Method for extracting white carbon black and rare-earth water purifying agent from waste rare-earth polishing powder

A technology of rare earth polishing powder and white carbon black, which is applied in the direction of chemical instruments and methods, rare earth metal compounds, process efficiency improvement, etc., and can solve the problem of low silicon oxide content in acid leaching residue, secondary pollution of rare earth ions, unutilization, etc. problems, to achieve the effect of broad market space, significant economic value, and obvious cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

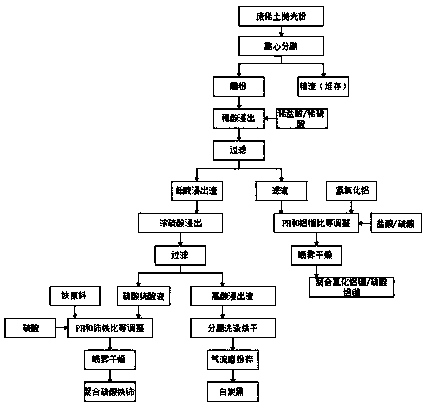

[0035] Such as figure 1 Shown, a kind of waste rare earth polishing powder extracts the method for white carbon black and rare earth water purifying agent, and concrete steps are as follows:

[0036] (1) Add water to the waste rare earth polishing powder to make a slurry with a solid concentration of 15-30%, and put it into a centrifuge for mineral separation to obtain the first material (coarse particles and heavy materials with a particle size of 5 microns or more) and the second material ( Fine particles and light materials with a particle size of less than 5 microns); through gravity separation, the silicon content of the second material is more than 30% higher than that of the first material, and is initially purified. Rare earth content of the first material increases, stockpiling and disposal;

[0037] (2) Add the second material described in step (1) into the dilute acid solution for reaction, the easily soluble alumina and lanthanum oxide in the second material are d...

Embodiment 2

[0053] Such as figure 1 Shown, a kind of waste rare earth polishing powder extracts the method for white carbon black and rare earth water purifying agent, and concrete steps are as follows:

[0054] (1) Add water to the waste rare earth polishing powder to make a slurry with a solid concentration of 15-30%, and put it into a centrifuge for mineral separation to obtain the first material (coarse particles and heavy materials with a particle size of 5 microns or more) and the second material ( Fine particles and light materials with a particle size below 5 microns);

[0055] (2) Add the second material described in step (1) into the dilute acid solution for reaction, the easily soluble alumina and lanthanum oxide in the second material are dissolved, and the silicon oxide powder, cerium oxide and Lanthanum fluoride is left in the low-acid leaching residue, and the reaction solution is filtered to obtain a low-acid filtrate and a low-acid leaching residue;

[0056] (3) Add alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com