Transition paint for easy-lifting paint film surface as well as preparation method and coating method of transition paint

A technology of film surface and transition paint, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, which can solve the problems of not easy to take off, harm to operators, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with embodiment the present invention will be further described:

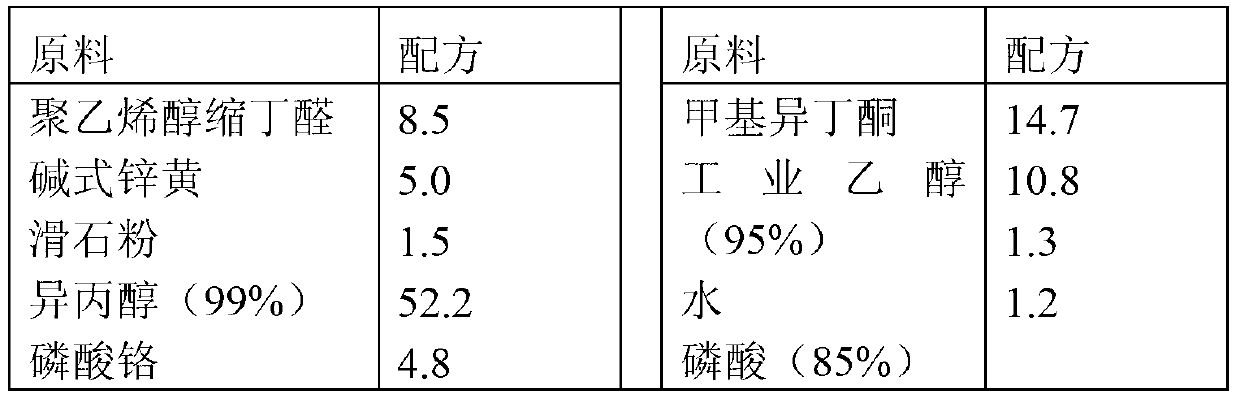

[0021] Formula (mass%)

[0022]

[0023] When preparing, fill container 1 with polyvinyl butyral, add isopropanol (99%) and stir evenly; fill container 2 with phosphoric acid (85%), add industrial ethanol (95%) and stir evenly; Then mix the solutions in containers 1 and 2 and add other substances, and stir evenly.

[0024] Coating:

[0025] Step 1: Use cotton yarn dipped in ethyl acetate or solvent gasoline to wipe the surface of the original paint film to remove visible grease. Generally wipe 2 times.

[0026] Step 2: Dilute the paint to application viscosity with denatured alcohol. Use brushing, and adjust the construction viscosity to (Tu-4) 18-25 seconds (Tu-4 refers to the paint viscosity measured with a Tu-4 viscometer, see GB / T1723-93 Paint Viscosity Measurement Method, the same below). Apply by spraying. The construction viscosity is adjusted to (Tu-4) for 13-18 second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com