Ceramic and preparation method and application thereof

A ceramic and oxide technology, applied in the field of structural ceramics, can solve the problems of difficult practical application of zirconia, easy to float above the material, reduce work efficiency, etc., and achieve the effects of rich colors, good thermal shock resistance, and reduced wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

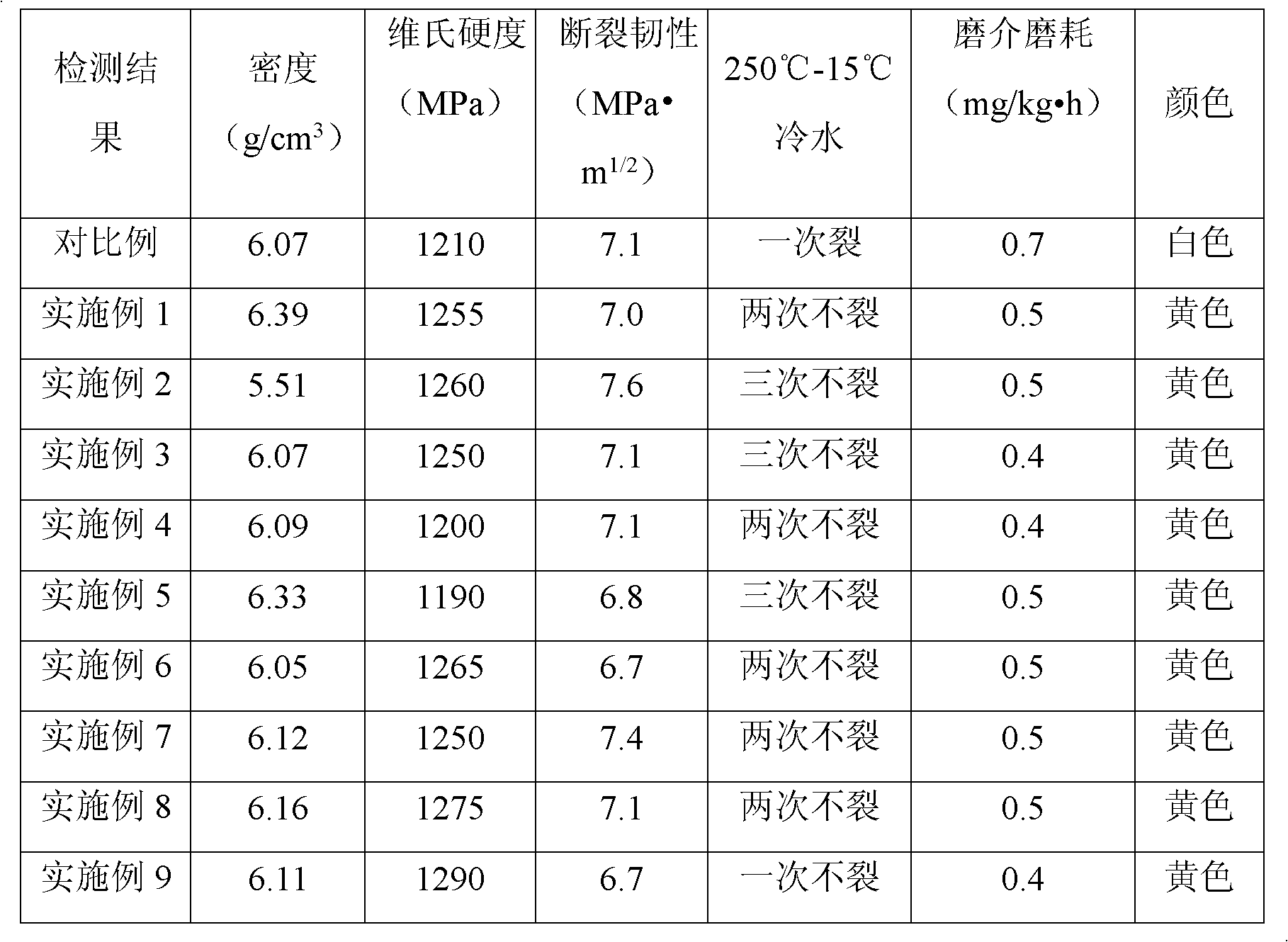

Examples

Embodiment 1

[0044] Ceramic granulating powder and ceramic knives are prepared from oxide powder materials as raw materials.

[0045] Step 1: Add each oxide and 800g of deionized water into a ball mill according to the ratio of Example 1 in Table 1, and mix uniformly to obtain slurry one;

[0046] Step 2: Add 167g of PVA and 11g of carboxymethylcellulose to slurry one and continue ball milling to obtain slurry two;

[0047] Step 3: Granulate the second slurry to obtain ceramic granulated powder;

[0048] Step 4: Dry the ceramic granulated powder prepared in Step 3 into a hydraulic press, and then perform isostatic pressing together with the molded body obtained in the comparative example to obtain a ceramic knife green body;

[0049] Step 5: Debinding the ceramic knife green body and the green body obtained in the comparative example in the same furnace and sintering at 1305°C to form a ceramic knife blank;

[0050] Step 6: Then the ceramic knife blank is ground, shaped, sharpened, and polished to ob...

Embodiment 2

[0052] Preparation of ceramic powder and ceramic knife with yttrium zirconium ceramic powder and other oxides as raw materials:

[0053] Step 1: Add 617g of yttrium-zirconium ceramic granulated powder (Y2O35.5wt% and ZrO294.5wt% in terms of oxides), 81g of yttrium oxide and other oxides in Example 2 of Table 1 and 900g of deionized water into a ball mill to obtain a ball mill. Slurry one; the yttrium-zirconium ceramic granulated powder is a mixture of yttrium oxide and zirconium oxide obtained by firing yttrium zirconium hydroxide and then pulverized and spray-granulated powder;

[0054] Step 2: Add 125g of PVA, 10.5g of CMC and 15g of polyacrylic acid to slurry one and continue ball milling to obtain slurry two;

[0055] Step 3: Input the second slurry into a spray granulator for spray granulation to obtain ceramic granulated powder;

[0056] Step 4: Dry the ceramic granulated powder produced in Step 3 on a hydraulic press to form a green ceramic knife, and then subject it to isostat...

Embodiment 3

[0060] Preparation of ceramic powder and ceramic grinding pot with yttrium zirconium ceramic precursor and other oxides as raw materials:

[0061] Step 1: Add the yttrium zirconium ceramic precursor (containing Y 2 O 3 10g, ZrO 2 659g), other oxides, and deionized water are added to the ball mill and ball milled into slurry 1. The weight of deionized water is 950g; the yttrium-zirconium ceramic precursor is yttrium element and zirconium element obtained by co-precipitation of yttrium hydroxide and zirconium hydroxide mixture;

[0062] Step 2: After drying slurry 1, add 121g of PVA and 150g polymaleic acid to continue ball milling to obtain slurry 2;

[0063] Step 3: Input the second slurry into a spray granulator for spray granulation to obtain ceramic granulated powder;

[0064] Step 4: Dry pressing the ceramic granulated powder obtained in Step 3 to obtain a green ceramic grinding pot;

[0065] Step 5: After debinding, the green ceramic grinding pot is sintered into a ceramic grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com