Red rare-earth lanthanum cerium sulfide dye and preparation method thereof

A lanthanum sulfide and rare earth technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of poor stability and color performance of sulfur oxides, poor β-type structure, and sulfur deficiency, and achieve rich Effects of color and tint, lower synthesis temperature, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

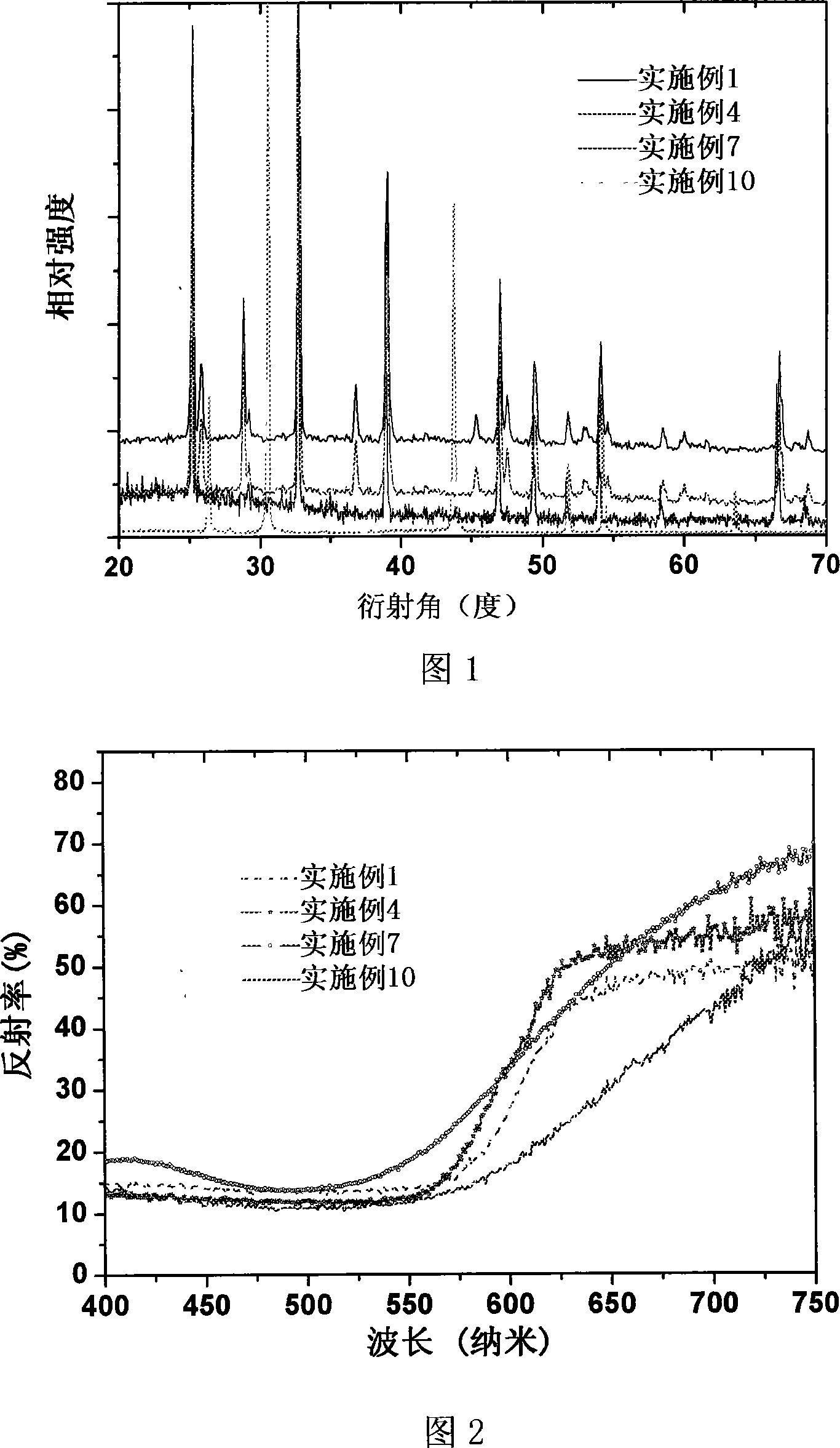

Embodiment 1

[0039] According to the chemical structural formula of the product is Na 0.2 CeS 1.6 The molar content of various metal raw materials and the total amount of raw materials are 500 grams to weigh the raw materials, mix and stir the raw materials sodium bicarbonate, rare earth lanthanum oxide and rare earth cerium oxide, then put them into the reaction boat, and then put them into the tube furnace In the closed reaction furnace, the inert gas is high-purity nitrogen, and the gas flow rate is 0.1 liters / minute. After 10 minutes, the sulfur source gas generated by heating, melting and decomposing ammonium thiocyanate is introduced, and then the heating rate is 10 ℃ / minute. , raise the temperature of the high-temperature tubular reactor to 700°C, and keep it at this temperature for 3h. Continue to pass sulfur source gas and inert gas, and then continue to heat up to 900°C with a heating rate of 10°C / min, and keep at this temperature for 2h. Then stop heating and pass sulfur source ...

Embodiment 2

[0045] Rare earth raw material adopts cerium carbonate, others are the same as embodiment 1. A red product was obtained. Its structure is Th in the cubic γ-type structure 3 P 4 crystal phase. CIE color coordinates are: L * =50.082,a * =23.379,b * = 14.492.

Embodiment 3

[0047] The raw material of the alkali metal is anhydrous sodium carbonate, and the inert gas is high-purity argon. Others are the same as in Example 1, and a red product is obtained. Its structure is Th in the cubic γ-type structure 3 P 4 crystal phase. CIE color coordinates are: L * =50.082,a * =23.379,b * = 14.492.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com