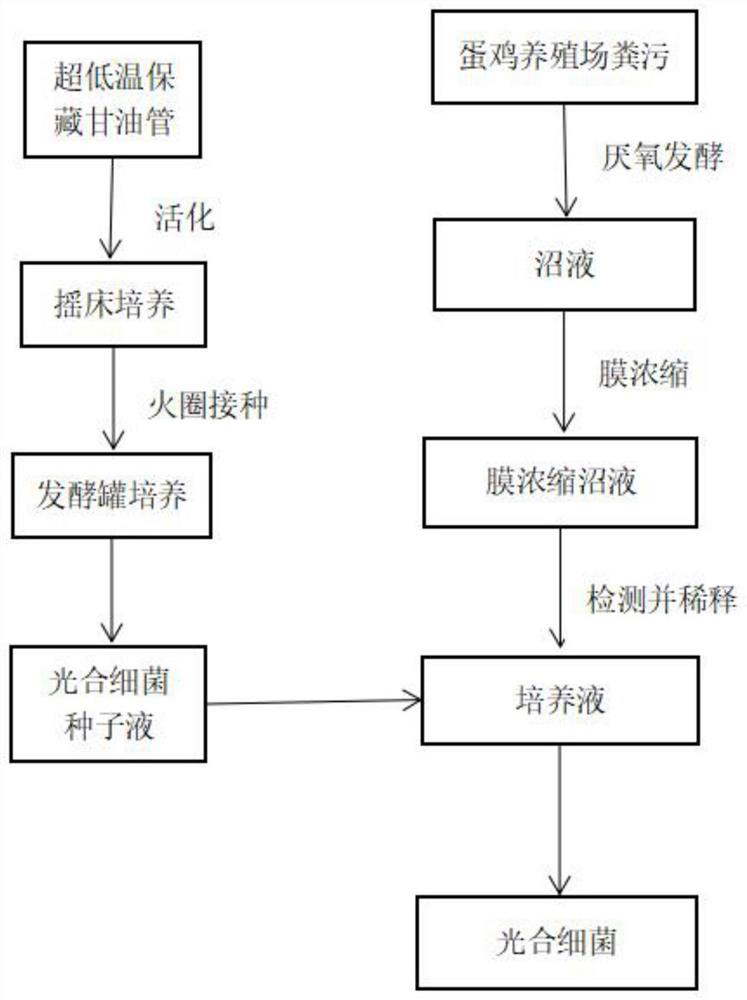

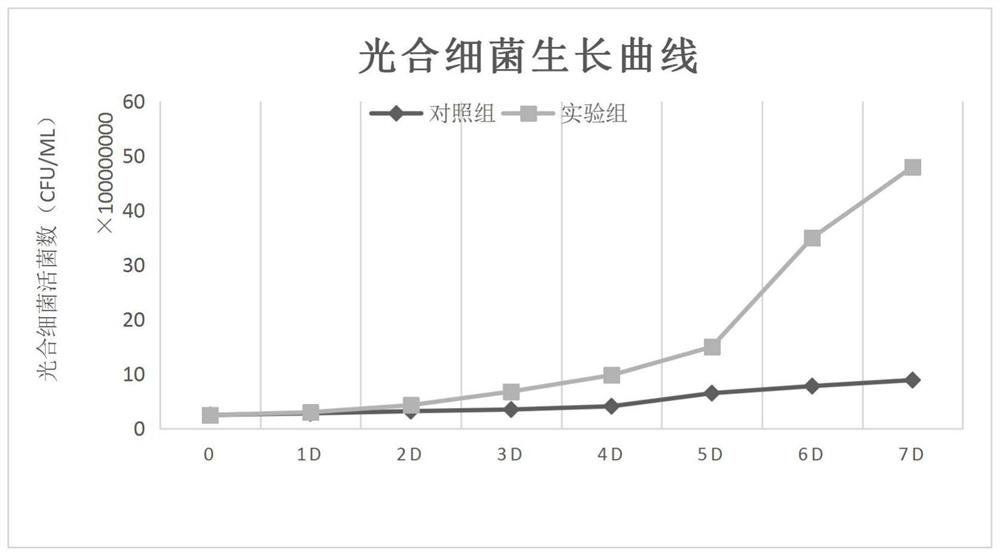

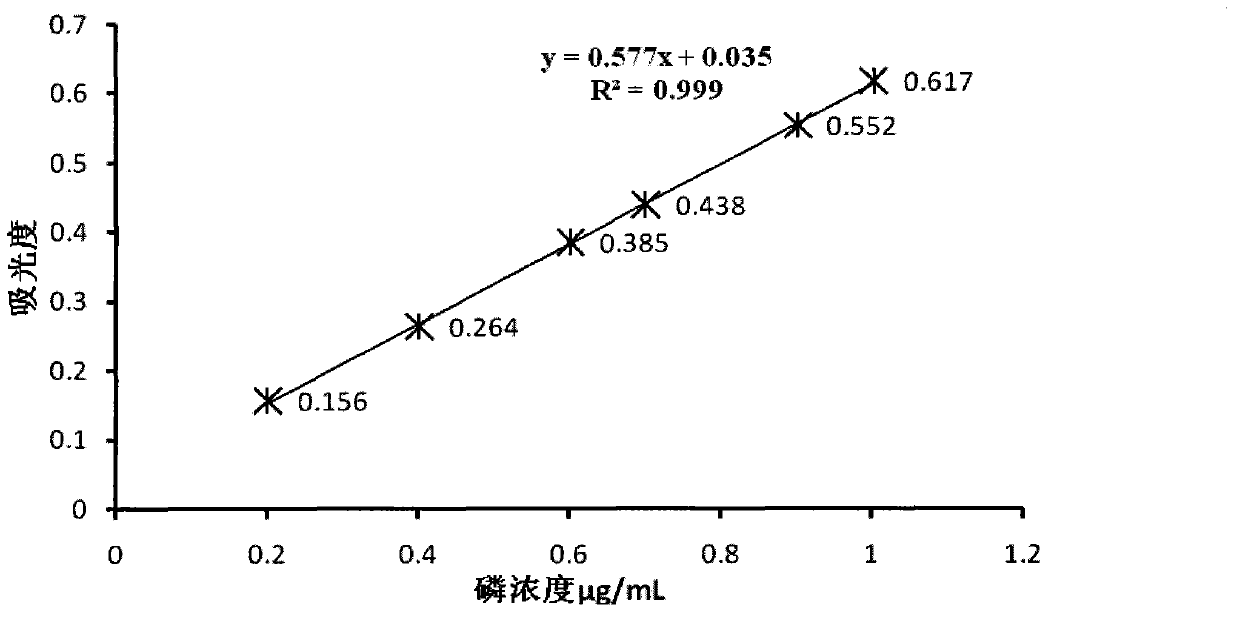

Method for culturing photosynthetic bacteria by utilizing membrane concentration biogas slurry

PendingCN112625956AShorten the culture speedLow bacteria rateBacteriaTreatment involving filtrationBiotechnologyMicroorganism

The invention discloses a method for culturing photosynthetic bacteria by using membrane concentrated biogas slurry. The method comprises the following steps: detecting the content and pH value of nitrogen, phosphorus and potassium in the membrane concentration biogas slurry, diluting the concentrated biogas slurry according to the content of nitrogen, phosphorus and potassium, directly culturing photosynthetic bacteria by using the diluted membrane concentration biogas slurry as a culture solution, controlling the inoculation amount to be 10% of the volume of the culture solution, after inoculation, performing placing under the illumination intensity of 3000-5000Lux at the temperature of 30 DEG C, and performing culturing for 5-7 days. The membrane concentration biogas slurry is adopted as a culture solution of the photosynthetic bacteria, nutrient substances are richer after the biogas slurry is concentrated, nutrient substances do not need to be manually added any more, the dilution ratio of the concentrated biogas slurry is determined by detecting various indexes such as the nitrogen, phosphorus and potassium salt degree of the concentrated biogas slurry, and it is ensured that the concentrated biogas slurry meets the growth requirement of the photosynthetic bacteria. Most of microorganisms and all solid particles in the biogas slurry subjected to membrane concentration are removed.

Owner:JIANGSU SUGANG HESHUN BIOTECH CO LTD

Stable and efficient dephosphorization composition

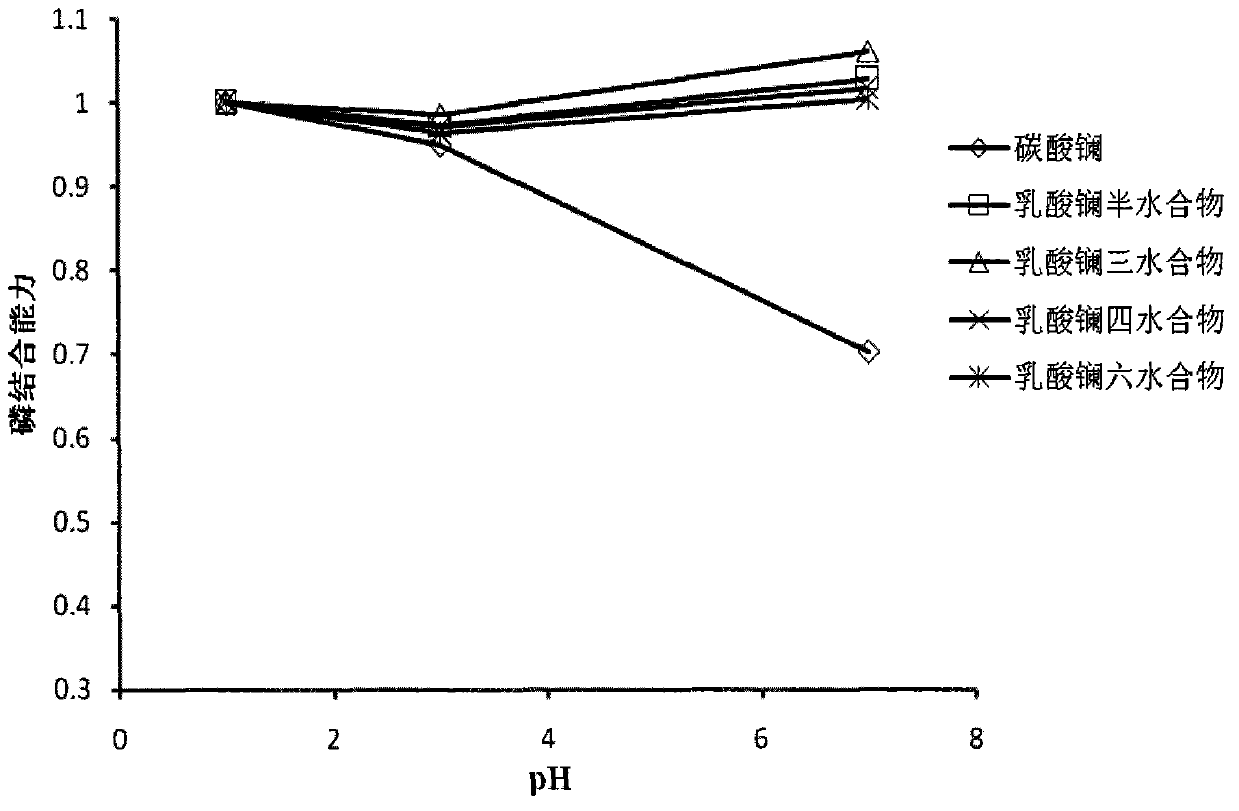

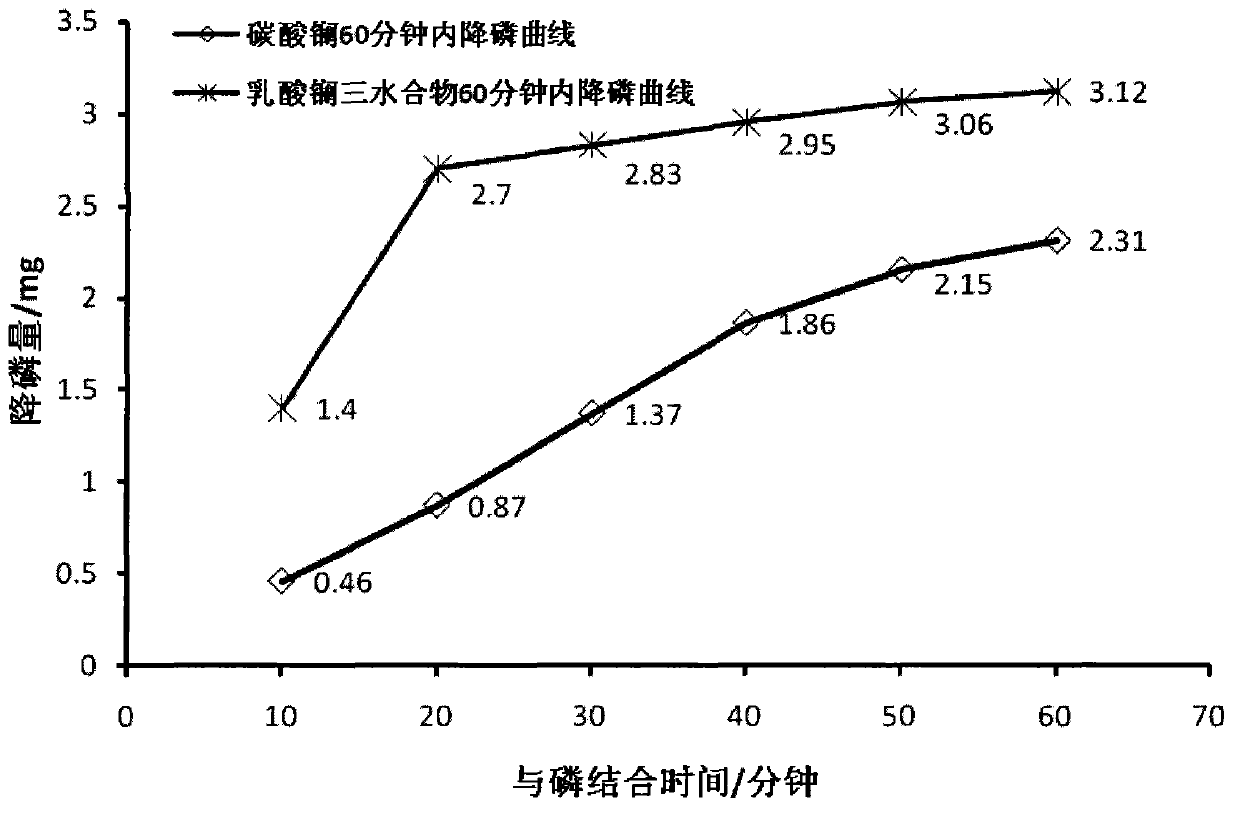

InactiveCN103127042AStrong affinityImprove comprehensive utilization efficiencyMetabolism disorderAnhydride/acid/halide active ingredientsCalcium EDTASolubility

The invention provides a stable and efficient composition for dephosphorization. The composition comprises lanthanum lactate hydrate and pharmaceutically acceptable proper auxiliary materials, wherein the average value of crystalline water in the lanthanum lactate hydrate is 0.5-6.0. The composition is applied in the form of oral administration, and the clinical daily dosage on the basis of anhydrous lanthanum lactate is 0.05-2.0g. The composition provided by the invention is free of aluminum and calcium, thereby avoiding the side effect of aluminosis, angiosteosis or the like of the patient due to taking of aluminum and calcium. The active component of the composition exists in the form of lanthanum lactate hydrate, so the solubility is high, and thus, the consistent high-level phosphorus combining capacity in vivo and in vitro can be always kept without being dependent on pH. The composition solves the problems of high consumption, high cost, poor mouthfeel and severe adverse reactions, including nausea, emesis and the like, in other lanthanum-containing dephosphorization medicines. The invention also provides a method for preparing the lanthanum lactate hydrate in the composition.

Owner:尹颖

Dead-burned magnesite shaft kiln raw material homogenization process

The invention relates to a dead-burned magnesite shaft kiln raw material homogenization process. The process comprises the steps of fine grinding, primary mixing homogenization, ball pressing, secondary mixing homogenization and sintering. Raw materials and the fuel are used. Natural high-calcium magnesite powder ore and crushed ore and natural high-silicon magnesite powder ore and crushed ore aresubjected to fine grinding and primary mixing homogenization; ball pressing is performed on a primarily mixed and homogenized material; and secondary mixing homogenization is performed on a ball pressing material and a fuel; and finally, the secondary mixing homogenization material is sintered at a temperature of 1500-1800 DEG C to prepare dead-burned magnesite. The method disclosed by the invention has the advantages of simple process flow, high product density and the like; and due to the existence of the high-melting-point forsterite phase, the high-temperature resistance and corrosion resistance of the refractory material can be improved.

Owner:海城市军刚中档镁砂有限公司

A non-autoclaved aerated concrete containing bauxite tailings and its preparation method

Owner:HENAN POLYTECHNIC UNIV

A tooth-shaped multi-pole T-connection projection welding method for cable trays

ActiveCN108890109BScientific and rational useReduce consumptionResistance welding apparatusElectrical resistance and conductanceCable tray

The invention relates to a toothed multi-pole T-type connection protrusion welding method for a cable bridge, the method comprises the following steps of: making the end part of the workpiece connected with the end face into a tooth shape, When welding, the tooth shape of the end of the workpiece is used as a bump, the workpiece with the bump is clamped up and down by the jig, the alignment of theplanar workpiece and the bump workpiece is clamped by the jig, the clamps of the two parts of the workpieces are provided with conductive blocks, and the conductive blocks and the T-shaped connectedwelded workpiece are closely fitted to form the current channel needed for welding; At least a plurality of weld stations can be arrange along that length direction of the cable tray for simultaneouswelding, When welding, the workpiece with toothed bump compresses the welded part of the planar workpiece, and the electric current is inputted at the same time. Under the action of large electric current, because the toothed bump conductive contact surface is small, the resistance increases instantaneously, and the overheating reaction occurs at the contact area between the workpiece bump and theplanar surface to form a dot-shaped continuous welding surface.

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

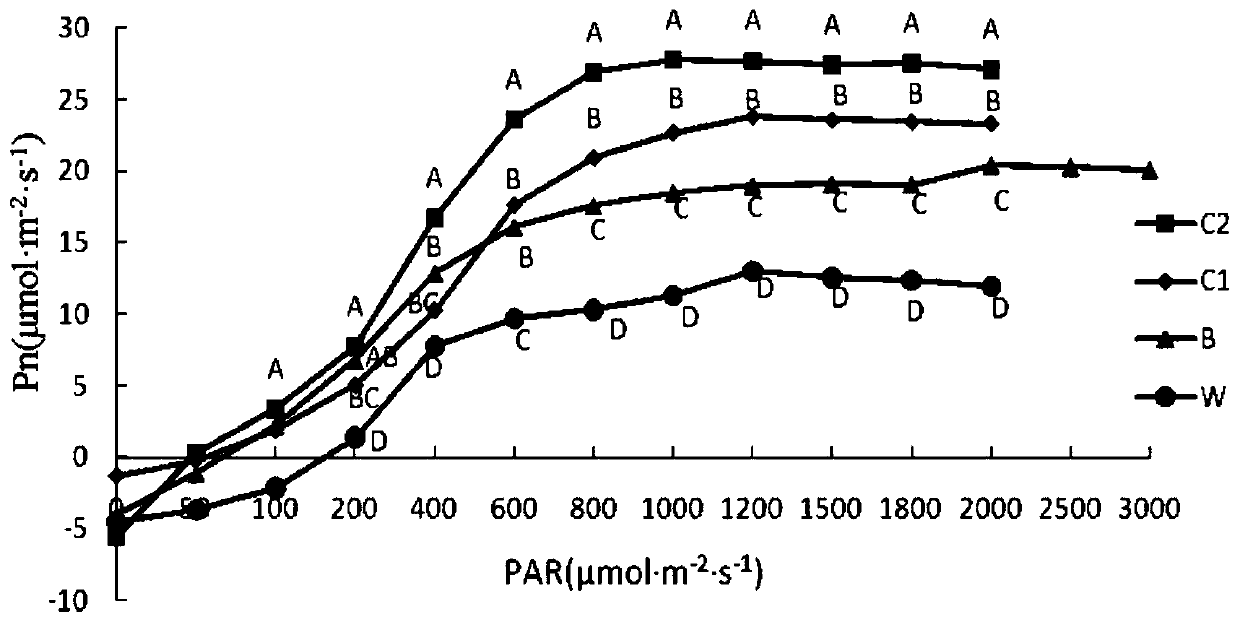

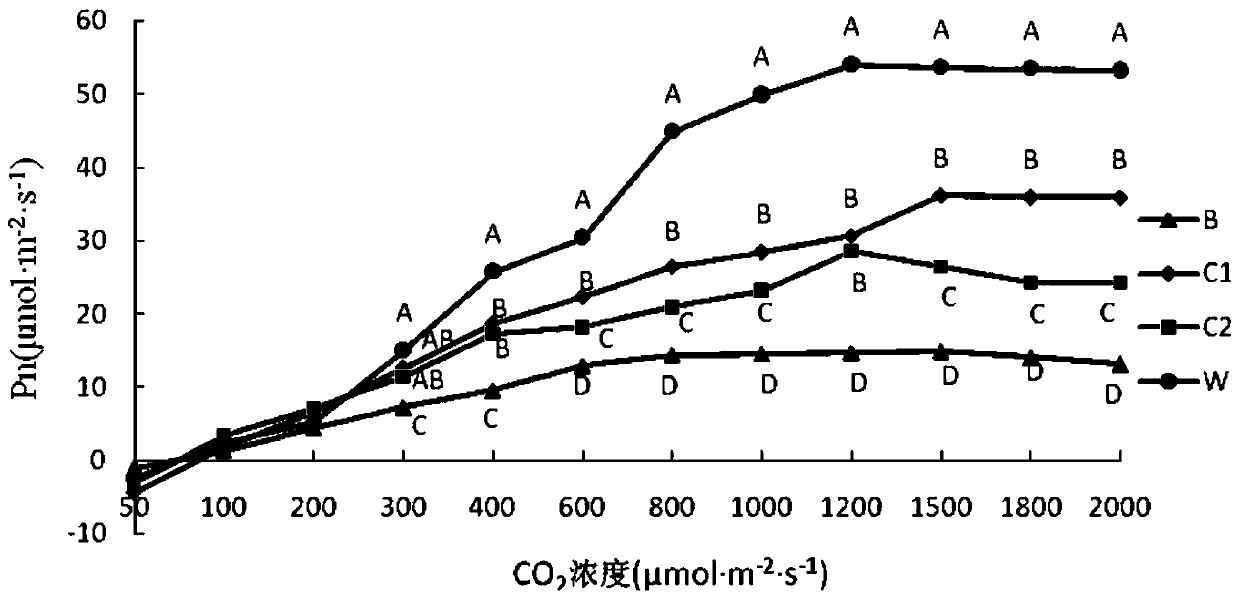

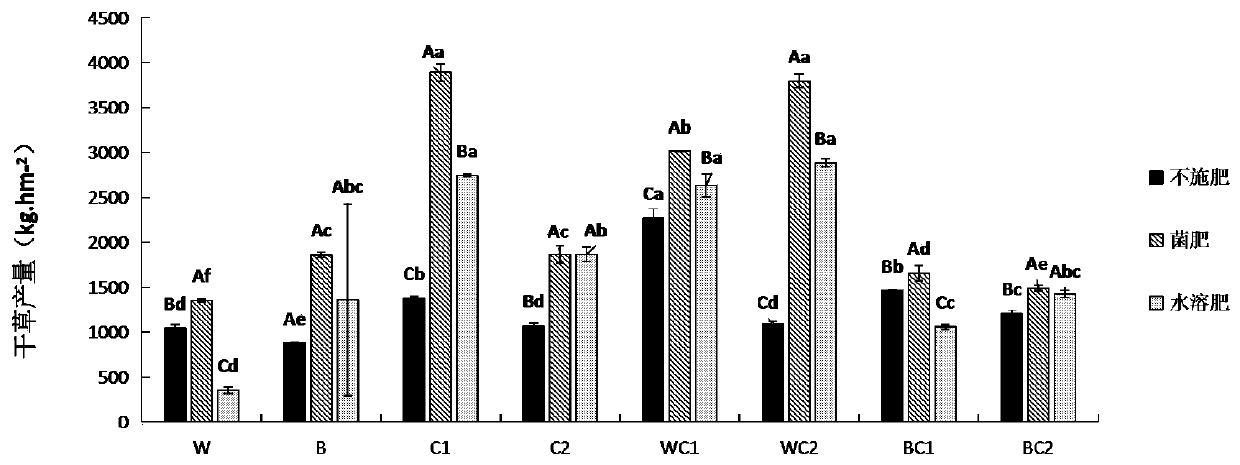

A method for establishing artificial grassland under a photovoltaic rack

ActiveCN107409682BScientific and rational useReasonable useHops/wine cultivationTurf growingEconomic benefitsGrassland

The invention discloses a method for establishing artificial grassland under a photovoltaic rack. Under the environment of a photovoltaic rack, No. 3 grassland miscellaneous alfalfa is single-sown or grassland No. 2 miscellaneous alfalfa and awnless brome are mixed; Or use microbial fertilizer when sowing mixed grassland. Through the reasonable planting of appropriate grass species and the adoption of appropriate sowing methods and fertilization types, the problems of difficulty in planting grass and low yield of pasture under photovoltaic racks are solved, and economic benefits are improved.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

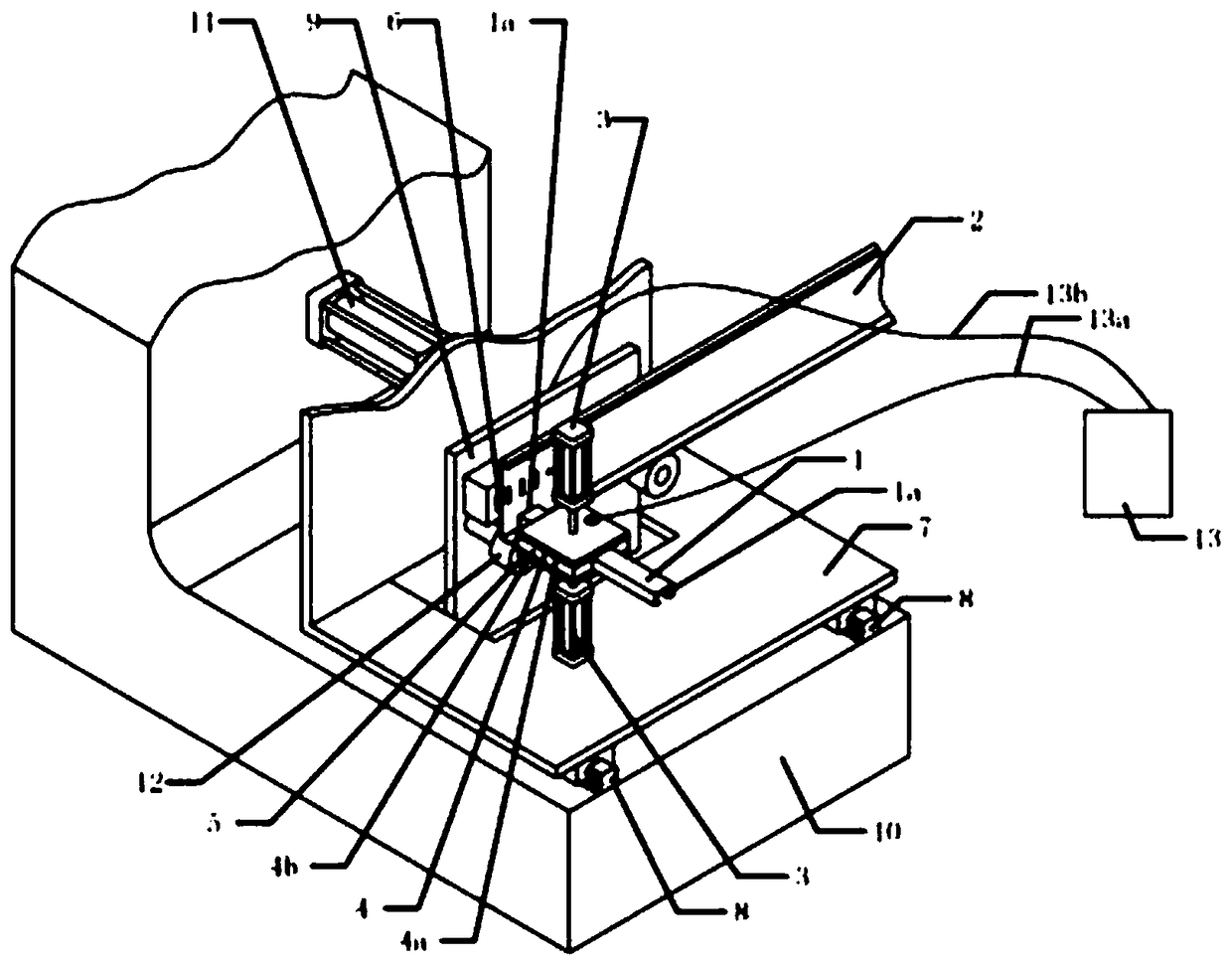

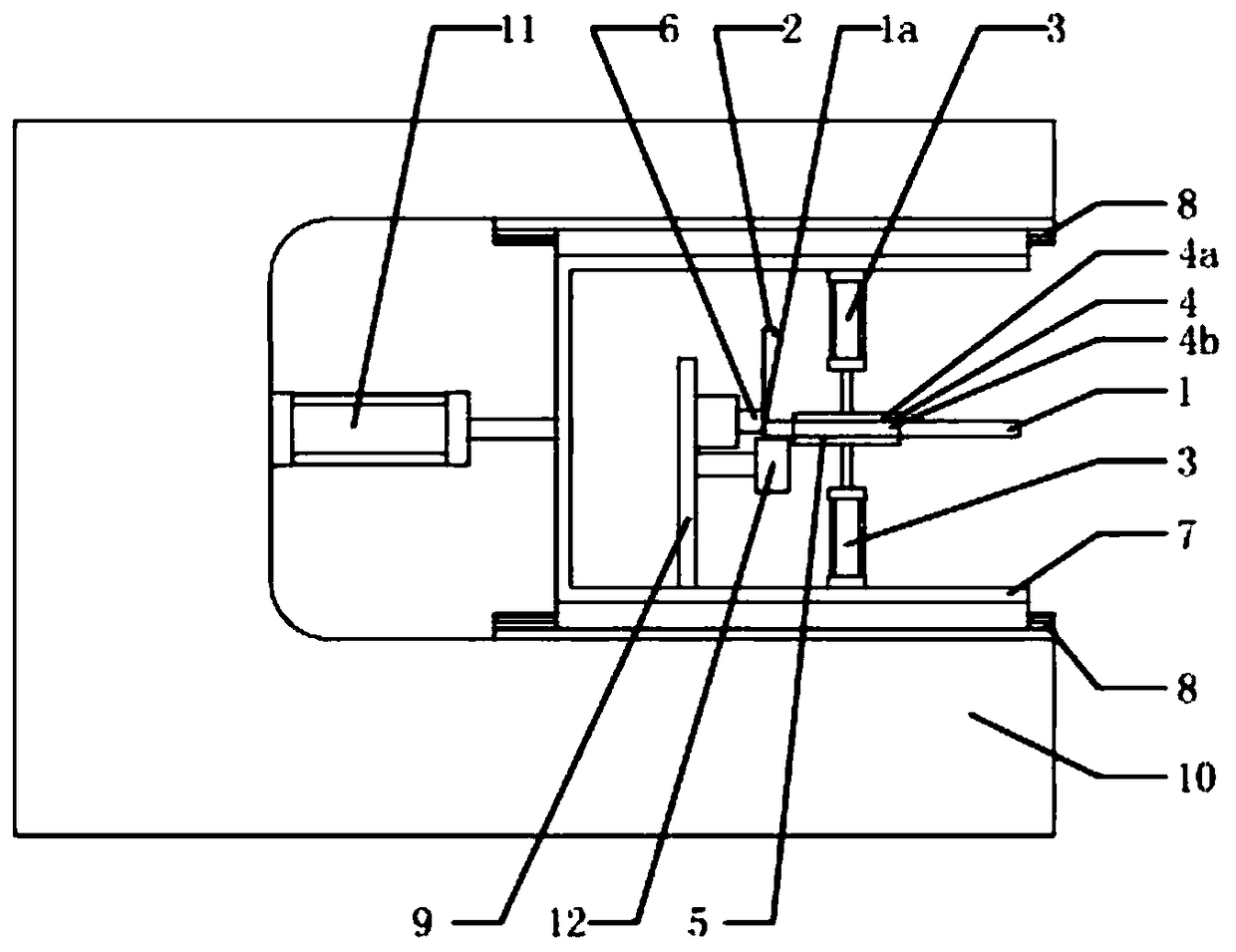

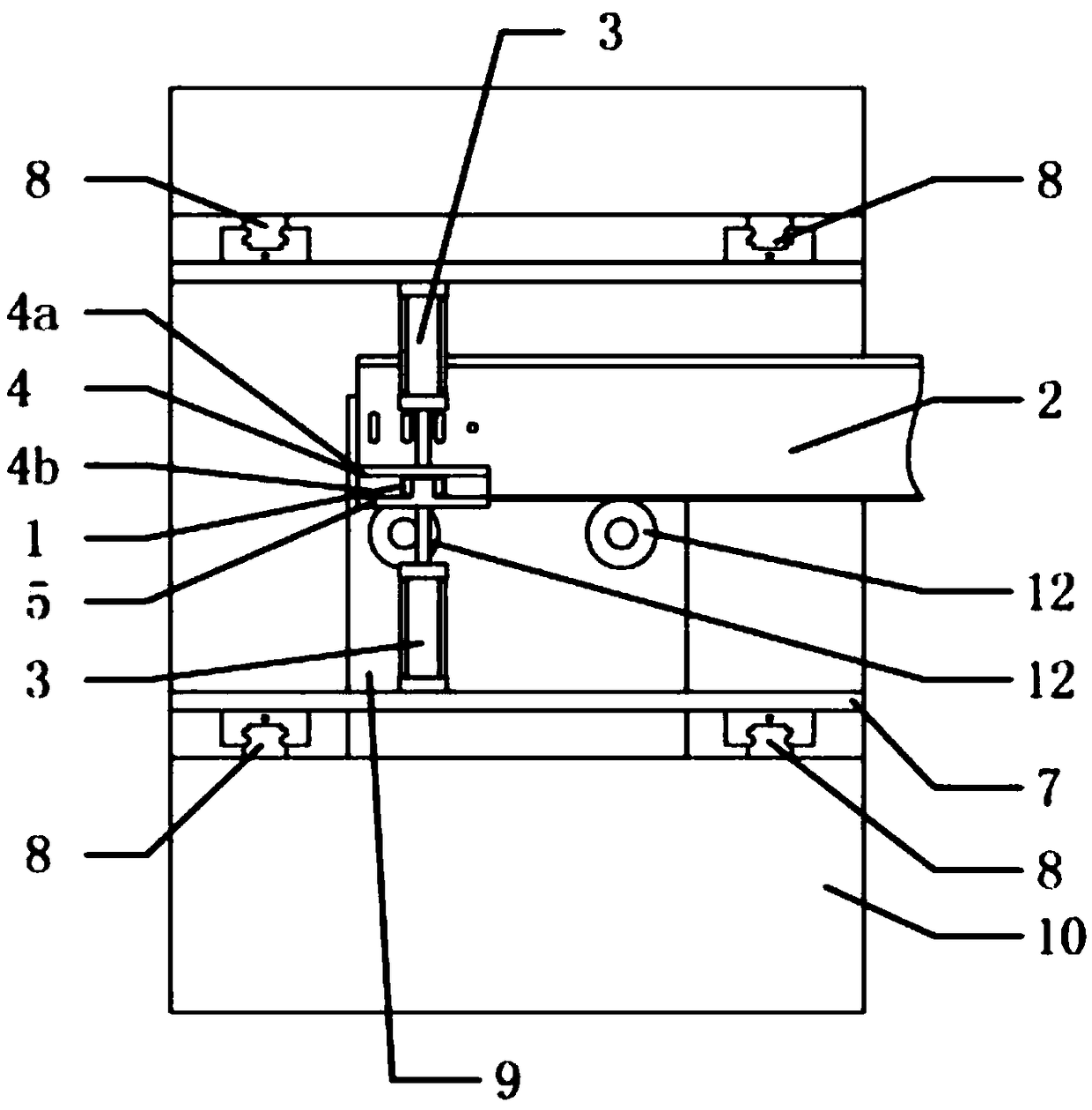

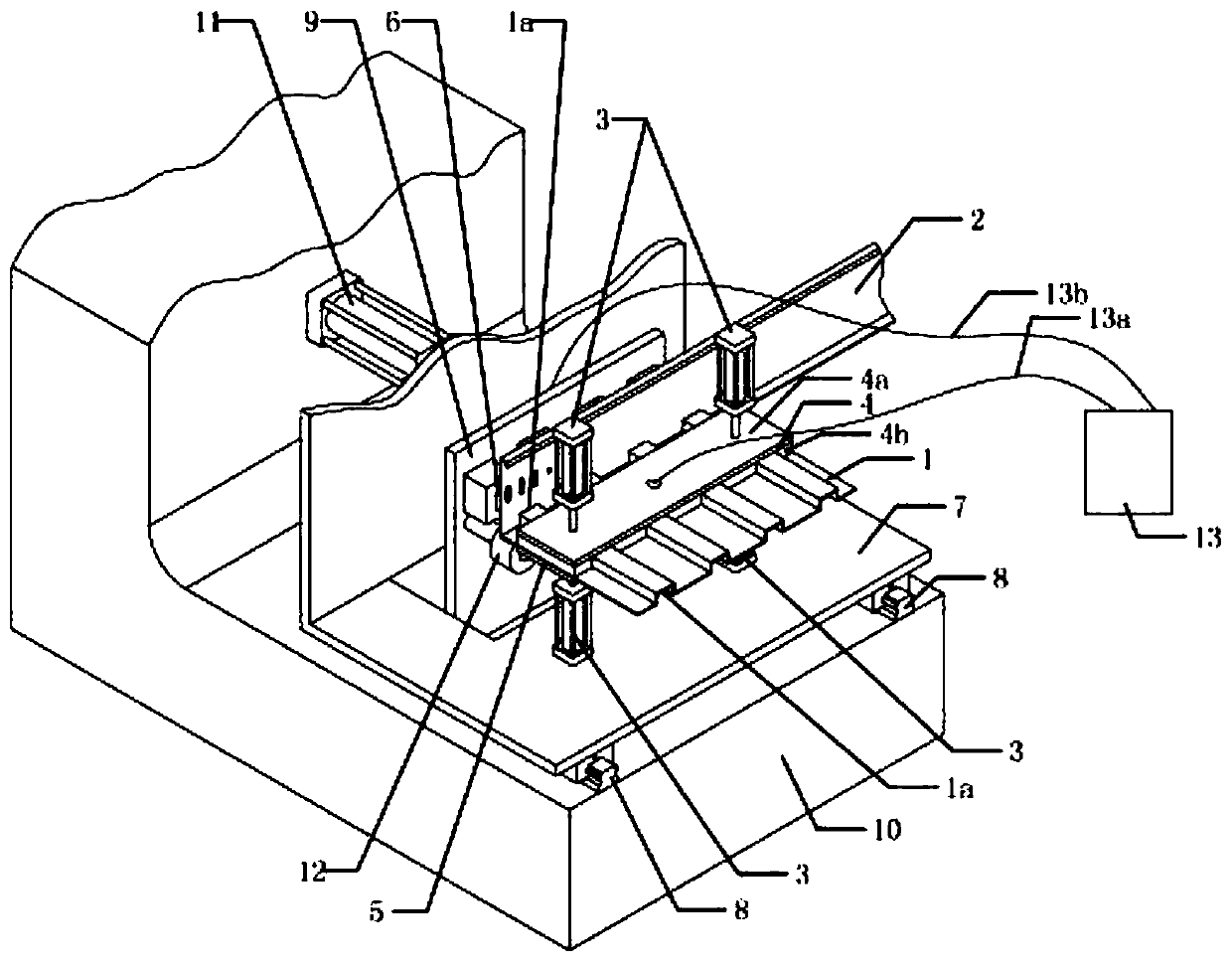

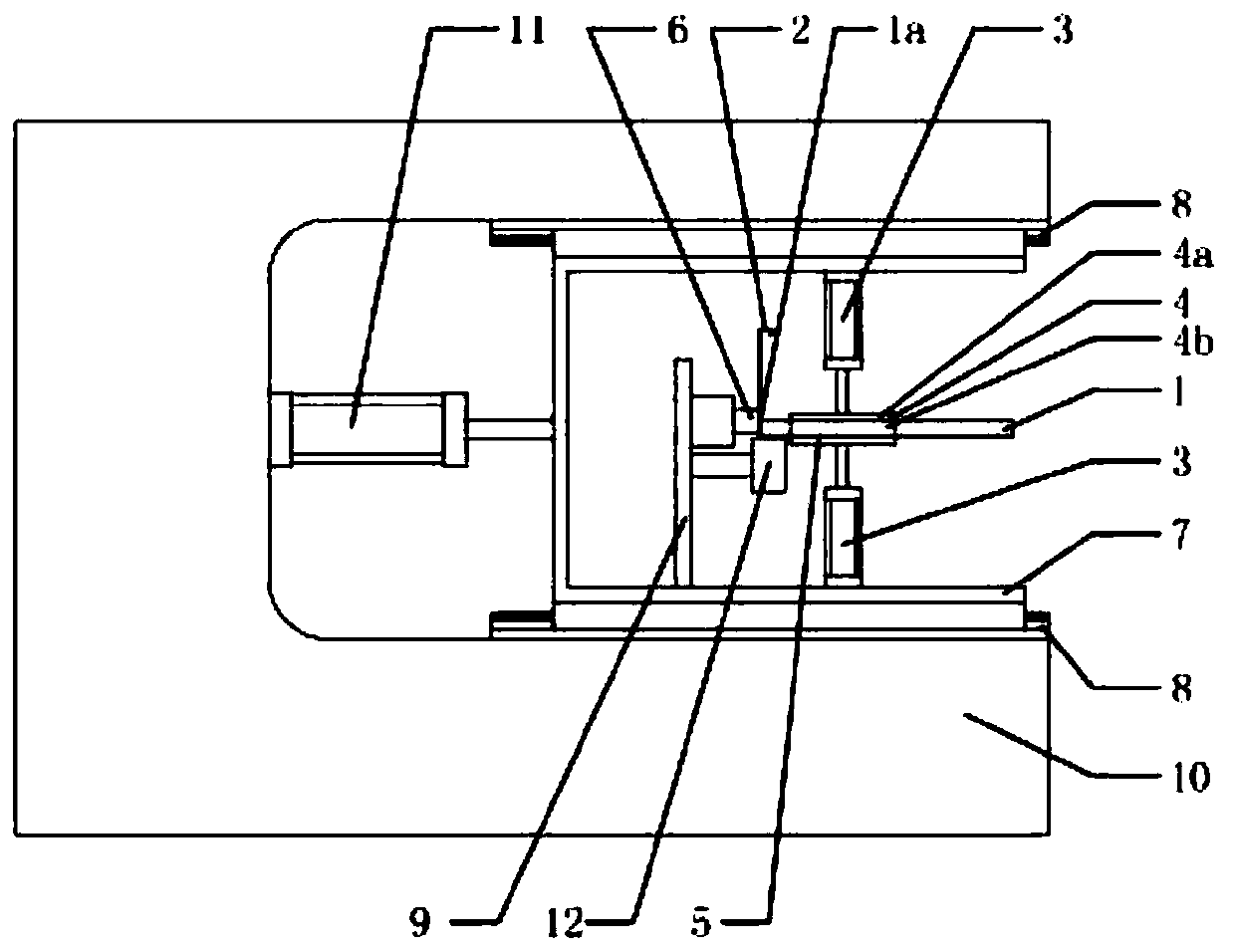

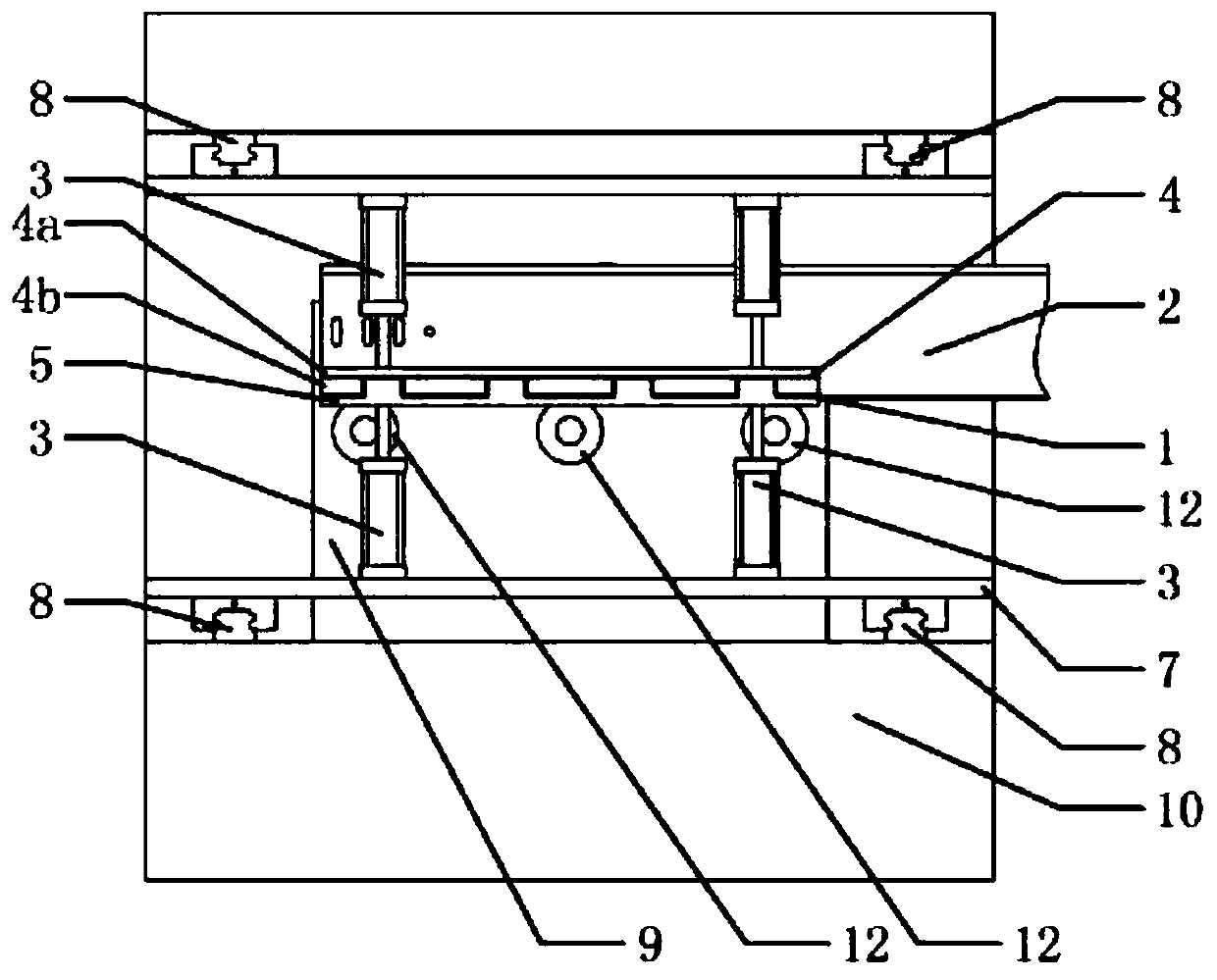

Method and device for testing ice bearing capacity

ActiveCN105547839BScientific and rational useAvoid casualtiesMaterial strength using tensile/compressive forcesEngineering researchElectrical conductor

The invention provides an ice layer bearing capacity test method and device, belongs to the field of ice engineering research, realizes the aim of scientifically and reasonably utilizing ice resources, avoids the occurrence of casualties, property loss and other serious consequences. The ice layer bearing capacity test method comprises the steps of arranging a pressure conductor at the upper surface of a tested ice layer, arranging a lower pressure distribution plate, a synchronization jack, an upper pressure distribution plate, a pressure gage and a truss above the pressure conductor in sequence, arranging a plurality of pieces of anchor rods around the pressure conductor, arranging anchor plates at the lower ends of the anchor rods to hook the lower surface of the ice layer, wherein the upper ends of the anchor rods are connected with the truss through hooks, and the sum of the contact areas of all the anchor plates with the lower surface of the ice layer is larger than the contact area of the pressure conductor and the upper surface of the ice layer, hoisting the synchronization jack to load pressure to the ice layer, and reading a value of pressure applied by the synchronization jack through the pressure gage; arranging a deflection tester at the central position of the lower pressure distribution plate, and testing the displacement of the tested ice layer; the method and the device, provided by the invention, are used for testing the ice layer bearing capacity.

Owner:程培峰

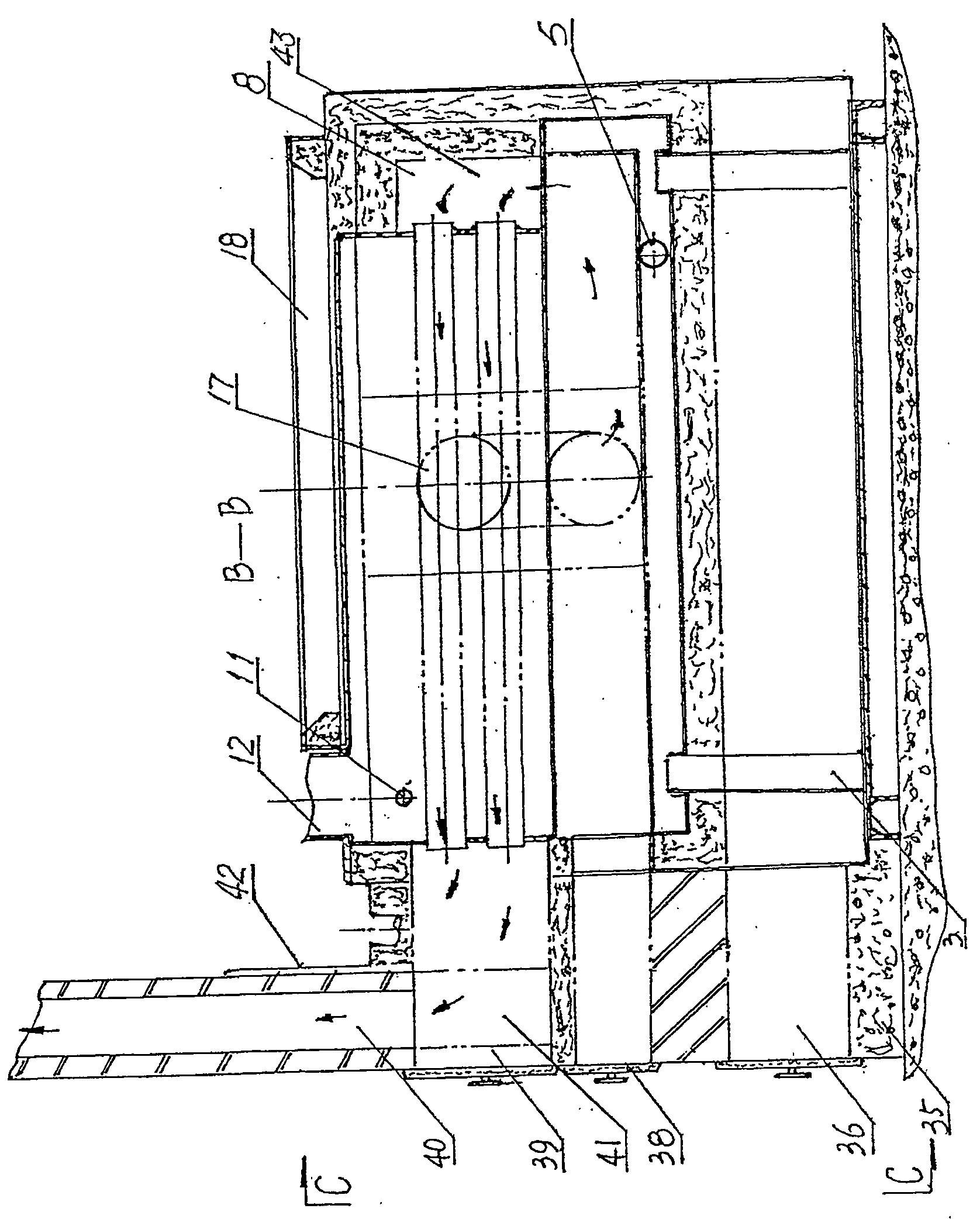

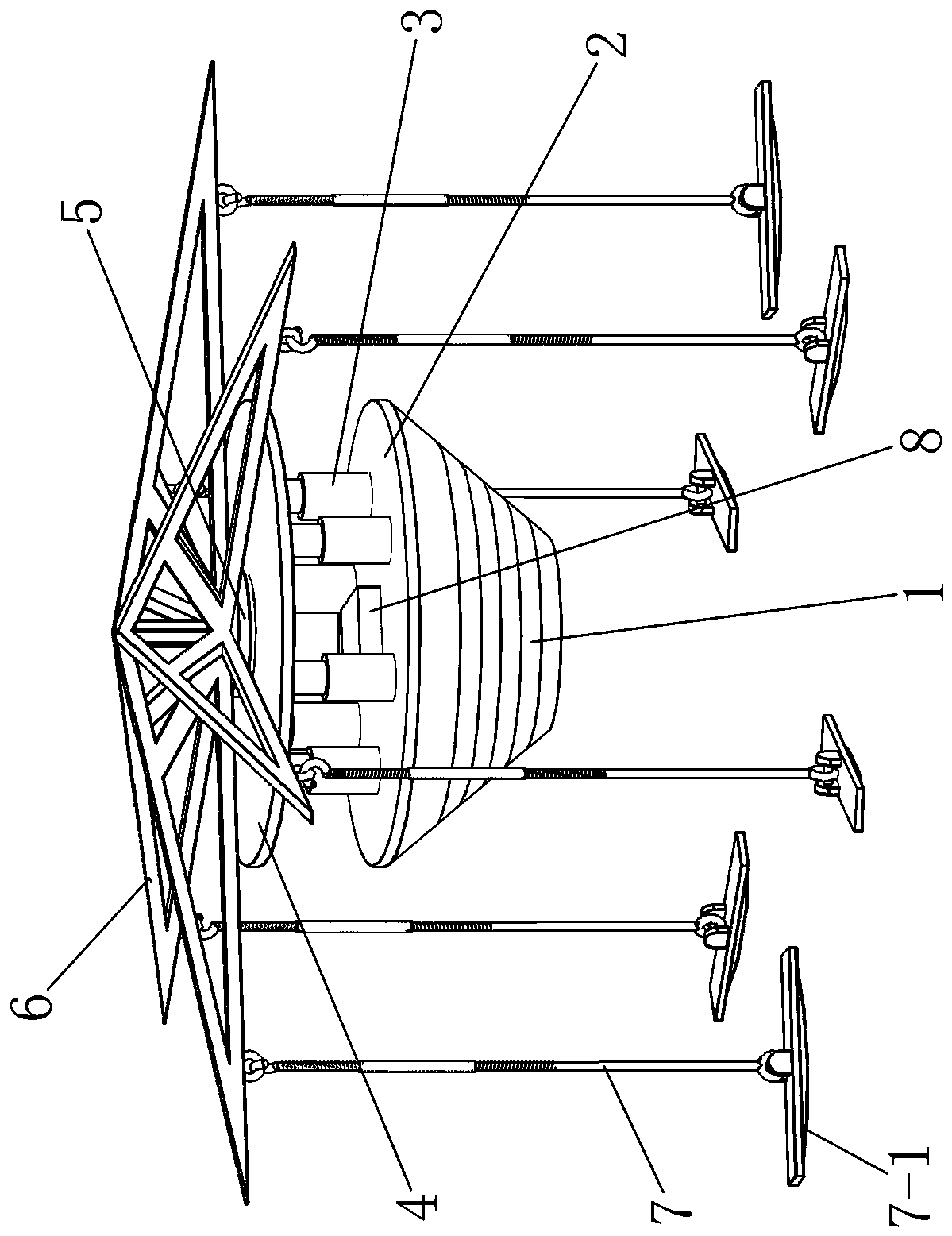

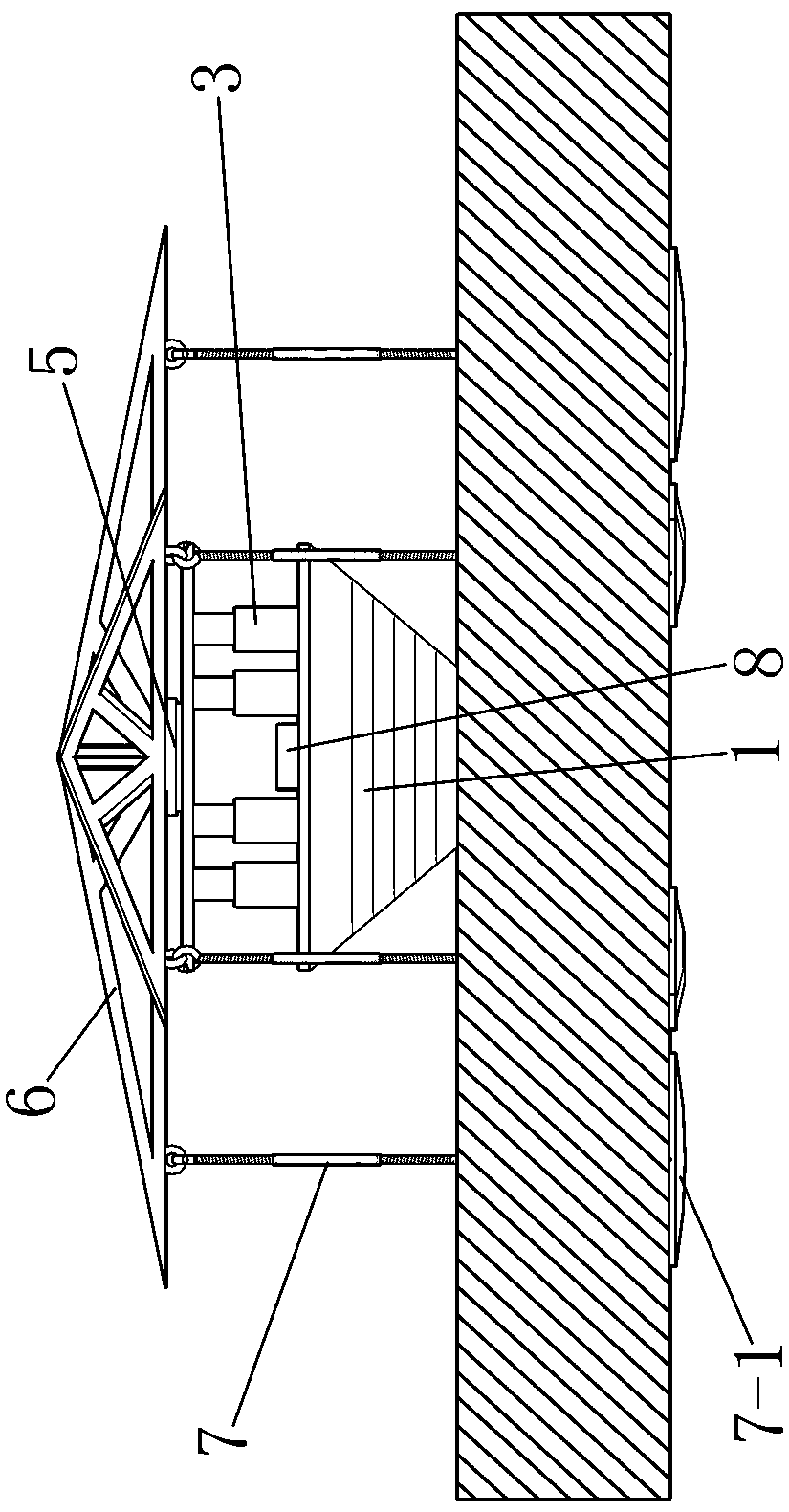

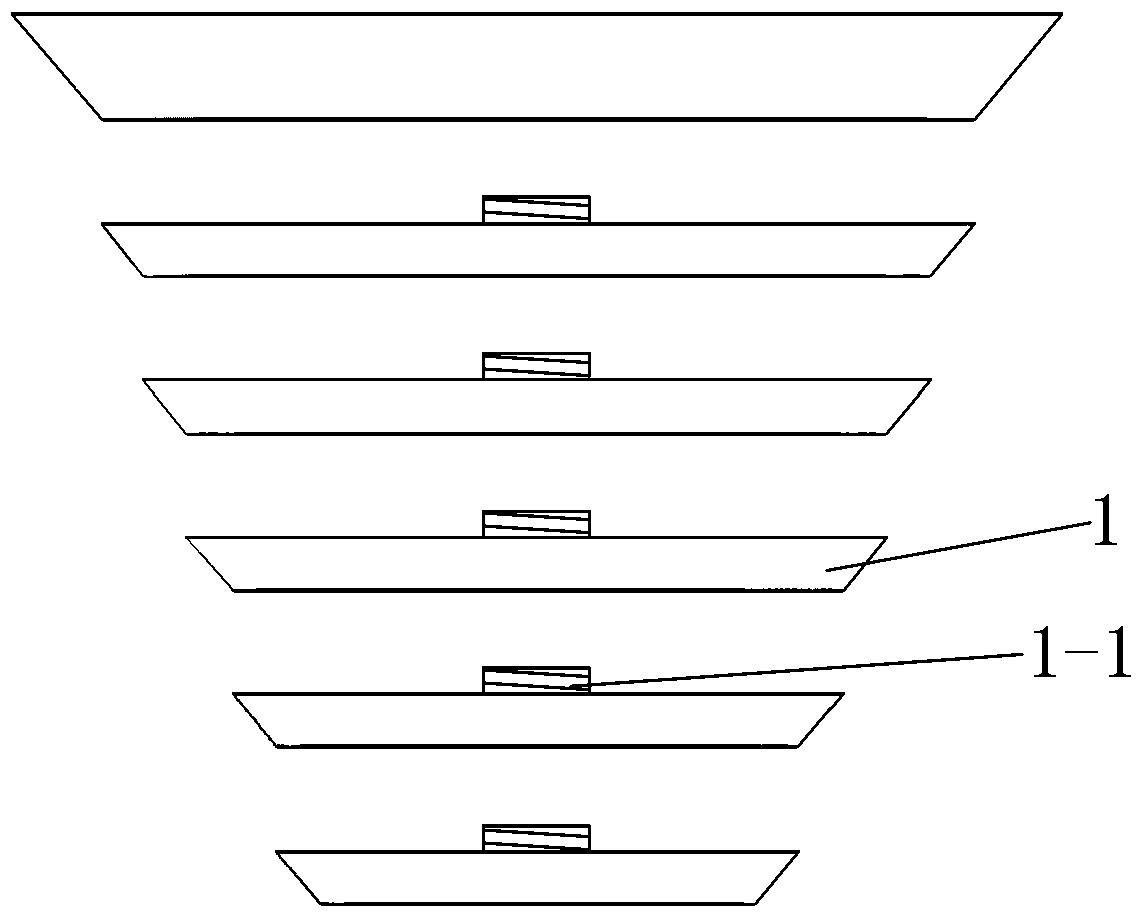

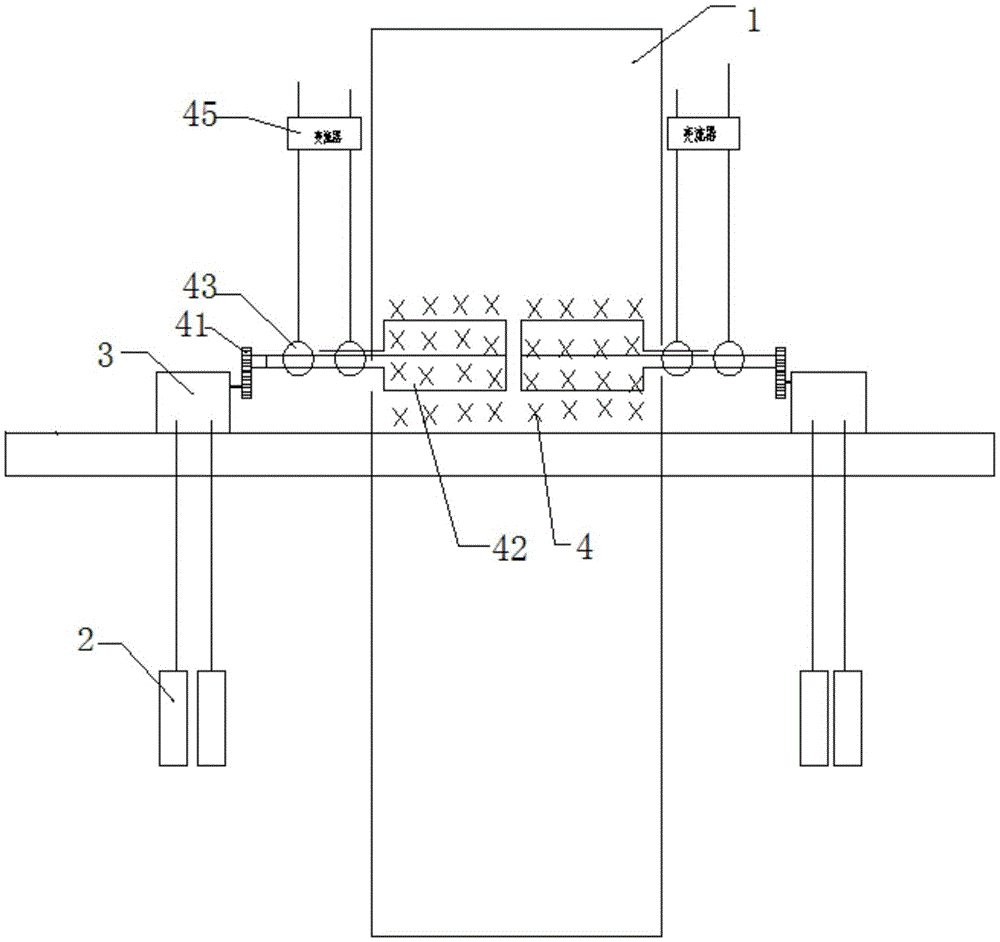

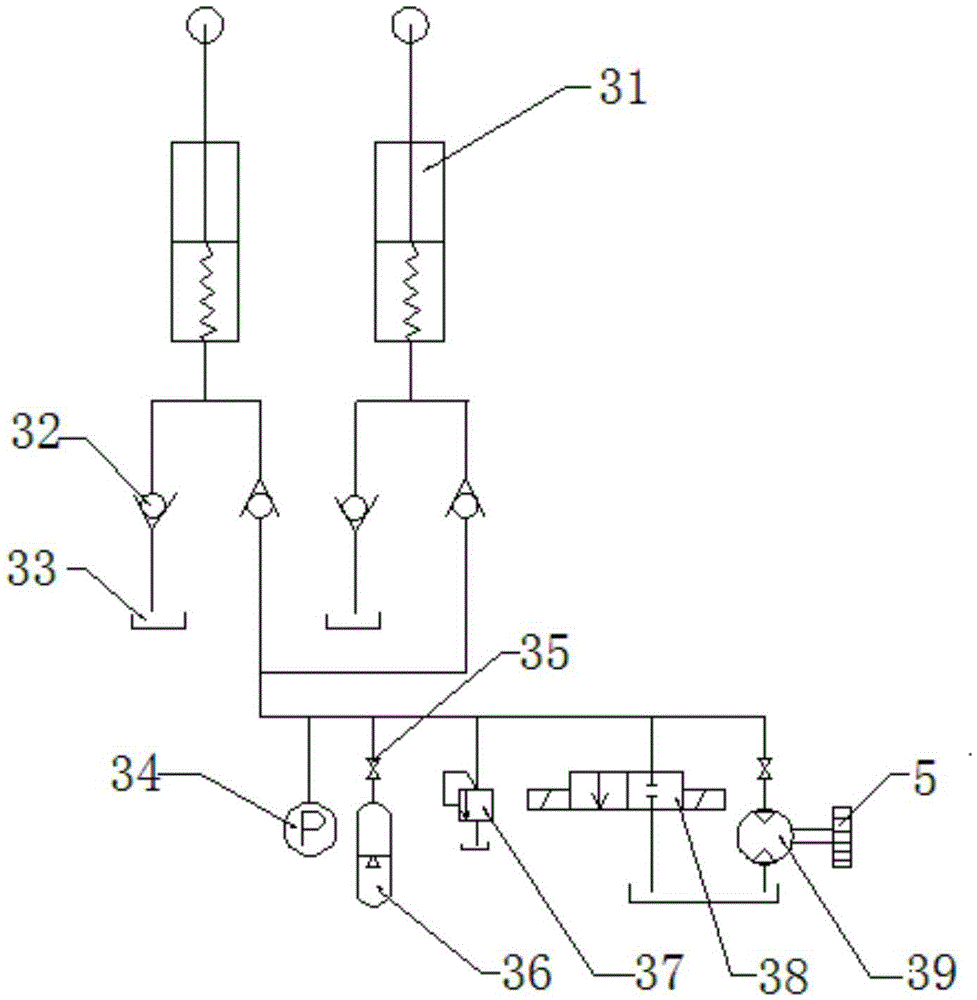

A wave energy generating device based on float and hydraulic pressure

InactiveCN103912439BScientific and rational useSmooth rotationMachines/enginesEngine componentsWave power generationEngineering

The invention provides a floater-based and hydraulic wave power generation assembly which comprises a mounting platform, floaters, conversion devices and a power generator. The conversion devices and the power generator are mounted on the mounting platform, the floaters float on a sea surface and are connected with the hydraulic or mechanical conversion devices, and the conversion devices are connected with the power generator. The floaters rise and fall along with waves on the sea surface, rise and fall movement is transmitted onto the conversion devices and is converted into a movement mode by the conversion devices, and the movement mode is used for driving the power generator to work (and is most commonly used for driving a shaft of an engine to rotate), so that power can be generated. The floater-based and hydraulic wave power generation assembly has the advantages that the floater-based and hydraulic wave power generation assembly is small in size, simple in structure, low in cost and high in power generation efficiency, can be mounted on an offshore working platform and even certain large ships and can be used on the offshore working platform and the certain large ships, and the power can be stably outputted.

Owner:ZHEJIANG OCEAN UNIV

A raw material homogenization process for dead-burned magnesia shaft kiln

The patent of the present invention relates to a material homogenization process for dead-burned magnesia shaft kiln, including fine grinding, primary mixing and homogenization, ball pressing, secondary mixing and homogenization, and sintering. The raw materials are and fuel. First, the natural high-calcium magnesite powder ore and crushed ore and the natural high-silicon magnesite powder ore and crushed ore are finely ground and mixed and homogenized; then the primary mixed and homogenized material is briquetted; then the briquette is mixed with fuel Carry out secondary mixing and homogenization together, and finally sinter the secondary mixing and homogenizing material at 1500-1800°C to obtain dead-burned magnesia. The method of the invention has the advantages of simple process flow, high product density and the like, and can improve the high temperature resistance and corrosion resistance of the refractory material due to the existence of the forsterite phase with a high melting point.

Owner:海城市军刚中档镁砂有限公司

Tobacco raw material classifying and grouping method

ActiveCN102920005BScientific useScientific and rational useTobacco preparationMaterial analysisGroup methodComputer science

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

Method of pulping and papermaking

InactiveCN1793492AScientific and rational useAlleviate the growing shortagePulping with inorganic basesRaw material divisionPapermakingEngineering

The method discloses a pulping paper making method. It includes preparing raw material, boiling pulping, and using paper pulp to manufacture paper. The preparing raw material includes cutting a Canada yellow flower into flap with 2-3cm length, 1-2cm width, 3-5mm thickness and drying it to form herbage absolute dry raw material. The boiling pulping includes adding sodium hydroxide and modification anthraquinone into herbage absolute dry raw material to form solid raw material in proportion of 206-284 : 0-2: 1000, and adding water with 1: 3.5-4.5 solid liquid weight ratio; controlling the temperature between 155 to 165 centigrade degree, and time between 90 to 120min. The invention can reduce wood using consumption, and manufacture high quality paper.

Owner:ZHEJIANG SCI-TECH UNIV

Quartz sand purification process without washing procedure

ActiveCN112624125ASignificantly progressiveLow processing and running costsSilicaFluidized bed dryingAcid washing

The invention relates to a quartz sand purification process without a washing procedure, which comprises the steps of deacidifying acid-washed and purified quartz sand until the mass of acid liquor in the quartz sand is less than 10%, feeding the deacidified quartz sand into a fluidized bed dryer, and drying at the temperature of 350-750 DEG C under a hot air condition, and cooling the dried quartz sand material to obtain the high-purity quartz sand material. According to the method, the washing procedure is omitted, a large amount of environmental protection and production investment are saved, the water utilization and wastewater treatment operation cost is saved, the production cost is reduced, and meanwhile, the impurity removal effect can be further achieved in the fluidized bed drying process.

Owner:HUANGGANG NORMAL UNIV +1

Method for producing fuel oil and lubricating oil base oil through hydrogenation of full fraction coal tar

ActiveCN103146424BScientific and rational useInsufficient reliefTreatment with hydrotreatment processesTarEconomic benefits

The invention relates to a method for producing fuel oil and lubricant base oil by hydrogenating all fractions of coal tar. The method comprises the following steps of: performing pressure reduction on the all fractions of coal tar by virtue of a pressure reduction valve after hydroprocessing on the all fractions of coal tar is finished, and flashing to separate out a light product and a heavy product; performing isodewaxing on the heavy product; and fractioning the heavy product, successively together with the light product, through a heat high fraction separator, a cold high fraction separator, a cold low fraction separator and a fraction tower to obtain the fuel oil and the lubricant base oil which are good in quality and meet a state standard request. The method is simple in process procedures, easy to control, and safe and stable in operation; and the all fractions of coal tar can be scientifically and reasonably utilized, the production economic benefit is further improved, and a certain active function in overcoming the defect of the fuel oil and the lubricant base oil in China is achieved.

Owner:SHENMUFUYOU ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com