Catalyst for FCC regeneration flue gas denitration, preparation method and application thereof

A technology for regeneration of flue gas and catalyst, which is applied in the field of FCC regeneration flue gas denitrification, preparation, and catalyst for FCC regeneration flue gas denitrification. The effect of short preparation cycle, high resistance to dust erosion, and wide active temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of Example 1 Mn-loaded cerium-titanium bimetallic composite oxide catalyst (Ce / Ti=0.3)

[0051] First, 10 g of tetrabutyl titanate was added into 30 ml of absolute ethanol, stirred thoroughly, and recorded as solution A. Subsequently, 0.3817 g of cerium nitrate was weighed and dissolved in a mixed solution of 1 ml of deionized water and 10 ml of absolute ethanol, which was designated as solution B. After mixing solutions A and B, stir thoroughly for 60-120 minutes, then add concentrated hydrochloric acid dropwise to the above solution, adjust the pH value to 1, continue stirring for 60-120 minutes, and then transfer the uniformly stirred solution to the surface After aging in the air for 18-48 hours in a dish, it was dried at 100°C for 12 hours and calcined at 500°C for 4 hours to obtain a cerium-titanium bimetallic composite oxide carrier.

[0052] Weigh 4g of the above-prepared cerium-titanium bimetallic composite oxide support and place it in an oven at ...

Embodiment 2

[0055] Preparation of Example 2 Fe-loaded cerium-titanium bimetallic oxide catalyst (Ce / Ti=0.3)

[0056] The synthesis steps of the cerium-titanium bimetallic composite oxide support are the same as in Example 1.

[0057] Weigh 4g of the above-prepared cerium-titanium bimetallic composite oxide carrier and place it in an oven at 80°C for 6 hours, then weigh 0.5787g of ferric nitrate to prepare aqueous solution C, and then add solution C dropwise to the dried and In the above materials that have been cooled, add them dropwise while stirring, then transfer them to a muffle furnace after ultrasonication and drying, and raise the temperature to the target temperature of 500 °C at a rate of 2 °C / min, and keep the temperature at this temperature for 6 hours to obtain FCC regeneration flue gas denitrification catalyst.

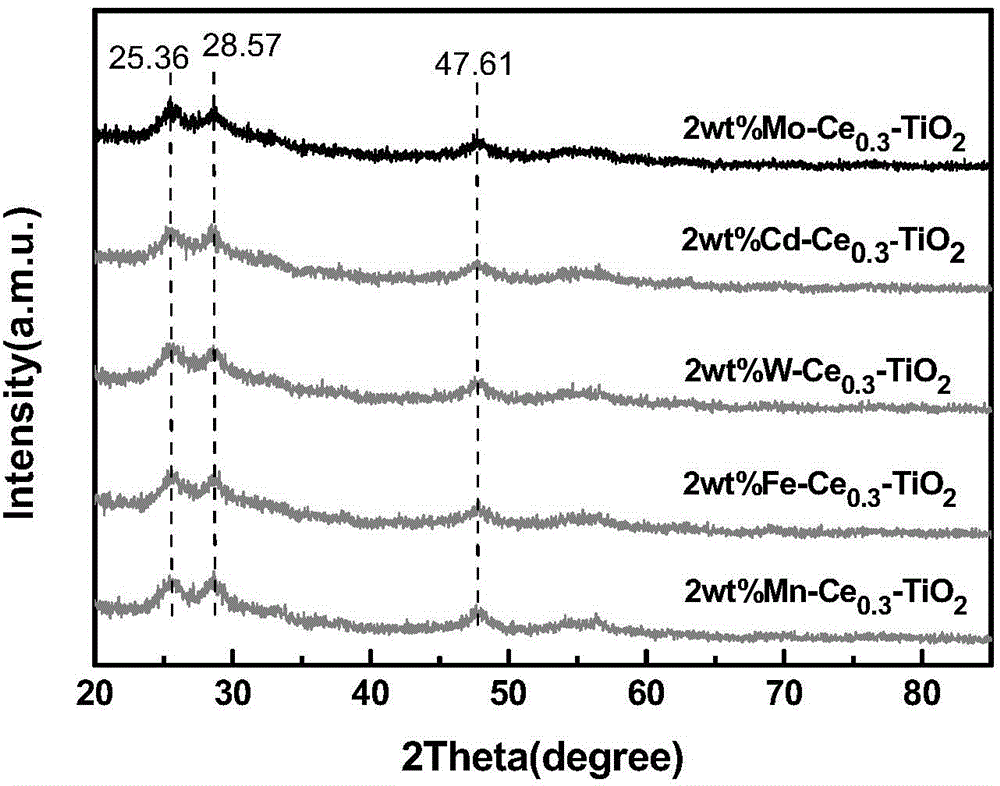

[0058] XRD characterization was carried out on the prepared FCC regeneration flue gas denitrification catalyst, and its XRD spectrum is as follows figure 1 Shown; ...

Embodiment 3

[0059] Preparation of Example 3 Mo-loaded cerium-titanium bimetallic oxide catalyst (Ce / Ti=0.3)

[0060] The synthesis steps of the cerium-titanium bimetallic composite oxide support are the same as in Example 1.

[0061] Weigh 4g of the above-prepared cerium-titanium bimetallic composite oxide support and place it in an oven at 80°C for 6 hours to dry, then weigh 0.1472g of ammonium molybdate to make aqueous solution C, and then add solution C dropwise to the dried And the above materials that have been cooled, are added dropwise while stirring, and then transferred to a muffle furnace after being ultrasonically dried and raised to a target temperature of 500°C at a heating rate of 2°C / min, and kept at this temperature for 6 hours. A catalyst for FCC regenerated flue gas denitrification is obtained.

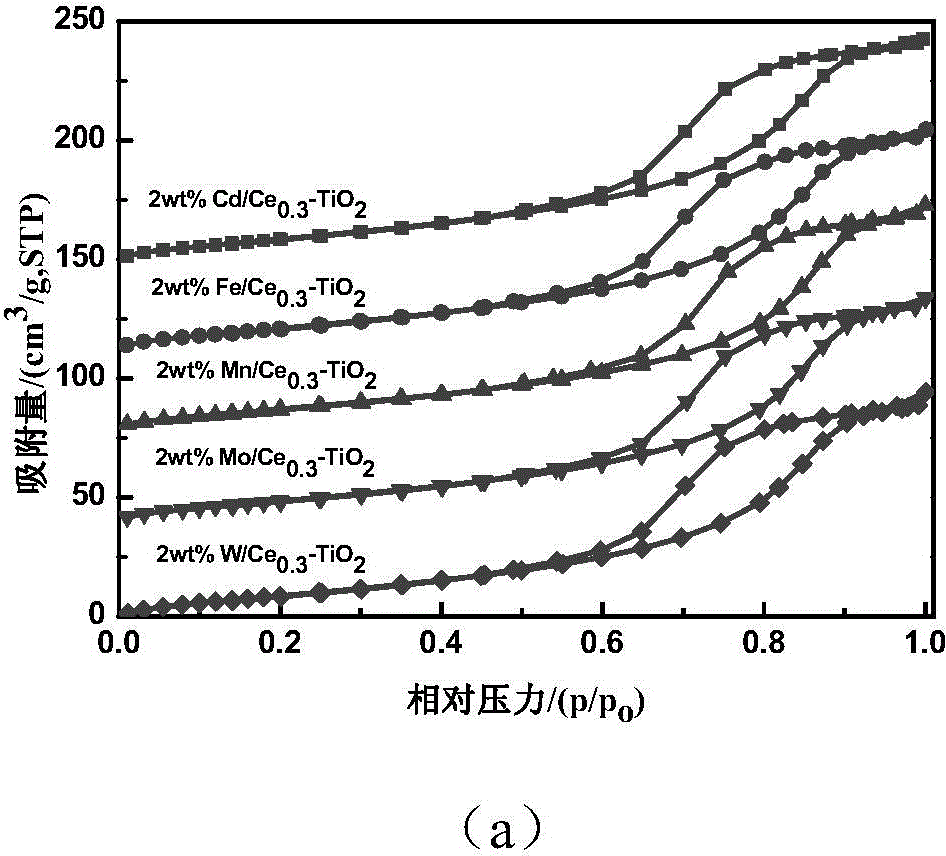

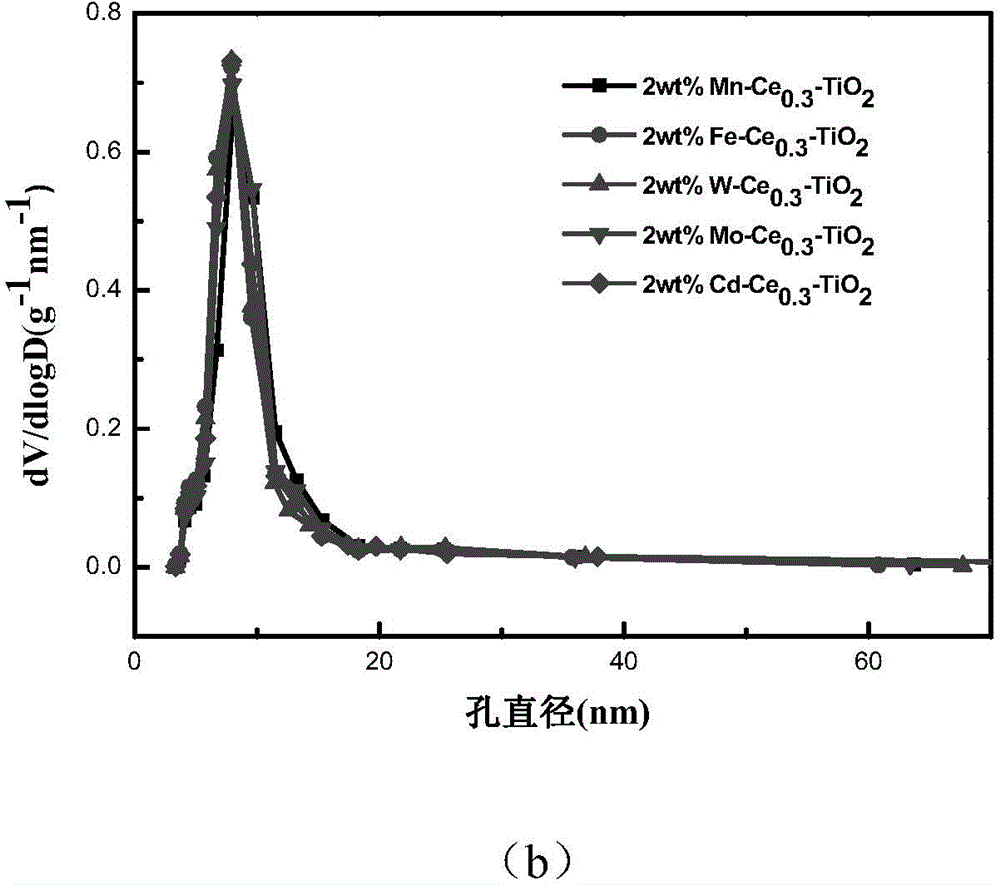

[0062] XRD characterization was carried out on the prepared FCC regeneration flue gas denitrification catalyst, and its XRD spectrum is as follows figure 1 Shown; BET characte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com