Cerate composite additive and solidification liquid for copper foil surface solidification treatment and application method of cerate composite additive and solidification liquid

A composite additive and surface curing technology, which is applied in the field of cerium salt composite additives and curing liquid for copper foil surface curing treatment, can solve the problems of side corrosion, pollution of the environment, and decreased bonding force between copper foil and insulating substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

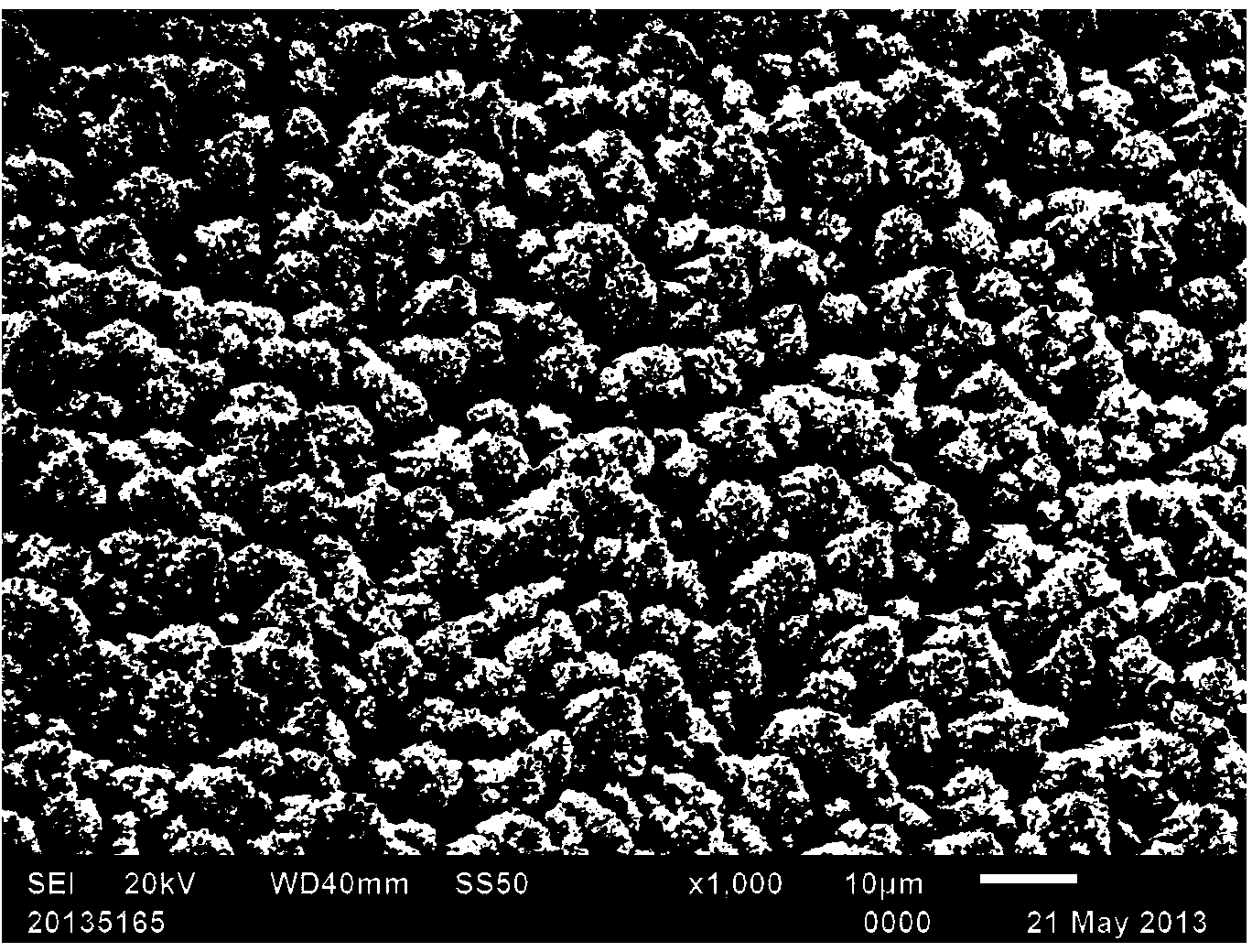

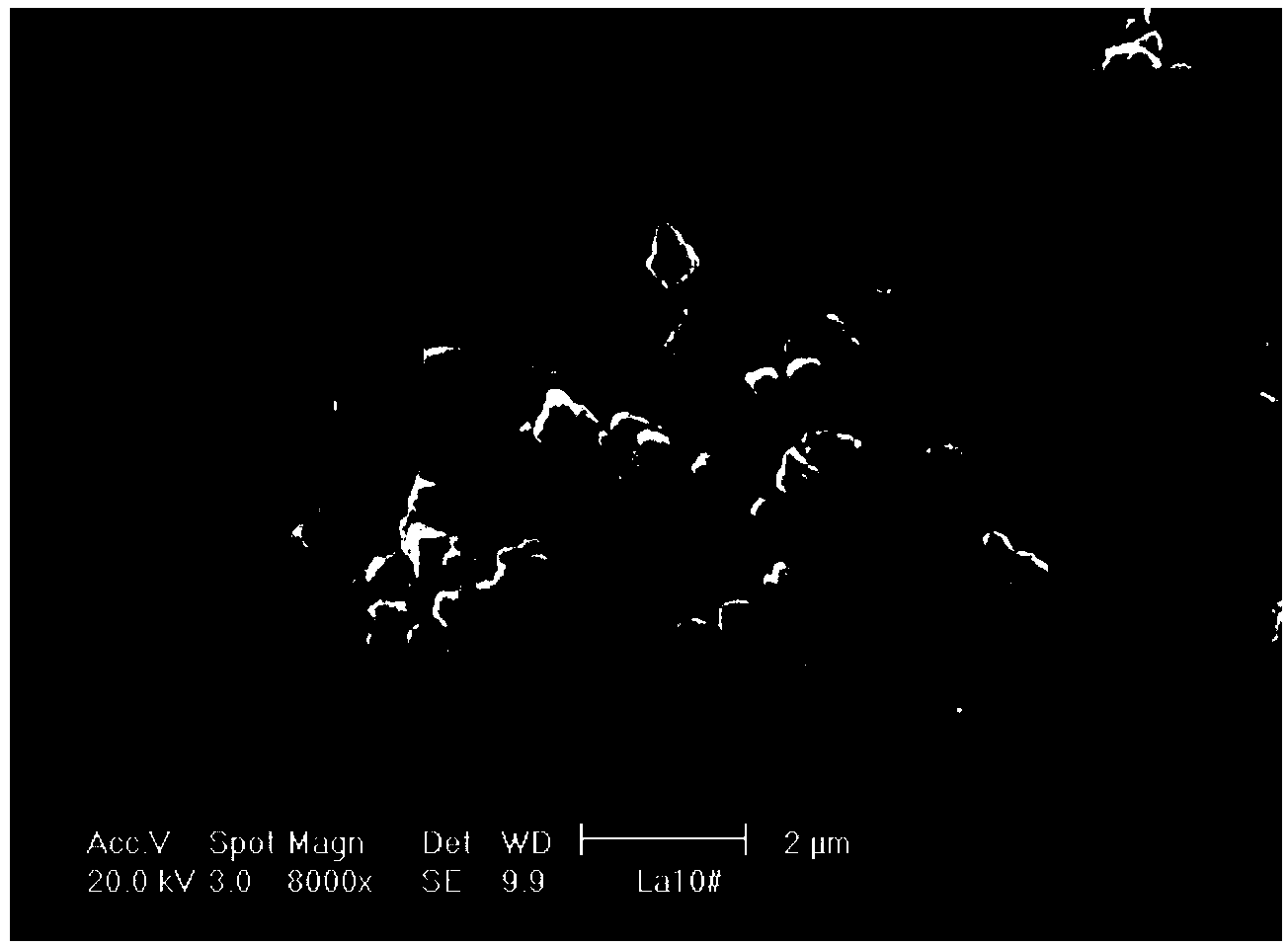

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments.

[0021] The overall process flow of copper foil surface treatment is as follows:

[0022] Raw foil → degreasing → washing with water → removing oxide film → washing with water → roughening → washing with water → curing → washing with water → passivation → washing with water → hot air drying → coating with silane coupling agent. The additive of the present invention is used in the surface curing treatment of copper foil Process.

[0023] Preparation of curing fluid

[0024] Recipe 1: First add 500ml of deionized water to a 1 liter electroplating tank, and then add 130g accurately weighed zinc sulfate heptahydrate, 35g nickel sulfate, 45g sodium sulfate, 30-50g ammonium sulfate, and 0.4-0.7 cerium sulfate. g, 8-15mL of ammonia (20%), adjust the pH to 3-4, and finally dilute the volume to 1L with deionized water to make the required solidification liquid.

[0025] Recipe 2: First add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com