Environment-friendly high-phosphorus chemical nickel additive

A technology of chemical nickel and additives, which is applied in the field of environment-friendly high-phosphorus chemical nickel additives. It can solve the problems of difficulty, lead inclusion and delay, etc., and achieve the effects of good nitric acid resistance, low porosity and dense coating

Active Publication Date: 2011-08-03

广州市二轻研究所股份有限公司 +1

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the traditional chemical nickel process stabilizer contains lead ions, etc. and the brightener contains cadmium compounds

These harmful heavy metals in traditional electroless nickel plating wastewater are extremely difficult to treat because of their small amount. When improperly treated and accumulated in the environment, they will cause serious pollution to the local environment. Due to the nature of the heavy metals themselves, the This kind of pollution has a long-term impact, and the pollution and damage to the environment and humans are catastrophic.

[0003] The addition of stabilizers in the chemical nickel plating solution can not only prevent or delay the spontaneous decomposition of the chemical nickel plating solution, but also stabilize the plating solution, and sometimes accelerate the reaction, affecting the phosphorus content and internal stress of the chemical nickel plating layer. Therefore, For a mature chemical nickel product, stabilizers are essential, but traditional stabilizers are mostly heavy metals such as lead ions, and lead and other heavy metals that are harmful to the environment and human body will inevitably be included in the chemical nickel plating

In recent years, people have higher and higher requirements for the brightness of chemical nickel. In order to obtain a beautiful coating, it is proposed to add a brightener to the chemical nickel plating solution. The traditional CdSO4 as a brightener has a good brightening effect, but due to the plating solution Cd in Cd will co-deposit with Ni-P alloy, which will cause great harm to the environment and human body. Therefore, it is expected to develop a new additive that can meet the requirements of stability and brightness and is non-toxic and harmless to the environment. environmentally friendly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0018] The raw material composition of environment-friendly high phosphorus chemical nickel additive is as shown in table 1:

[0019]

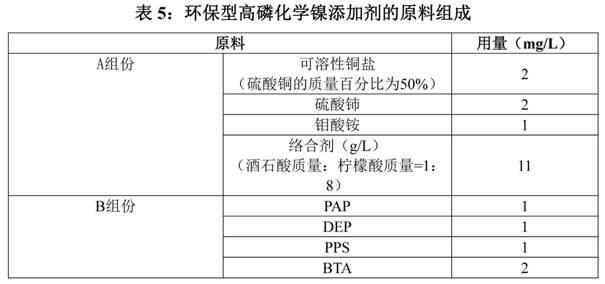

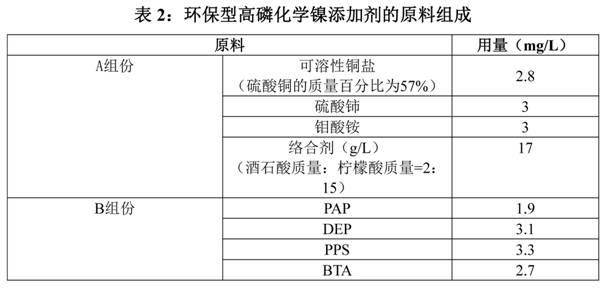

Embodiment 2

[0021] The raw material composition of environment-friendly high phosphorus chemical nickel additive is as shown in table 2:

[0022]

Embodiment 3

[0024] The raw material composition of environment-friendly high phosphorus chemical nickel additive is as shown in table 3:

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an environment-friendly high-phosphorus chemical nickel additive which consists of component A and a component B. The component A comprises the following raw materials based on concentration: 2-5mg / L soluble copper salt, 2-4mg / L cerous sulfate, 1-4mg / L ammonium molybdate and 11-23g / L complexing agent. The component B comprises the following raw materials based on concentration: 1-4mg / L PAP (propargyl alcohol propoxy compound), 1-3mg / L DEP (N, N-diethyl-propyne ammonium), 1-4mg / L PPS (pyridinium-1-pmpane-3-sulfonate) and 2-4mg / L BTA (benzotriazole). The formula of the environment-friendly high-phosphorus chemical nickel additive provided by the invention does not contain lead, cadmium and other heavy metal ions, thus the additive is non-toxic, harmless and environment-friendly. The additive is applied to a chemical nickel plating liquid to enable the plating liquid to be stable, thus the obtained plating is dense, has low porosity and good nitric acid resistance, and can achieve the effect that the nickel plating does not change color after being immersed in concentrated nitric acid for 5 minutes.

Description

technical field [0001] The invention relates to an environment-friendly high phosphorus chemical nickel additive. Background technique [0002] Due to the good corrosion resistance of high phosphorus chemical nickel, it is widely used in oil field equipment, electronic equipment, and automobile industry. However, traditional chemical nickel process stabilizers contain lead ions etc. and brighteners contain cadmium compounds. These harmful heavy metals in traditional electroless nickel plating wastewater are extremely difficult to treat because of their small amount. When improperly treated and accumulated in the environment, they will cause serious pollution to the local environment. Due to the nature of the heavy metals themselves, the This kind of pollution has a long-term impact, and the pollution and damage caused to the environment and human beings are catastrophic. [0003] The addition of stabilizers in the chemical nickel plating solution can not only prevent or de...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C18/32

Inventor 赵国鹏胡耀红张晓明

Owner 广州市二轻研究所股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com