Treatment method of electrolytic coloring of black color of aluminium alloy anodic oxidation film

A technology of anodized film and treatment method, applied in the direction of electrolytic paint, surface reaction electrolytic coating, coating, etc., can solve the problems of black film black impure, gray, brown and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

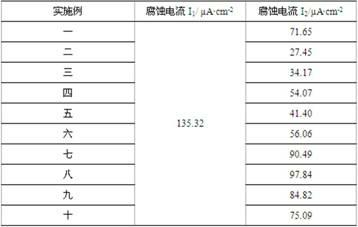

Examples

experiment example 1

[0027] A processing method for electrolytic blackening of anodized film of aluminum alloy. First, the aluminum alloy is pre-treated: the surface is deoxidized and then washed with water, and a mixed solution of sodium hydroxide (30g / L) and sodium carbonate (25g / L) is used for alkali treatment. After 1min, take out and wash with water, immerse in sodium hydroxide (50g / L) solution for alkaline etching, take out and wash after 1min, and immerse in nitric acid solution (200mL / L) to neutralize residual alkali and emit light, take out after 1min Washed and dried. After pretreatment, the aluminum alloy sample was used as the anode, the graphite electrode was used as the cathode, and the ratio of cathode to anode was 1:1. 3+ The anodic oxidation solution of 170g / L sulfuric acid was anodized for 40min, and the oxidation voltage was DC 15V. The anodized aluminum alloy is used as the cathode, the aluminum electrode is used as the anode, and the ratio of the cathode to the anode is 1:1. ...

experiment example 2

[0031] A processing method for electrolytic blackening of anodized film of aluminum alloy. First, the aluminum alloy is pre-treated: the surface is deoxidized and then washed with water, and a mixed solution of sodium hydroxide (30g / L) and sodium carbonate (25g / L) is used for alkali treatment. After 1min, take out and wash with water, immerse in sodium hydroxide (50g / L) solution for alkaline etching, take out and wash after 1min, and immerse in nitric acid solution (200mL / L) to neutralize residual alkali and emit light, take out after 1min Washed and dried. After pretreatment, the aluminum alloy sample was used as the anode, the graphite electrode was used as the cathode, and the ratio of cathode to anode was 1:1. 3+ The anodic oxidation solution of 170g / L sulfuric acid was anodized for 40min, and the oxidation voltage was DC 15V. The anodized aluminum alloy is used as the cathode, the aluminum electrode is used as the anode, and the ratio of the cathode to the anode is 1:1. ...

experiment example 3

[0035]A processing method for electrolytic blackening of anodized film of aluminum alloy. First, the aluminum alloy is pre-treated: the surface is deoxidized and then washed with water, and a mixed solution of sodium hydroxide (30g / L) and sodium carbonate (25g / L) is used for alkali treatment. After 1min, take out and wash with water, immerse in sodium hydroxide (50g / L) solution for alkaline etching, take out and wash after 1min, and immerse in nitric acid solution (200mL / L) to neutralize residual alkali and emit light, take out after 1min Washed and dried. After pretreatment, the aluminum alloy sample was used as the anode, the graphite electrode was used as the cathode, and the ratio of cathode to anode was 1:1. 3+ The anodic oxidation solution of 170g / L sulfuric acid was anodized for 40min, and the oxidation voltage was DC 15V. The anodized aluminum alloy is used as the cathode, the aluminum electrode is used as the anode, and the ratio of the cathode to the anode is 1:1. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com