Preparation and desulfurization applications of flower-like iron-doped cerium dioxide with porous structure

A porous structure, ceria technology, used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of poor selectivity, poor activity of selective oxidation catalysts, stable It can achieve good activity and selectivity, excellent anti-sulfation ability and stability, and is conducive to dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

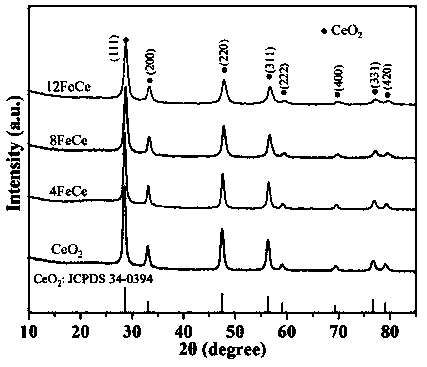

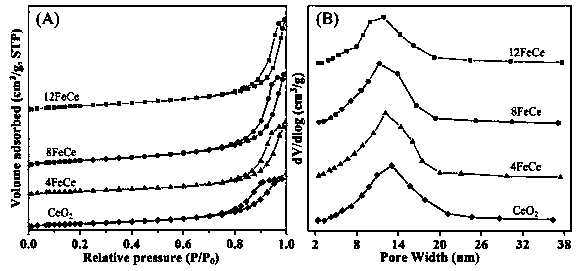

[0037] A preparation method of flower-like iron-doped ceria with porous structure: weigh 4.47 g (12.0 mmol) of CeCl 3 ·7H 2 O and 0.13 g (0.48 mmol) of FeCl 3 ·6H 2O was dissolved in 30 mL and 10 mL of distilled water respectively. After dissolving, the two solutions were mixed and 0.5 g of citric acid, 0.1 g of urea and 20 mmol of PVP were added. After dissolving, 10 mL of 10% ammonia water was added dropwise, and then at room temperature Stir at high speed for 20 min, then transfer the above solution to a 100 mL autoclave, hydrothermally treat at 120 °C for 24 h, then cool naturally at room temperature, wash the precipitate with absolute ethanol and distilled water three times each, and dry the obtained powder at 80 °C After drying for 12 h, the temperature was raised to 500 °C at a rate of 5 °C / min and kept for 2 h to obtain the final product flower-shaped iron-doped ceria, which was named 4FeCe.

Embodiment 2

[0039] A preparation method of flower-like iron-doped ceria with porous structure: weigh 5.2 g (12.0 mmol) of Ce(NO 3 ) 3 ·6H 2 O and 0.194 g (0.96 mmol) of Fe(NO 3 ) 3 9H 2 O was dissolved in 30 mL and 10 mL of distilled water respectively. After dissolving, the two solutions were mixed and 0.5 g of citric acid, 0.2 g of urea and 20 mmol of PVP were added. After dissolving, 10 mL of 10% ammonia water was added dropwise, and then at room temperature Stir at high speed for 30 min, then transfer the above solution to a 100 mL autoclave, hydrothermally treat at 150 °C for 24 h, then cool naturally at room temperature, wash the precipitate with absolute ethanol and distilled water three times each, and dry the obtained powder at 100 °C Drying for 12 h, followed by calcination at 500 °C (heating rate of 2 °C / min) for 3 h to obtain the final product flower-like iron-doped ceria, which was named 8FeCe.

Embodiment 3

[0041] A preparation method of flower-like iron-doped ceria with porous structure: weigh 5.2 g (12.0 mmol) of Ce(NO 3 ) 3 ·6H 2 O and 0.388 g (1.44 mmol) of Fe(NO 3 ) 3 9H 2 O was dissolved in 30 mL and 10 mL of distilled water respectively. After dissolving, the two solutions were mixed and 0.5 g of citric acid, 0.3 g of urea and 20 mmol of PVP were added. After dissolving, 10 mL of 10% ammonia water was added dropwise, and then at room temperature Stir at high speed for 20 min, then transfer the above solution to a 100 mL autoclave, hydrothermally treat at 140 °C for 24 h, then cool naturally at room temperature, wash the precipitate with absolute ethanol and distilled water three times each, and put the obtained powder at 80 °C Drying for 12 h, followed by calcination at 500 °C (heating rate 5 °C / min) for 4 h to obtain the final product flower-like iron-doped ceria, which was named 12FeCe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com