Sealing treatment method used in aluminum alloy surface treatment and sealing liquid used thereby

A technology of aluminum alloy surface and sealing treatment, applied in the direction of surface reaction electrolytic coating, metal material coating process, electrolytic coating, etc., can solve the problem of unsatisfactory corrosion resistance of oxide film, achieve compact structure and improve corrosion resistance , the effect of uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0020] In this embodiment, the 7075 aluminum alloy after anodic oxidation is sealed, and the specific method is as follows:

[0021] First hang the 7075 aluminum alloy with anodized film on the surface after anodic oxidation.

[0022] Then it was hung and immersed in the blocking solution at 50°C for 60 minutes; the composition of the blocking solution was: 5 g / L of cerium sulfate tetrahydrate, 1 g / L of lanthanum nitrate hexahydrate, and 0.5 g / L of ammonium persulfate.

[0023] Finally, the 7075 aluminum alloy is taken out, washed with water and dried.

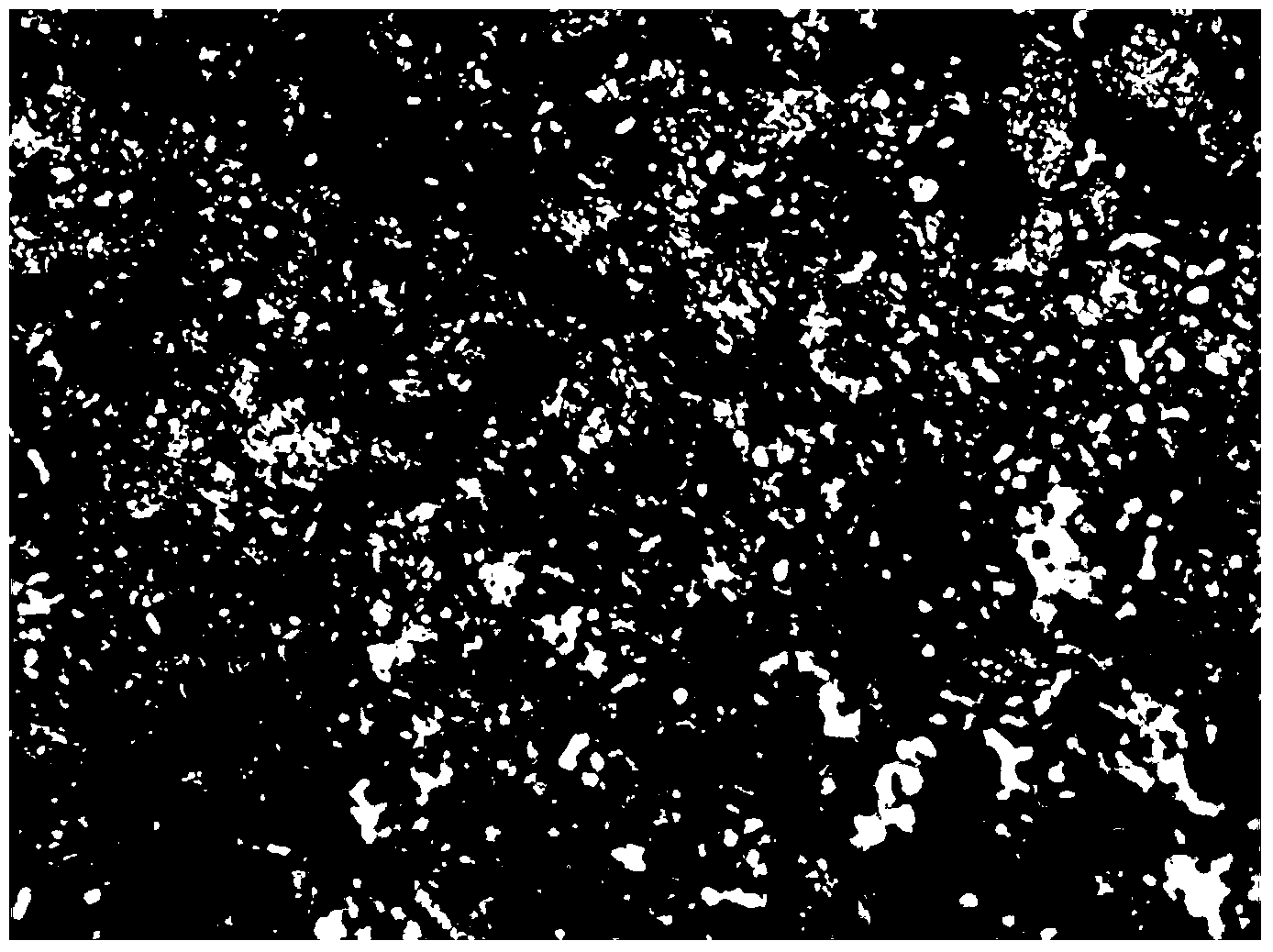

[0024] The metallographic microscope photo of the 7075 aluminum alloy surface after the sealing treatment of this embodiment is shown in figure 1 .

[0025] Depend on figure 1 It can be seen that the surface of the 7075 aluminum alloy after the sealing treatment in this embodiment is uniform, without iridescent color, dense in structure and non-porous.

[0026] The salt spray corrosion test and the spotting corrosion test ...

Embodiment 2~ Embodiment 5)

[0030] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0031] Table 1

[0032] Example 1 Example 2 Example 3 Example 4 Example 5 aluminum alloy 7075 aluminum alloy 7075 aluminum alloy 7075 aluminum alloy 7075 aluminum alloy 7075 aluminum alloy Cerium Sulfate 15g / L 5g / L 25g / L 15g / L 15g / L Lanthanum nitrate 3g / L 1g / L 5g / L 3g / L 3g / L Ammonium persulfate 1.5g / L 0.5g / L 2.5g / L 1.5g / L 1.5g / L Blocking fluid temperature 50℃ 50℃ 50℃ 40℃ 60℃ Soaking time 60min 60min 60min 70min 50min Salt spray resistance time 153h 149h 151h 152h 153h drip time 12.56s 12.49s 12.52s 12.51s 12.53s

Embodiment 6)

[0034] In this embodiment, the anodized 6063 aluminum alloy is sealed, and the specific method is the same as that in Embodiment 1.

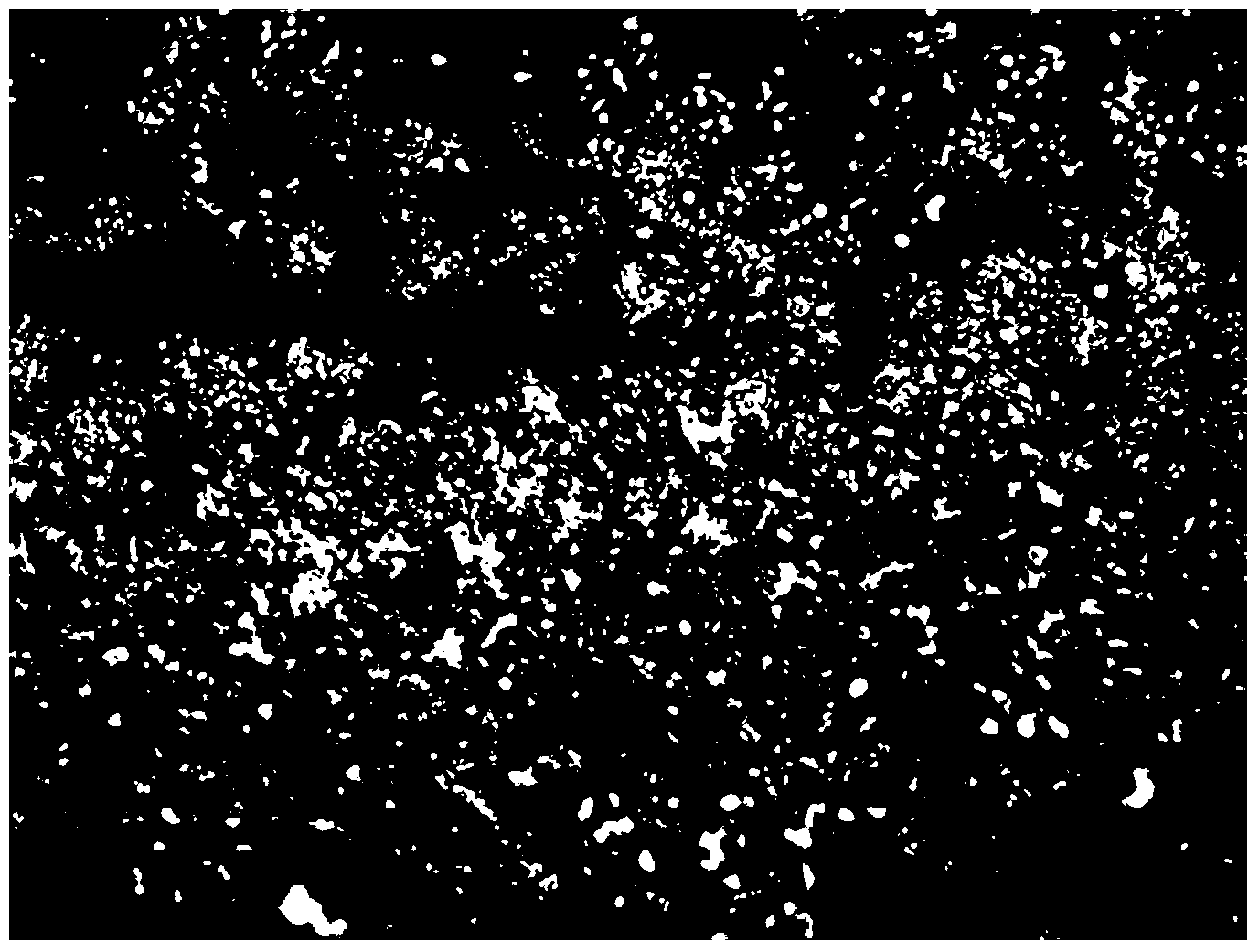

[0035] The metallographic microscope photo of the 6063 aluminum alloy surface after the sealing treatment of this embodiment is shown in figure 2 .

[0036] Depend on figure 2 It can be seen that the surface of the 6063 aluminum alloy after the sealing treatment in this embodiment is uniform, without iridescent color, dense in structure, and non-porous.

[0037] The salt spray corrosion test and the spotting corrosion test were carried out on the anodized film on the surface of the 6063 aluminum alloy after the sealing treatment in this embodiment, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com