Tobacco raw material classifying and grouping method

A technology of classification method and grouping method, which is applied to tobacco, analyzing materials, preparing tobacco, etc., can solve problems such as scientific and reasonable combination standards, and achieve the effect of improving quality and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

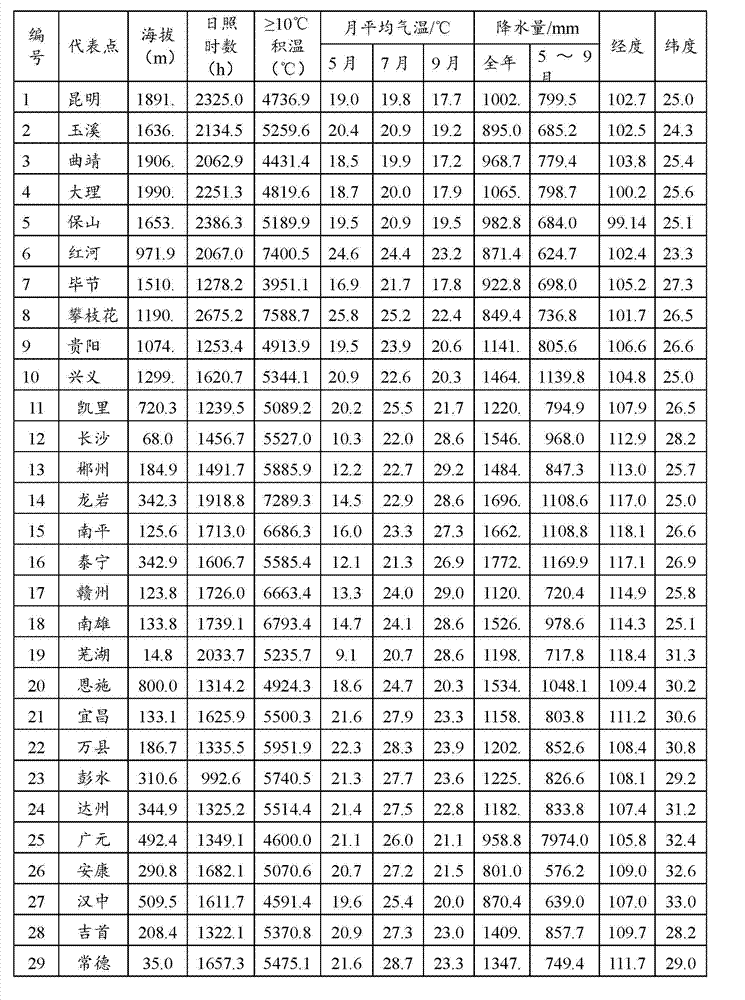

[0017] In this embodiment, the classification and grouping of flue-cured tobacco leaves of the same year and the same grade in 29 representative points in the tobacco leaf raw material planting area is taken as an example for illustration.

[0018] Step 1): PCA multi-index compression

[0019] Generally speaking, there are many indicators to describe the ecological characteristics of tobacco raw material planting areas, and both geographical and meteorological aspects should be considered. To this end, 10 representative indicators were selected, including altitude, sunshine, accumulated temperature ≥10°C, average temperature in May, July, and September, annual precipitation, precipitation from May to September, longitude, and latitude, and recorded them respectively. X1, X2, ..., X10, see Table 1 for specific data.

[0020] Table 1. Index values of ecological characteristics of representative points

[0021]

[0022] .

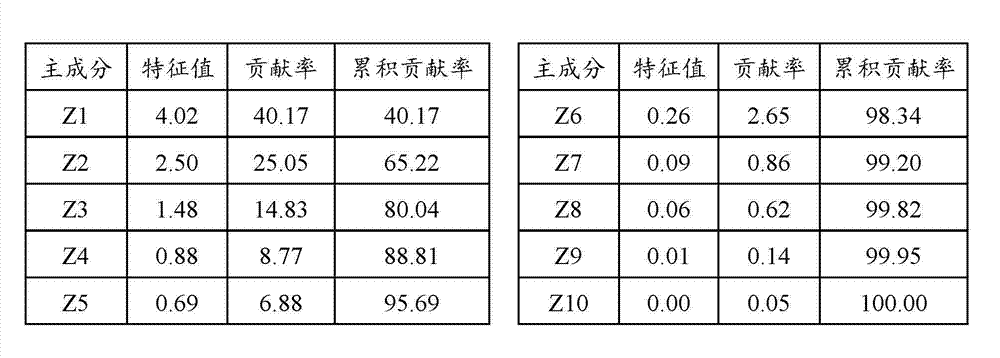

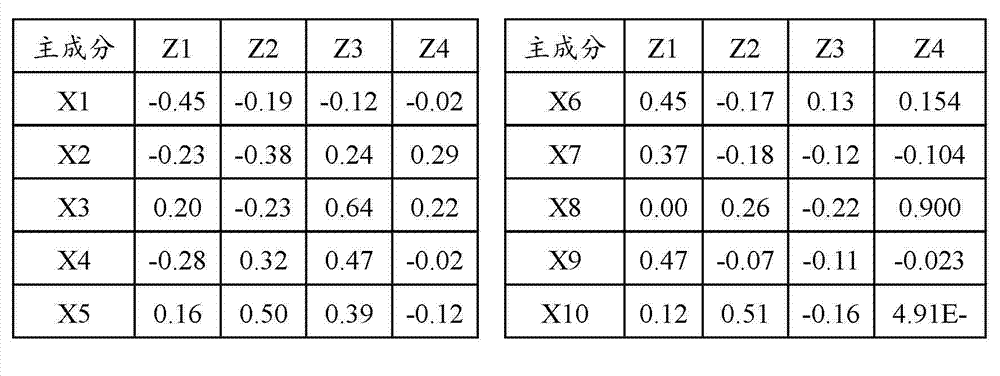

[0023] The DPS software was used to conduct prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com