Organic-inorganic hybrid epoxy resin curing agent as well as preparation method and application thereof

A technology of epoxy resin curing and epoxy varnish, applied in epoxy resin coatings, organic chemistry, chemical instruments and methods, etc., can solve the problems of cumbersome operation, high safety risk, harsh conditions, etc., and achieve good storage stability, The effect of single process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

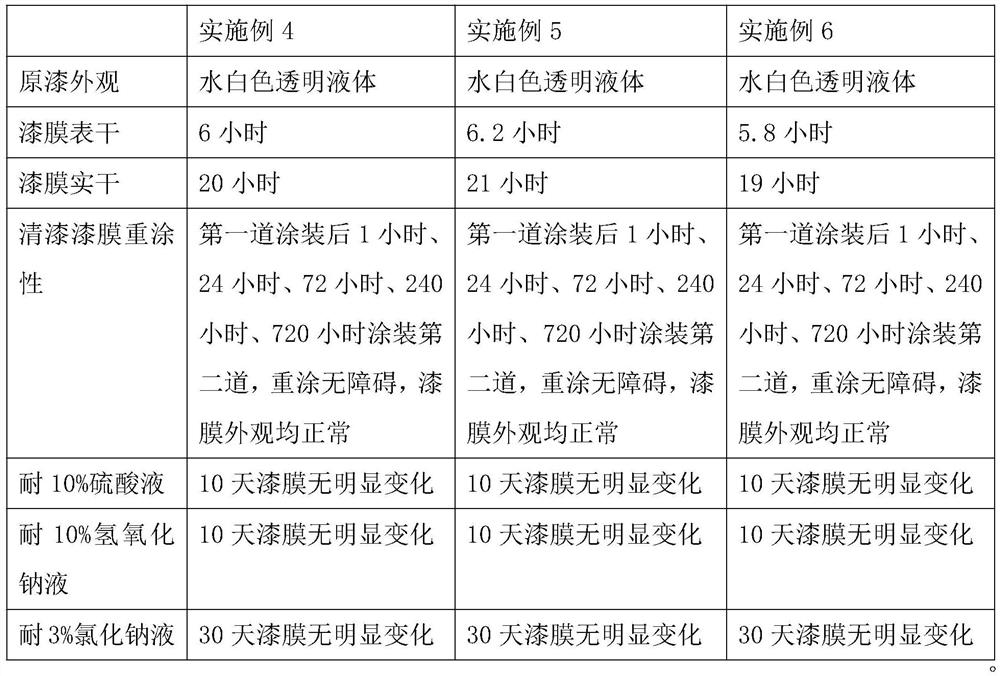

Examples

Embodiment 1

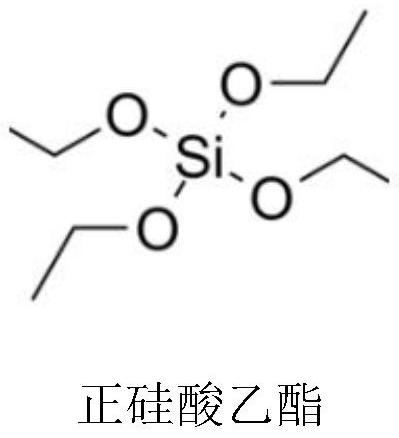

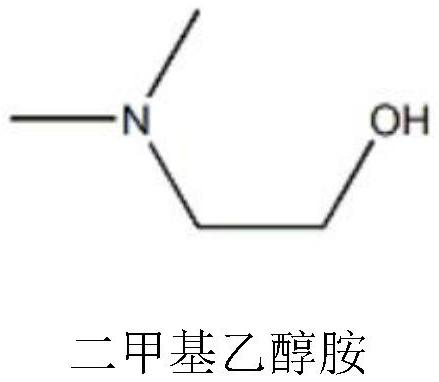

[0026] Weigh 780 grams of tetraethyl orthosilicate and 1220 grams of dimethylethanolamine into the reaction kettle, control and slowly heat to 120±2°C over 3 hours, and keep the temperature for 10 hours. The temperature is lowered to below 80°C, and the epoxy resin curing agent of the present invention is obtained immediately after being taken out of the pot.

Embodiment 2

[0028] Weigh 740 grams of tetraethyl orthosilicate and 1260 grams of dimethylethanolamine into the reaction kettle, control and slowly heat to 115° C. over 3 hours, and keep the temperature for 12 hours. The temperature is lowered to below 80°C, and the epoxy resin curing agent of the present invention is obtained immediately after being taken out of the pot.

Embodiment 3

[0030] Weigh 820 grams of tetraethyl orthosilicate and 1180 grams of dimethylethanolamine into the reaction kettle, control and slowly heat to 130° C. over 3 hours, and keep the temperature for 8 hours. The temperature is lowered to below 80°C, and the epoxy resin curing agent of the present invention is obtained immediately after being taken out of the pot.

[0031] The color, appearance and solid content test results of the epoxy resin curing agent of the present invention are shown in Table 1 below, wherein the solid content test conditions are as follows: 1 gram of sample is weighed and baked at 105° C. for 30 minutes.

[0032] Table 1 epoxy resin curing agent color of the present invention and appearance and solid content detection result

[0033] Example 1 Example 2 Example 3 color and appearance Water white transparent viscous liquid Water white transparent viscous liquid Water white transparent viscous liquid Solid content (%) 68.2 68.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com