Method for producing fuel oil and lubricant base oil by hydrogenating all fractions of coal tar

A technology of lubricating oil base oil and coal tar, which is applied in the field of coal chemical industry, can solve the problems that the production economic benefits are difficult to further improve, and there is no further rational use, and achieve the effects of improving production economic benefits, easy control, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

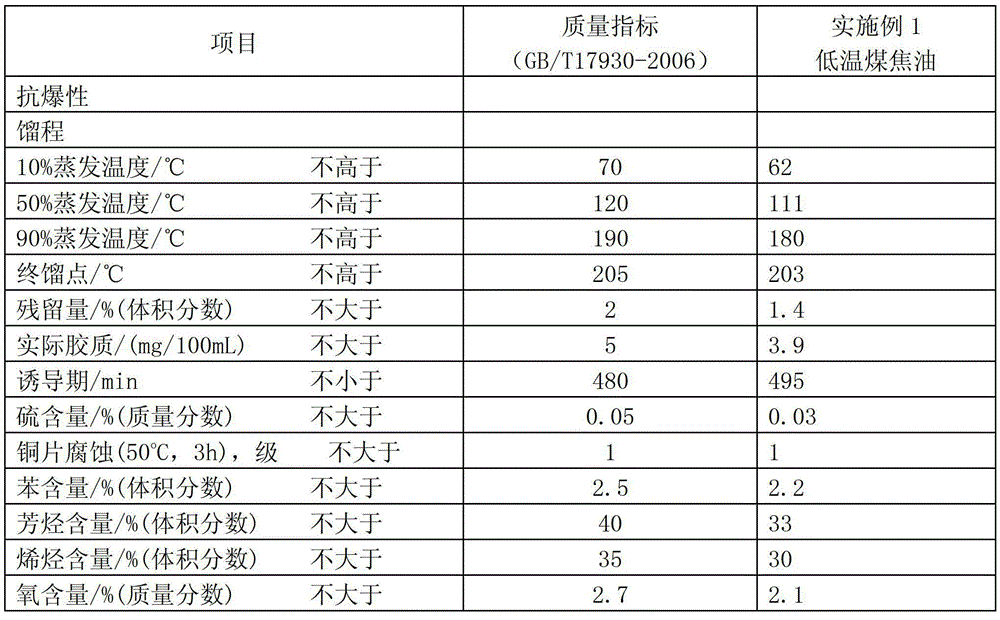

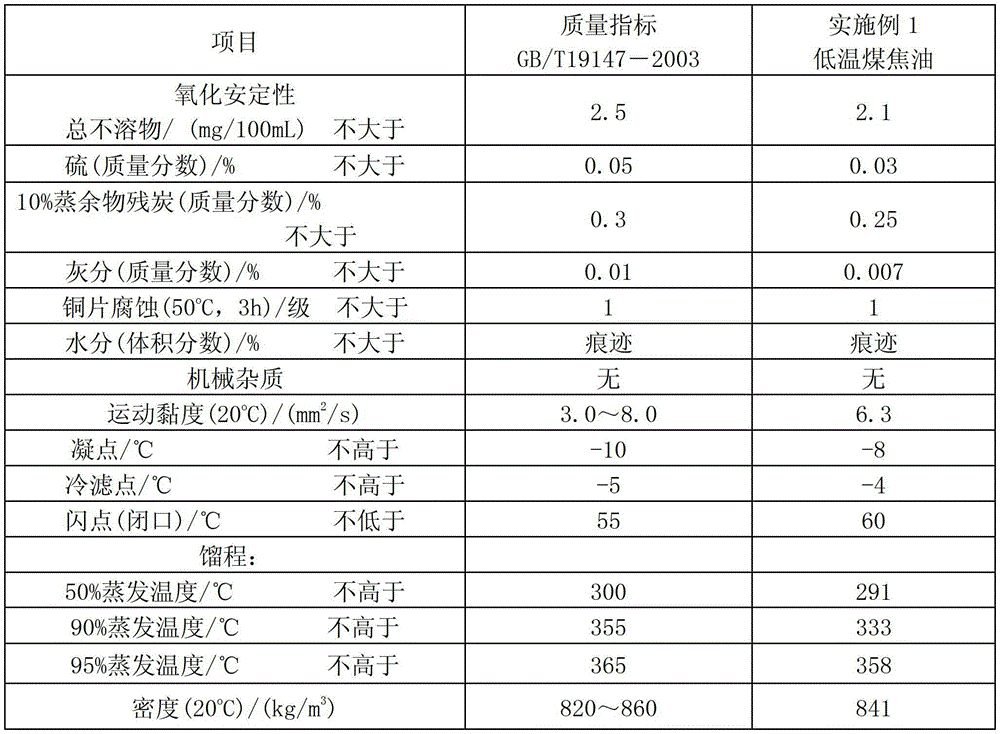

Embodiment 1

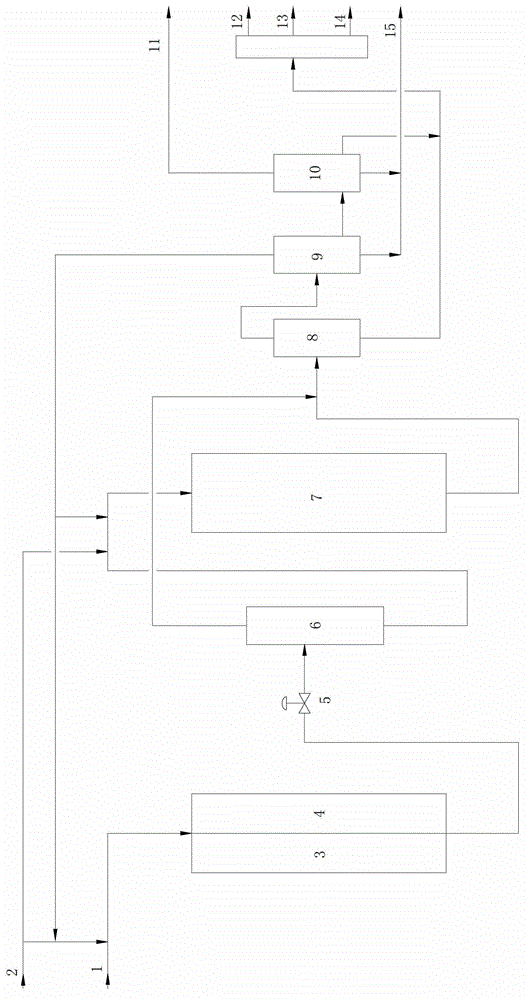

[0017] Now take the full fraction low-temperature coal tar 1 as an example, see figure 1 , the method for hydrogenation of fuel oil and lubricating base oil consists of the following steps:

[0018] (1) Dehydration and deslagging post-treatment of the whole fraction of low-temperature coal tar 1 according to conventional methods;

[0019] (2) The low-temperature coal tar 1 after dehydration and deslagging is mixed with hydrogen 2 and sent to the first hydrogenation reactor 3, which is filled with TK-10 hydrogenation protection agent (Topsoe company), RN -5030 Hydrodemetallization Agent (Criterion Company), the inlet temperature of TK-10 Hydrodemetallization Agent is 230°C, the reaction temperature of RN-5030 Hydrodemetallization Agent is 240°C, the pressure is 12MPa, and the liquid space velocity is 0.3 h -1 , the volume ratio of oil to hydrogen is 1:1500, after the reaction is completed, it is sent to the second hydrogenation reactor 4, and the second hydrogenation reactor ...

Embodiment 2

[0023] Now taking full-fraction low-temperature coal tar 1 as an example, the method for hydrogenating fuel oil and lubricating base oil consists of the following steps:

[0024] (1) Dehydration and deslagging post-treatment of the whole fraction of low-temperature coal tar 1 according to conventional methods;

[0025] (2) The low-temperature coal tar 1 after dehydration and deslagging is mixed with hydrogen gas 2 and sent to the first hydrogenation reactor 3. The first hydrogenation reactor 3 is filled with a hydrogenation protecting agent and a hydrodemetallization agent for hydrogenation The inlet temperature of the protective agent is 230°C, the reaction temperature of the hydrodemetallization agent is 250°C, the pressure is 14MPa, and the liquid space velocity is 0.2h -1 , the volume ratio of oil to hydrogen is 1:1500, after the reaction is completed, it is sent to the second hydrogenation reactor 4, and the second hydrogenation reactor 4 is equipped with a hydrodesulfuri...

Embodiment 3

[0029] Now taking full-fraction low-temperature coal tar 1 as an example, the method for hydrogenating fuel oil and lubricating base oil consists of the following steps:

[0030] (1) Dehydration and deslagging post-treatment of the whole fraction of low-temperature coal tar 1 according to conventional methods;

[0031](2) The low-temperature coal tar 1 after dehydration and deslagging is mixed with hydrogen gas 2 and sent to the first hydrogenation reactor 3. The first hydrogenation reactor 3 is filled with a hydrogenation protecting agent and a hydrodemetallization agent for hydrogenation The inlet temperature of the protective agent is 240°C, the reaction temperature of the hydrodemetallization agent is 260°C, the pressure is 16MPa, and the liquid space velocity is 0.5h -1 , the volume ratio of oil to hydrogen is 1:1800, after the reaction is completed, it is sent to the second hydrogenation reactor 4, and the second hydrogenation reactor 4 is equipped with a hydrodesulfuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com