Preparation method of defluorination adsorbent based on flour

An adsorbent, flour technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. High performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Effect of the volume ratio of methane and argon on the adsorption performance of the prepared fluorine removal adsorbent

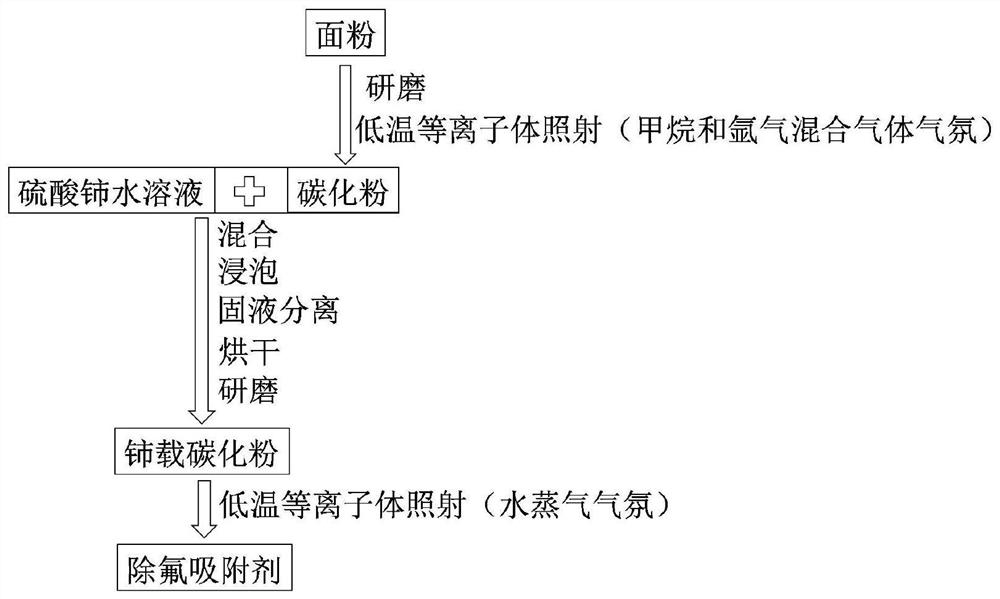

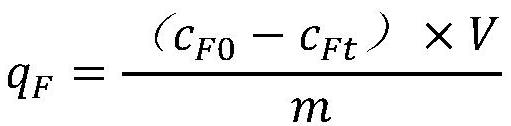

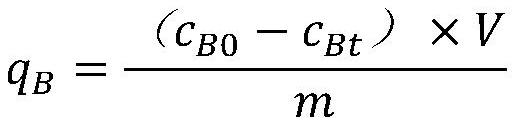

[0019] Preparation of fluorine-removing adsorbent: as figure 1 As shown, the flour is ground for 1 hour, and then subjected to low-temperature plasma irradiation for 1 hour to obtain carbonized powder, wherein the applied voltage of low-temperature plasma irradiation is 3kV, and the operating atmosphere is a mixed gas of methane and argon, and the volume ratio of methane and argon is 2.5:100, 3.5:100, 4.5:100, 5:100, 15:100, 25:100, 26:100, 28:100, 30:100; Dissolve cerium sulfate in water to prepare 20g / L cerium sulfate Aqueous solution, according to the solid-to-liquid ratio of carbonized powder and cerium sulfate aqueous solution 0.4:1 (g:mL), mix carbonized powder and cerium sulfate aqueous solution, soak for 2 hours, separate solid from liquid, dry the solid at 50°C, and grind for 0.5 hour to obtain Cerium-loaded carbide powder; low-temperature...

Embodiment 2

[0027] Influence of Concentration of Cerium Sulfate Aqueous Solution on the Adsorption Performance of Prepared Fluorine Removal Adsorbent

[0028] Preparation of fluorine-removing adsorbent: Grind the flour for 2 hours, and then irradiate with low-temperature plasma for 2 hours to obtain carbonized powder. The volume ratio of argon is 25:100; dissolve cerium sulfate in water to prepare 10g / L, 15g / L, 18g / L, 20g / L, 40g / L, 60g / L, 62g / L, 65g / L, 70g / L cerium sulfate aqueous solution, according to the solid-to-liquid ratio of carbide powder and cerium sulfate aqueous solution 0.8:1 (g:mL), mix the carbonized powder and cerium sulfate aqueous solution, soak for 4 hours, separate the solid and liquid, and dry the solid at 100°C , grind for 1 hour to get cerium-loaded carbonized powder; irradiate cerium-loaded carbonized powder with low-temperature plasma for 2 hours to obtain fluorine-removing adsorbent, wherein the action voltage of low-temperature plasma irradiation is 16.5kV, and t...

Embodiment 3

[0035] Influence of Water Vapor Humidity on the Adsorption Performance of Prepared Fluoride Removal Adsorbent

[0036] Preparation of fluorine-removing adsorbent: Grind flour for 3 hours, and then irradiate with low-temperature plasma for 3 hours to obtain carbonized powder. The gas volume ratio is 25:100; dissolve cerium sulfate in water to prepare 60g / L cerium sulfate aqueous solution, and mix the carbonized powder and cerium sulfate aqueous solution according to the solid-to-liquid ratio of carbonized powder and cerium sulfate aqueous solution 1.2:1 (g:mL) , soaked for 6 hours, separated from solid and liquid, dried the solid at 150°C, and ground for 1.5 hours to obtain cerium-loaded carbide powder; irradiated cerium-loaded carbide powder with low-temperature plasma for 3 hours to obtain a fluorine-removing adsorbent, in which low-temperature plasma The irradiation voltage is 30kV, the action atmosphere is water vapor, and the water vapor humidity is 30%RH, 40%RH, 50%RH, 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com