A tooth-shaped multi-pole T-connection projection welding method for cable trays

A cable tray, multi-pole technology, applied in the field of resistance projection welding, can solve the problems of unstable quality, large deformation, large energy consumption, etc., and achieve the effects of reducing production costs, improving product quality, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

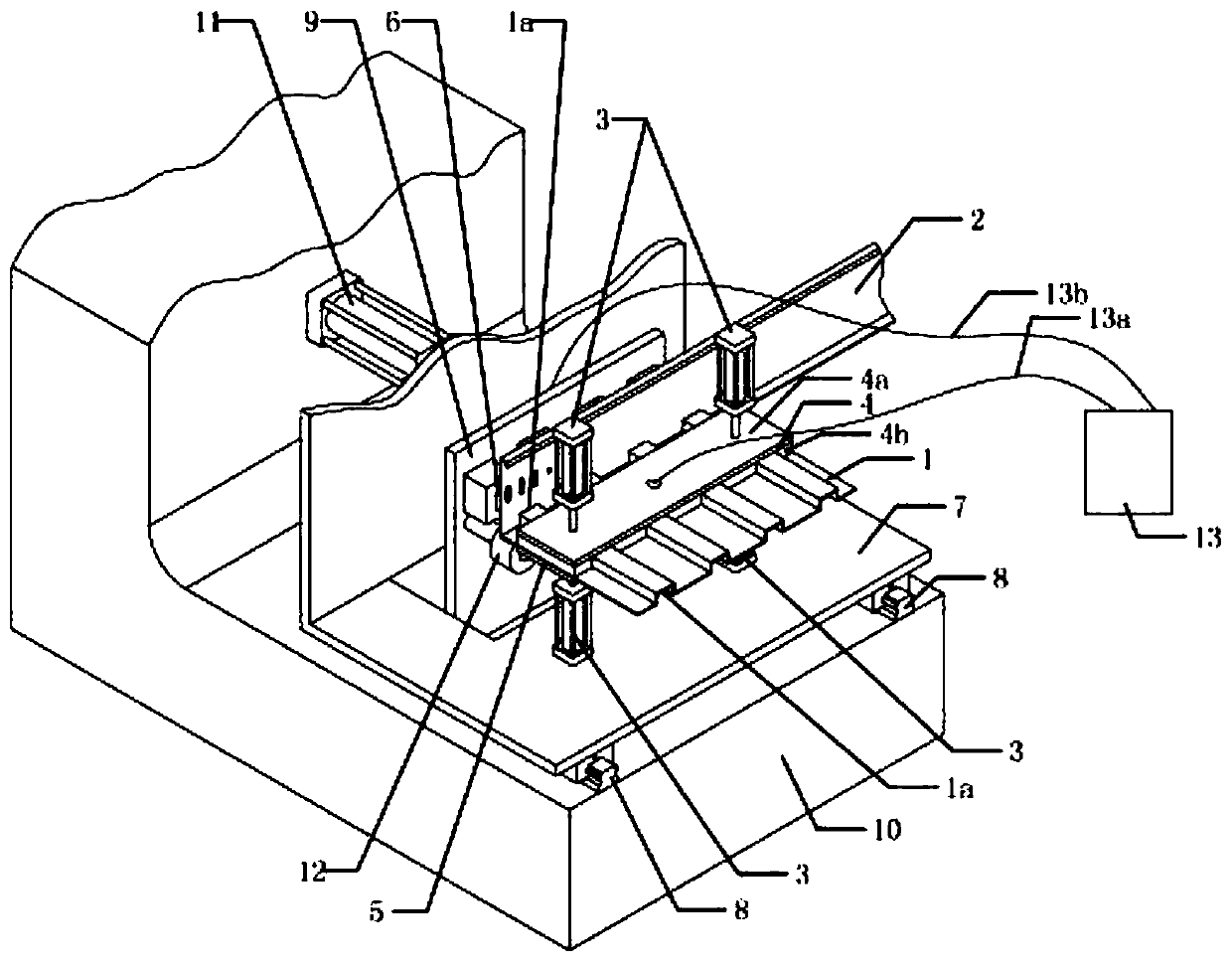

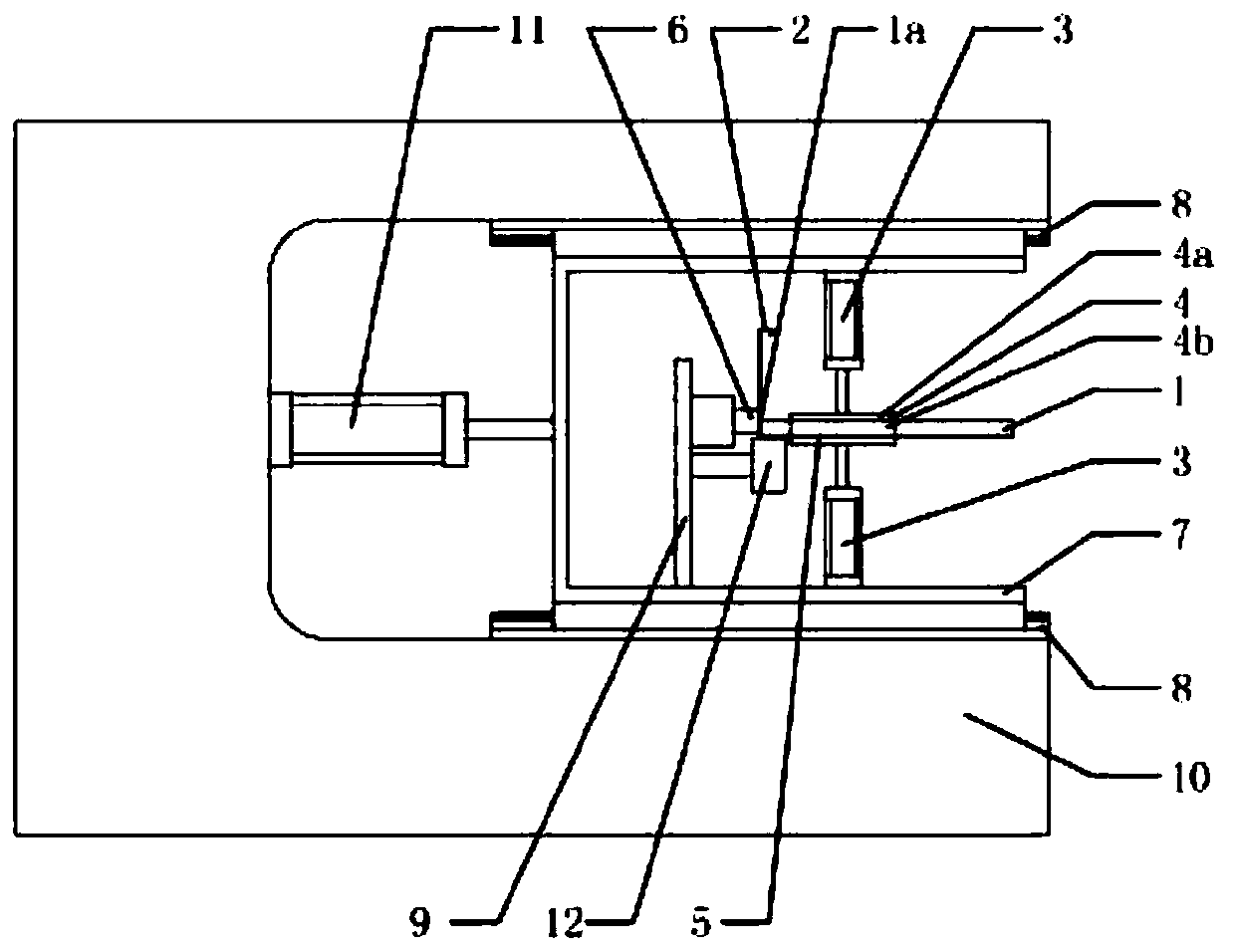

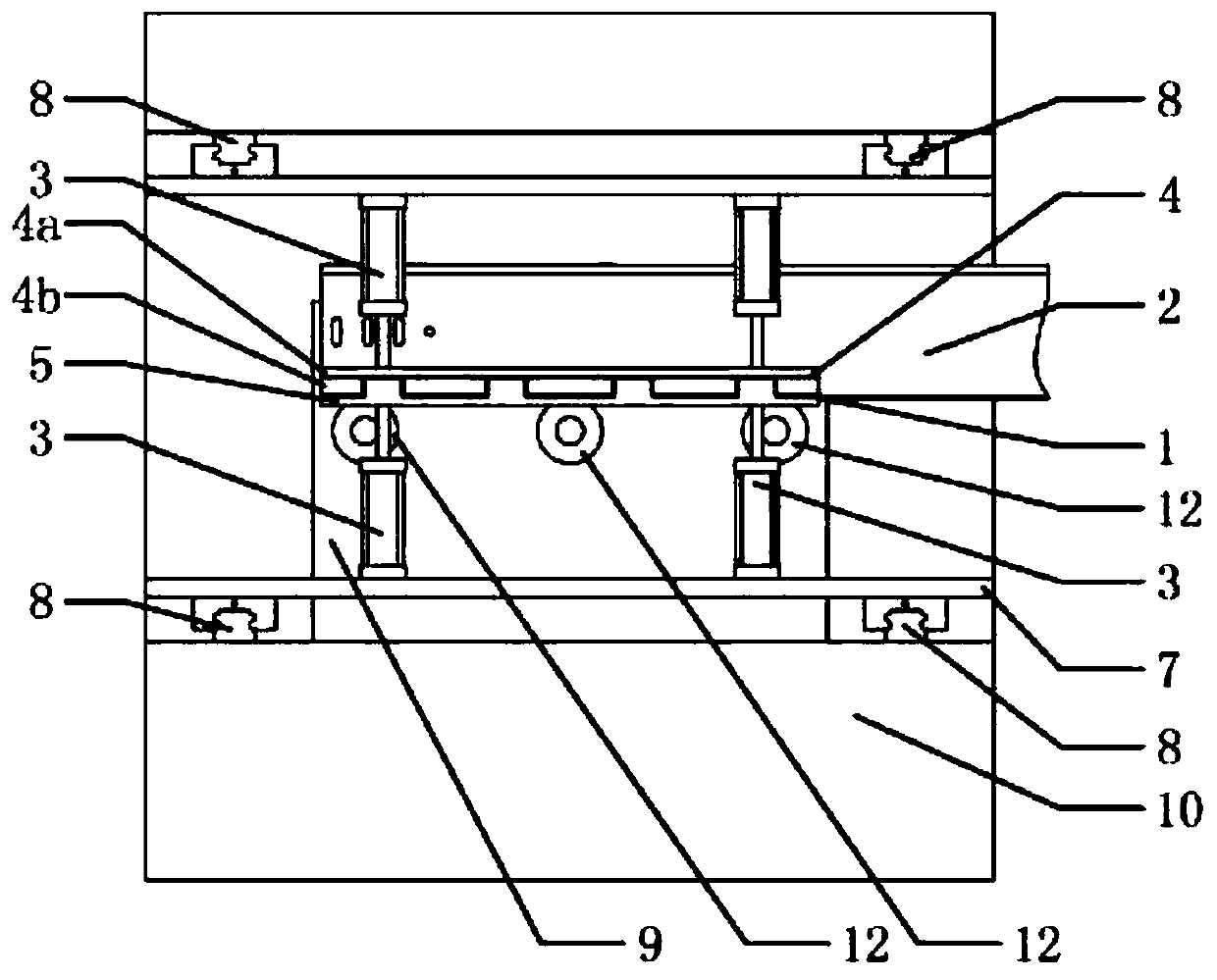

[0030] The cable tray is composed of the bottom plate 1 of the tray, the left side panel 2 of the tray, and the right side panel 14 of the tray. The plates 14 are welded separately. The base plate tooth pole 1a is made at the end part of the bridge base plate 1, and the size, shape and quantity of the tooth shape are set according to the needs of the product.

[0031] The tooth-shaped pole of the bottom plate is composed of a plurality of continuous convex points.

[0032] The tooth-shaped pole of the bottom plate is composed of a plurality of discontinuous convex points.

[0033] The tooth-shaped pole of the bottom plate has a convex point in a triangle or a semicircle.

[0034] The left side plate of the bridge frame and the right side plate of the bridge frame are provided with a plurality of convex points on the lower side of the side plate corresponding to the position of the bottom plate of the bridge frame to be welded to form the side plate convex points.

[0035] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com