Preparation technology of methanol-to-hydrocarbon combustion gas for urban pipelines

A production process and technology of hydrocarbon gas, applied in the direction of fuel, petroleum industry, gas fuel, etc., can solve the problems of low methane yield, resource utilization and economic uneconomical, etc., achieve high energy saving benefits, scientific and reasonable energy utilization, and solve The effect of data waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

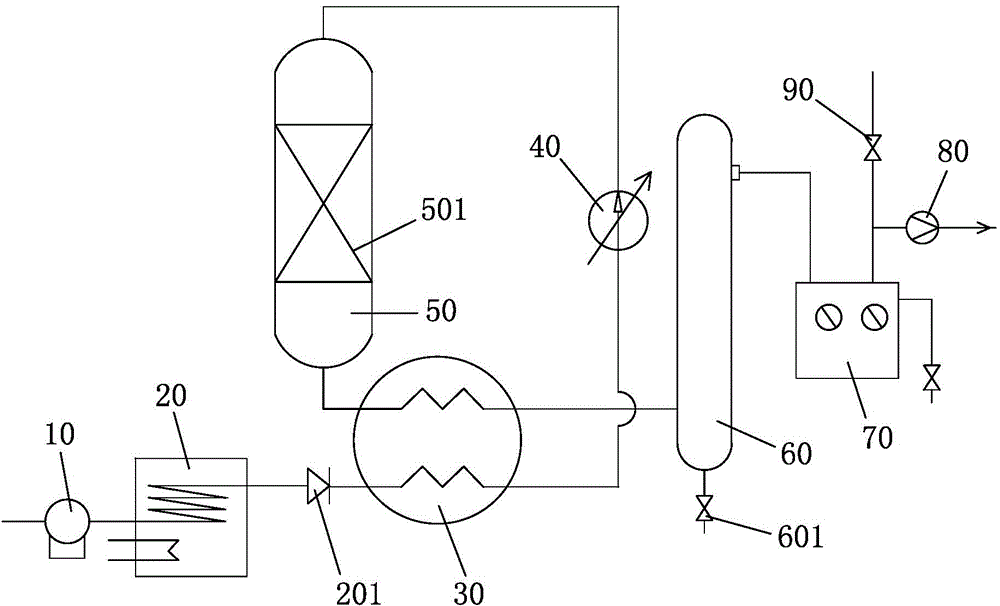

[0044] refer to figure 1 As shown, the present invention discloses a process for producing hydrocarbon gas from methanol for urban pipelines, using methanol as a raw material as a natural gas or petroleum gas energy carrier, which is converted into hydrocarbon gas through this process flow, specifically, the present invention The manufacturing process includes the following steps:

[0045] a) Methanol is transferred from the raw material tank through the pump 10 to the heater 20 for preheating, and the preheating temperature is 60°C;

[0046] b) The preheated methanol is sent to the heat exchanger 30, and the methanol continues to be heated in the heat exchanger 30 and gasifies to form a gas-liquid mixture. In this embodiment, the combined figure 1As shown, a one-way valve 201 is installed on the pipeline where the preheated methanol is delivered to the heat exchanger 30, and the temperature range in the heat exchanger 30 is 100-150°C;

[0047] c) The gas-liquid mixture fo...

Embodiment 2

[0053] refer to figure 1 As shown, the present invention discloses a process for producing hydrocarbon gas from methanol for urban pipelines. The process of the present invention comprises the following steps:

[0054] a) Methanol is transferred from the raw material tank through the pump 10 to the heater 20 for preheating, and the preheating temperature is 100°C;

[0055] b) The preheated methanol is transported to the heat exchanger 30, the methanol continues to be heated in the heat exchanger 30 and gasifies to form a gas-liquid mixture, and the preheated methanol is transported to the pipeline of the heat exchanger 30 for installation There is a one-way valve 201;

[0056] c) The gas-liquid mixture formed after step b continues to be transported to the superheater 40 through the pipeline, and the superheater 40 further heats the gas-liquid mixture. The heating temperature is 370°C, and the methanol is completely vaporized in the superheater 40 ;

[0057] d), the output...

Embodiment 3

[0062] refer to figure 1 As shown, the present invention discloses a process for producing hydrocarbon gas from methanol used in urban pipelines. Methanol is used as a raw material as a natural gas or petroleum gas energy carrier, and is converted into hydrocarbon gas through this process flow. Specifically, the present invention The manufacturing process includes the following steps:

[0063] a) Methanol is transferred from the raw material tank through the pump 10 to the heater 20 for preheating, and the preheating temperature is 75°C;

[0064] b) The preheated methanol is sent to the heat exchanger 30, and the methanol continues to be heated in the heat exchanger 30 and gasifies to form a gas-liquid mixture; the preheated methanol is sent to the pipeline of the heat exchanger 30 for installation There is a one-way valve 201; the temperature inside the heat exchanger 30 is 150°C;

[0065] c) The gas-liquid mixture formed after step b continues to be transported to the sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com