Silicone rubber for composite insulator and preparation method of silicone rubber

A technology of composite insulator and silicone rubber, applied in the field of insulating materials, can solve the problems of poor nitric acid resistance, poor mechanical properties of high-temperature vulcanization modified silicone rubber, complicated preparation process, etc., and achieves good electrical corrosion resistance and easy quality control. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

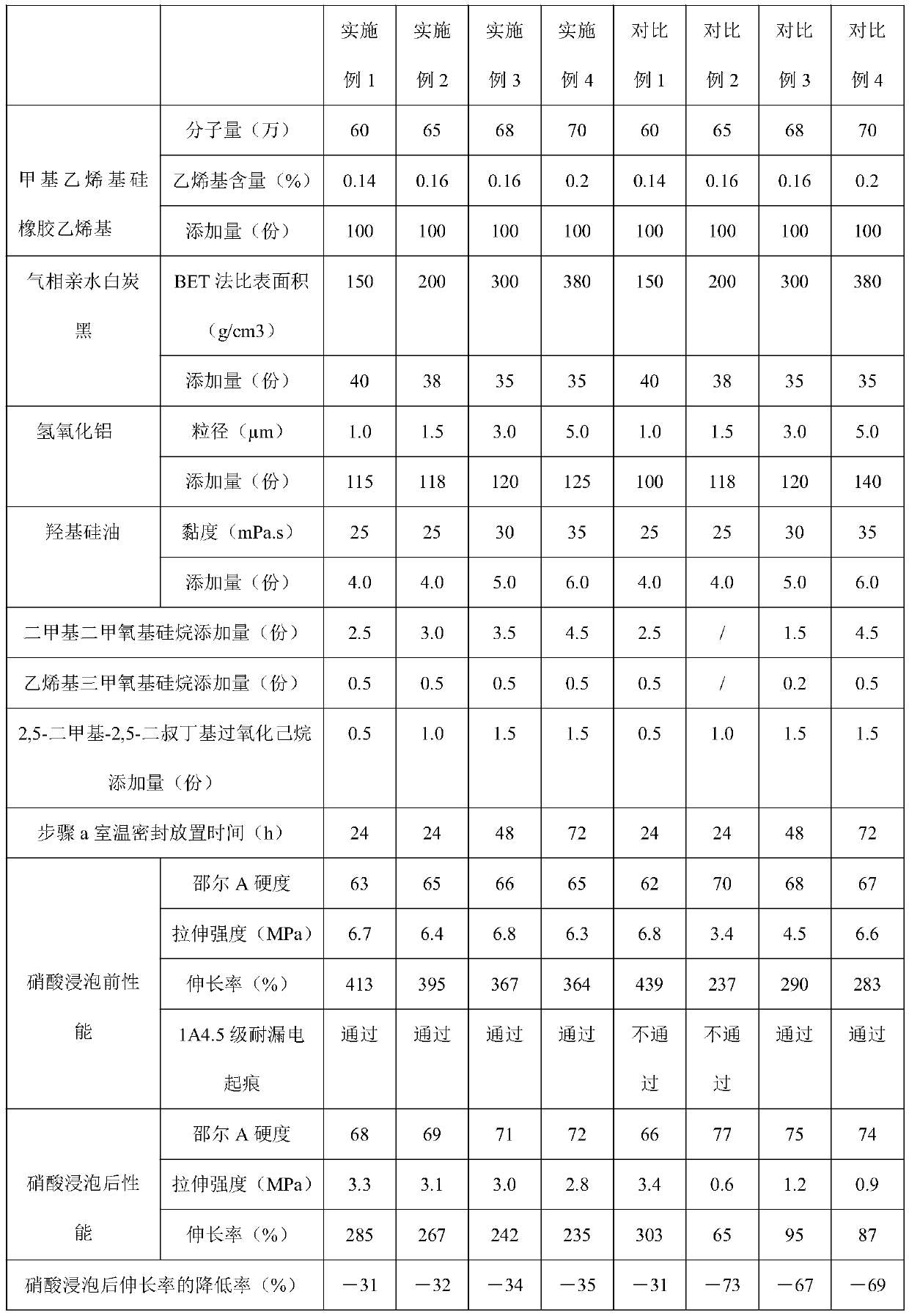

Examples

Embodiment 1

[0030] The components in parts by mass are as follows: 100 parts of methyl vinyl silicone rubber with a molecular weight of 600,000 and a vinyl content of 0.14%, and a BET method comparison area of 150m 2 40 parts / g of gas-phase hydrophilic silica, 115 parts of aluminum hydroxide with a particle size of 1.0 μm, 4.0 parts of hydroxy silicone oil with a viscosity of 25mPa.s, 2.5 parts of dimethyldimethoxysilane, vinyltrimethoxy 0.5 parts of silane, 0.5 parts of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane.

[0031] The preparation method of silicone rubber for composite insulators is as follows:

[0032] a. Firstly disperse 115 parts of aluminum hydroxide, 2.5 parts of dimethyldimethoxysilane and 0.5 part of vinyltrimethoxysilane with a high-speed disperser, and place it sealed at room temperature for 24 hours;

[0033] b. Then add 100 parts of methyl vinyl silicone rubber, 40 parts of white carbon black and 4.0 parts of hydroxy silicone oil into the kneader to knead at low tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com