Production method of imitated natural marble polished glazed brick

A technique for marble and glazed tiles is applied in the field of preparation of imitation natural marble polished glazed tiles, which can solve the problems of weak three-dimensional effect of patterns, bottom penetration, and low hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method for imitating natural marble glazed tiles, comprising the steps of:

[0026] (1) adopt known body raw material and colorant to mix, granulate and make granular colored powder;

[0027] (2) Mixing the colored powder and known green body powder into cloth, and then stamping to form a ceramic brick adobe with decorative texture throughout;

[0028] (3) distributing transparent glaze on the adobe obtained in step (2);

[0029] (4) Go into the kiln for firing and polishing to obtain glazed tiles imitating natural marble.

[0030] Here, the green body raw material is mixed with the colorant, and granulated to make granular colored powder; it is mixed with the known green body powder, and the texture formed runs through the entire green body, and the fired brick has The whole body has a decorative effect, so there will be no bottom-through phenomenon during the polishing and cutting process. In addition, in step 1, there are two ways to mix the known gr...

Embodiment 1

[0059] Embodiment 1: a kind of preparation method of imitation natural marble glazed tile with oozing effect:

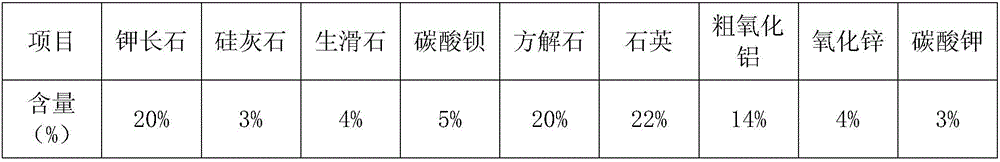

[0060] A transparent glaze is provided, which is composed of frit and raw material, and its raw material ratio includes the following components according to the mass fraction:

[0061]

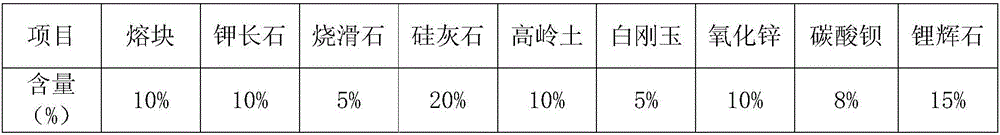

[0062] The mineral raw material ratio of the frit includes the following components according to the mass fraction:

[0063]

[0064] The frit melting temperature is 1450°C.

[0065] Its preparation process is as follows:

[0066] A method for preparing imitation natural marble glazed tiles with bleeding effect, comprising the following steps:

[0067] (1) adopt known green body raw material, add the colorant spray granulation to make and the colored powder of two colors;

[0068] (2) Mix the colored powder with the known green body powder; there are many ways to choose the cloth, such as multi-tube magic cloth, cloth with engraved drum or carved belt, and dislocation mixed...

Embodiment 2

[0075] Embodiment 2: a kind of preparation method of imitation natural marble glazed tile with sunken texture:

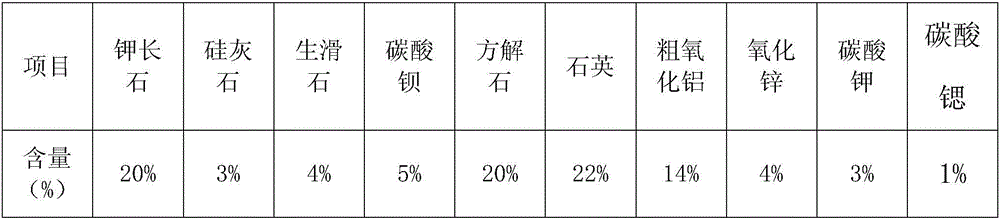

[0076] A transparent glaze is provided, which is composed of frit and raw material, and its raw material ratio includes the following components according to the mass fraction:

[0077]

[0078] The mineral raw material ratio of the frit includes the following components according to the mass fraction:

[0079]

[0080] The melting temperature of the frit is 1500°C.

[0081] A preparation method of imitation natural marble glazed brick with sunken texture, comprising the steps of:

[0082] (1) adopt known green body raw material, add the coloring material spray granulation and make the colored powder material with three kinds of colors;

[0083] (2) Mix the colored powder with the known green body powder; there are many ways to choose the cloth, such as multi-tube magic cloth, cloth with engraved drum or carved belt, and dislocation mixed cloth with conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com