Plating solution formula of lead tin plating process for electronic components and lead tin plating process

A technology of electronic components and lead wires, which is applied in the field of copper wire or copper-clad steel wire tin plating process, and the plating solution formulation field of copper wire or copper-clad steel wire tin plating process, which can solve the problem of poor resistance to neutral salt spray, tin Short circuit of components, poor product appearance and other problems, to achieve low porosity, not easy to flow tin, and strengthen the effect of oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

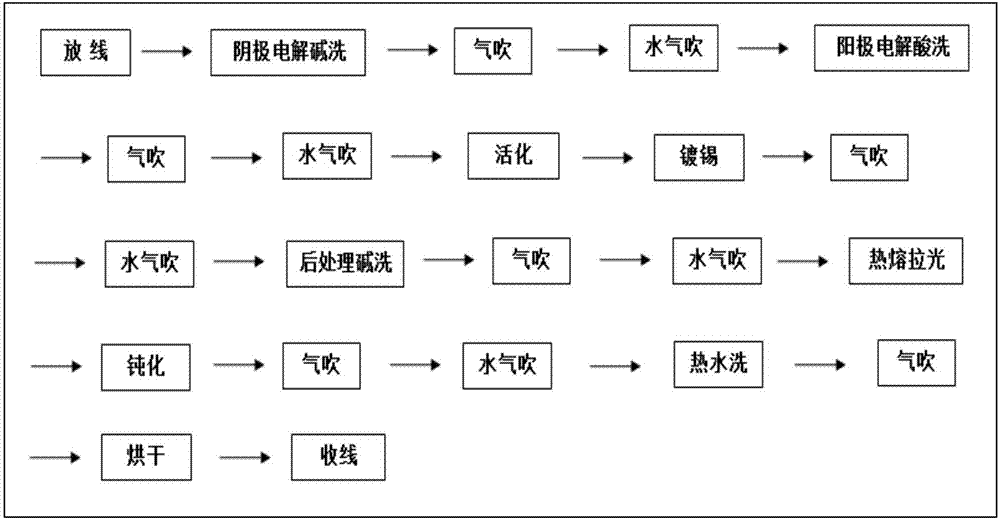

[0062] Such as figure 1 , the lead tin plating process of the plating solution, the lead wire (copper wire or copper-clad steel wire) is uniformly and continuously carried out in the following steps:

[0063] 1] Pre-treat the leads to expose the metal lattice:

[0064] 1.1] Pay-off: Use the active rotating pay-off reel to guide the rotation of the spool;

[0065] 1.2] Cathodic electrolytic alkali cleaning: through the electrolysis of the lead wire in the alkali cleaning tank, a large number of air bubbles are generated on the surface of the lead wire, and the air bubbles play an electrolytic stripping effect on the oil stain on the lead wire surface;

[0066] 1.3] Air blowing: Blow off the excess electrolytic lye brought out from the surface of the lead wire;

[0067] 1.4] Water and air blowing: clean the lye on the surface of the lead wire and blow off the cleaning water brought out;

[0068] 1.5] Anode electrolytic pickling: the lead wire after alkali cleaning is introduc...

Embodiment 2

[0108] Example 2: The effect of tinned copper wire produced by different plating solution formulas and the stability of the plating solution are compared

[0109] The plating solution in the tin plating tank is prepared according to the following formula, and the rest of the conditions are the same:

[0110]

[0111]

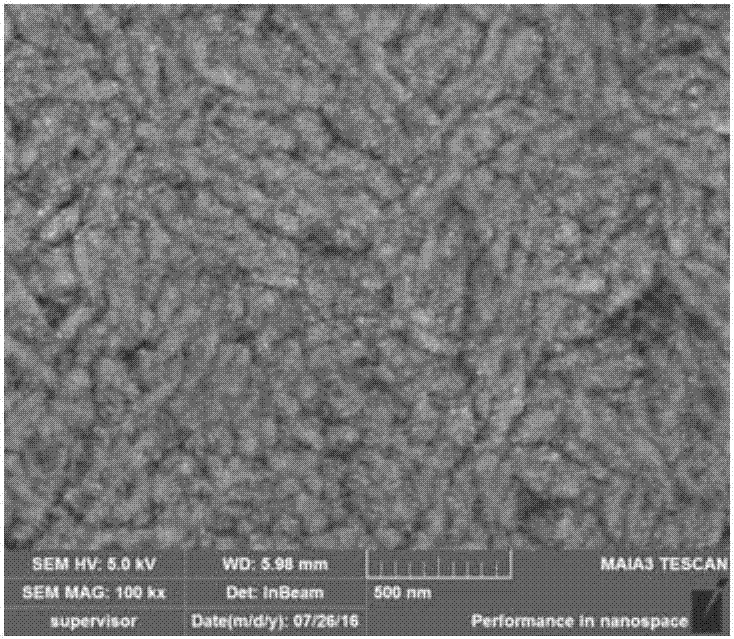

[0112] Tin-plated copper wire is produced according to formulas 1 to 5, and the microscopic SEM electron microscope picture of the tin layer surface of the resulting tin-plated copper wire is as follows Figure 3a shown in bcde.

[0113] In the plating solution formula, in order to prevent divalent tin from being oxidized to tetravalent tin and improve the stability of the plating solution, sodium hypophosphite, ascorbic acid, polyethylene glycol, and catechol are used together as divalent tin stabilizers. Give full play to the strong reducing properties of sodium hypophosphite. Sodium hypophosphite is generally used in electroless plating. When it is use...

Embodiment 3

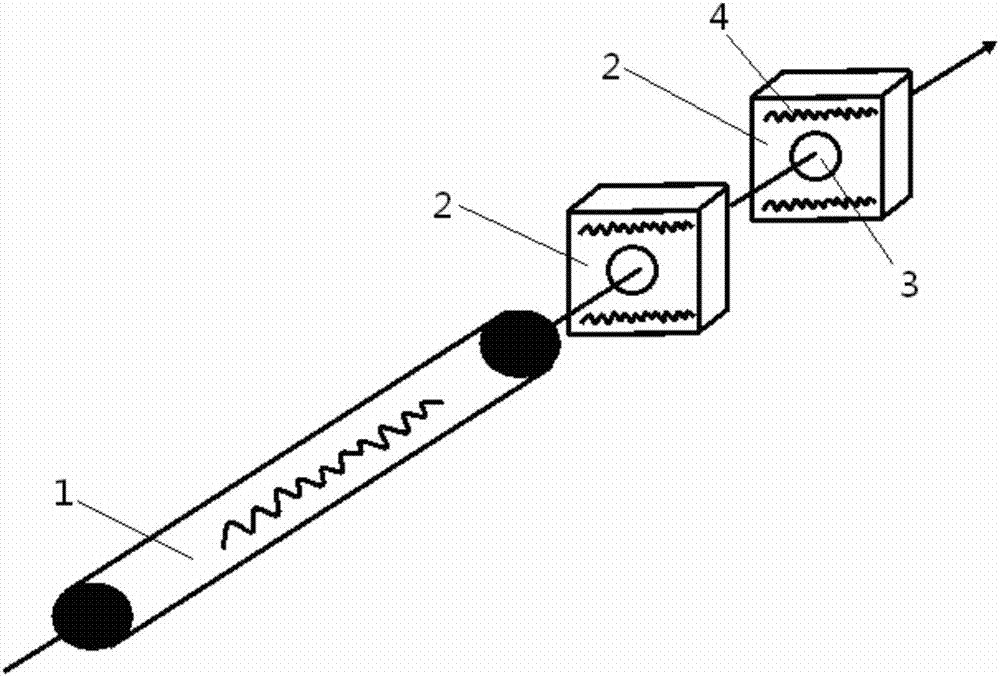

[0116] Example 3: Verifying the influence of the hot-melt pulling step on the effect

[0117] According to formula one among the embodiment one, tinned copper wire is produced, Figure 4a It is the 300 times mirror SEM electron microscope picture of the tinned copper wire obtained by lubricant cold polishing, Figure 4b It is the 300 times mirror SEM electron microscope picture of the tinned copper wire obtained by hot melt drawing, Figure 5a It is the 2000 times mirror SEM electron microscope image of the tinned copper wire obtained by lubricant cold polishing, Figure 5b It is the 2000 times SEM electron microscope image of the tinned copper wire obtained by hot-melt drawing.

[0118] From the microscopic comparison of the scanning electron microscope, under the same mold pulling conditions, the microscopic surface of the coating of the lubricant cold-polished lead has many pores, depressions and cracks, while the microscopic surface of the coating of the lead drawn by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com