Preparation method of Ce-Li-MOF lithium ion battery negative electrode material and application in lithium ion battery preparation thereof

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, electrolyte battery manufacturing, secondary batteries, etc., and can solve problems such as rare electrochemical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of Ce-Li-MOF lithium-ion battery negative electrode material is implemented according to the following steps:

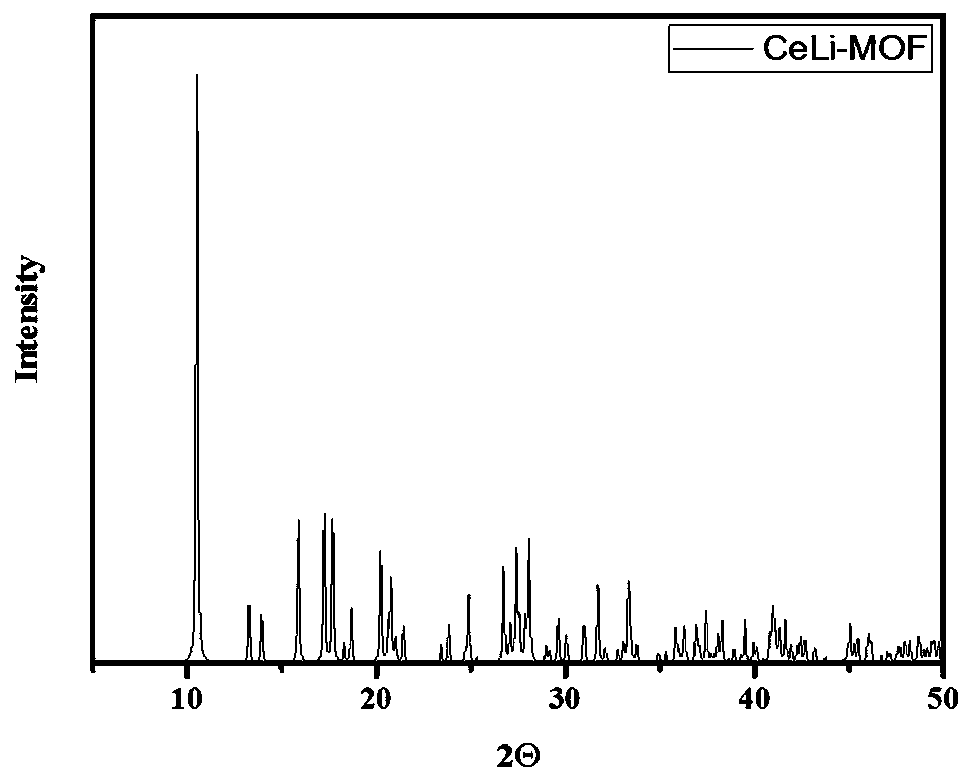

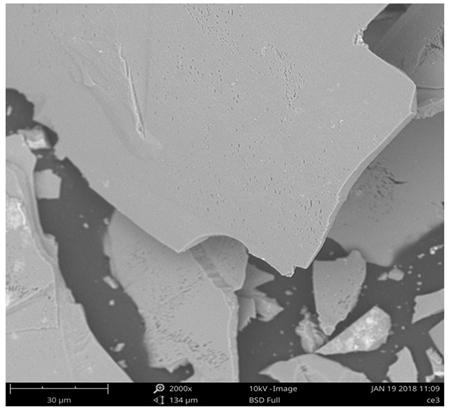

[0031] Step 1: pyromellitic acid (0.5032g), Ce(SO 4 ) 2 ˑ4H 2 O (0.7875g) and LiOH (0.2476g) were loaded into a polytetrafluoroethylene reactor, then 18.05g of deionized water was added, stirred at room temperature for 30 minutes, then the reactor was sealed and transferred to a preheated 200 ℃ oven, 200 ℃ constant temperature 72h. The oven was naturally cooled to room temperature, the solid product was rinsed with deionized water (100 mL) three times and ultrasonically cleaned, and then filtered to obtain light yellow crystalline particles, which were dried under natural environmental conditions to obtain Ce-Li-MOF materials.

[0032]Step 2: The application of the above-mentioned Ce-Li-MOF lithium-ion battery negative electrode material in the preparation of lithium-ion batteries is implemented as follows: the electrode active materi...

Embodiment 2

[0035] The preparation method of Ce-Li-MOF lithium-ion battery negative electrode material is implemented according to the following steps:

[0036] Step 1: pyromellitic acid (0.5905g), Ce(SO 4 ) 2 ˑ4H 2 O (0.7908g) and LiOH (0.2506g) were loaded into a polytetrafluoroethylene reactor, then 19.07g of deionized water was added, stirred at room temperature for 30 minutes, then the reactor was sealed and transferred to a preheating 190 ℃ oven, 190 ℃ constant temperature 71h. The oven was naturally cooled to room temperature, the solid product was rinsed with deionized water (100 mL) three times and ultrasonically cleaned, and then filtered to obtain light yellow crystalline particles, which were dried under natural environmental conditions to obtain Ce-Li-MOF materials.

[0037] Step 2: The application of the above-mentioned Ce-Li-MOF lithium-ion battery negative electrode material in the preparation of lithium-ion batteries is implemented as follows: the electrode active mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com