Environment-friendly high-phosphorus nickel plating additive

An additive, environmentally friendly technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of large amount of addition and reduced plating rate, and achieve low porosity, excellent compactness, and plating solution. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment provides an environment-friendly high-phosphorus nickel plating additive, which includes component A and component B;

[0018] Wherein, the component A includes raw materials at the following concentrations: 10-15g / L sodium acetate trihydrate, 20-35g / L complexing agent, 5-10mg / L antimony potassium tartrate hemihydrate, 5-10mg / L L potassium iodide;

[0019] The component B includes raw materials at the following concentrations: 1-5 mg / L of hydroxyethyl propargyl ether (PME), 1-5 mg / L of N, N-diethyl propargyl amine (DEP), 1- 5mg / L sodium saccharin.

[0020] Use a 1L beaker as a plating tank, prepare additives A and B according to the proportion, and heat it to the working temperature for trial plating. During the electroless nickel plating process, 0.5-1.0mL / L of additives A and B were added each cycle.

[0021] In this embodiment, a galvanized iron sheet is used as a test piece, and its size is 50mm x 100mm x 0.5mm.

[0022] The process flow of elect...

Embodiment 2

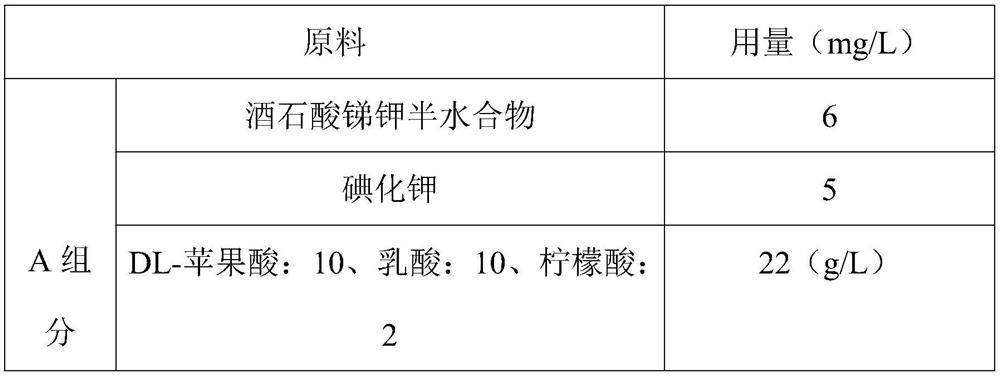

[0027] Recipe and operating conditions are as follows: nickel sulfate 24g / L, sodium hypophosphite 31g / L, the raw material composition of environmental protection type high phosphorus electroless nickel plating additive is as shown in table 1:

[0028] Table 1: Raw material composition of environmentally friendly high-phosphorus electroless nickel plating additives

[0029]

[0030]

Embodiment 3

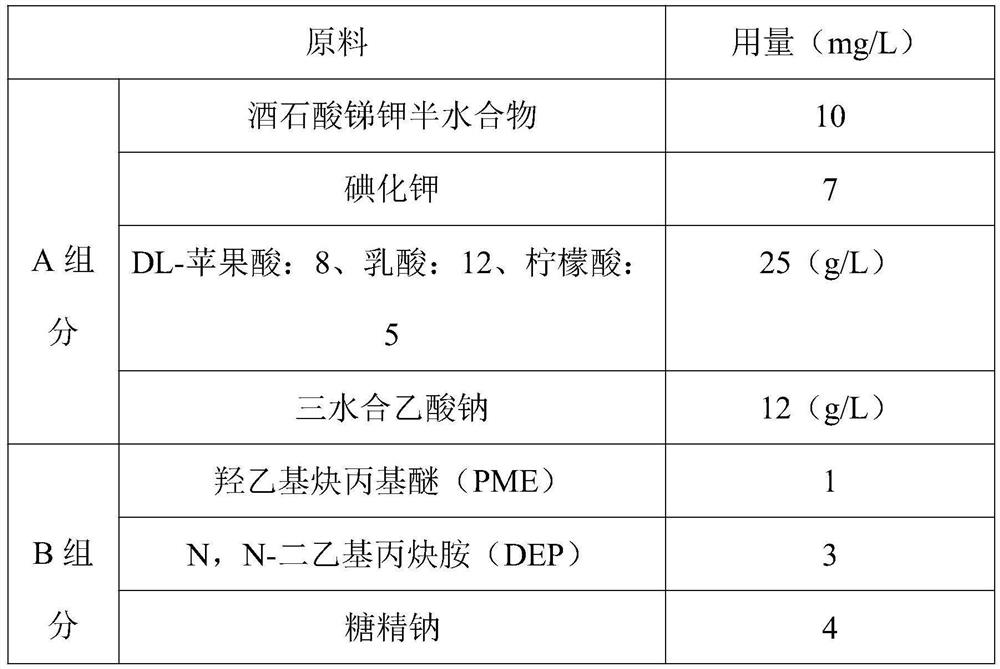

[0032] Recipe and operating conditions are as follows: nickel sulfate 25g / L, sodium hypophosphite 30g / L, the raw material composition of environment-friendly type bright high phosphorus electroless nickel plating additive is as shown in table 2:

[0033] Table 2: Raw material composition of environmentally friendly high-phosphorus electroless nickel plating additives

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com