Patents

Literature

43results about How to "Single process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

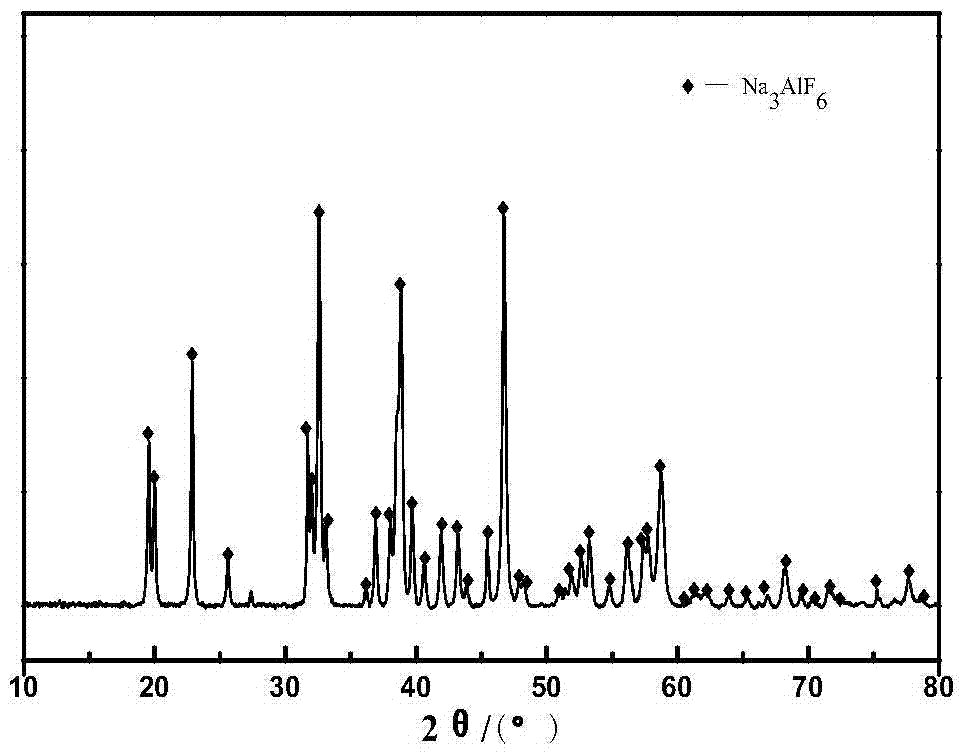

Harmlessness and reclamation treatment method of aluminum scrap electrolyte

ActiveCN108677020AEfficient decompositionSolve environmental problemsSulfate/bisulfate preparationAlkali metal nitrate preparationAluminum fluorideElectrolysis

The invention discloses a harmlessness and reclamation treatment method of aluminum scrap electrolyte and belongs to the technical field of inorganic chemistry. The method comprises the main steps that 1, aluminum scraps are electrolyzed and subjected to crushing and screening, and aluminum electrolyte particles are obtained; 2, acid liquor with the concentration of 1 mol / L and an aluminum salt solution with the concentration of 1 mol / L are prepared for standby application; 3, the aluminum electrolyte particles obtained in the step 1 are placed in the acid liquor prepared in the step 2 and leached on the heating and stirring conditions, the PH of the solution is controlled to be smaller than 5, when the fluorinion leaching rate is higher than 94%, leaching is finished, impurities are filtered, and a leaching solution is obtained; 4, the aluminum salt solution prepared in the step 2 is added to the leaching solution in the step 3, the mixture is heated and stirred, Al3+ / Na+ is controlled to be larger than 0.3, when sediment is generated in the solution, the solution is filtered, filter residues and filter liquor are obtained, and the filter residues are washed and dried to obtain alkali type aluminum fluoride products; and 5, the filter liquor in the step 4 is evaporated and crystallized to obtain sodium salt products.

Owner:NORTHEASTERN UNIV

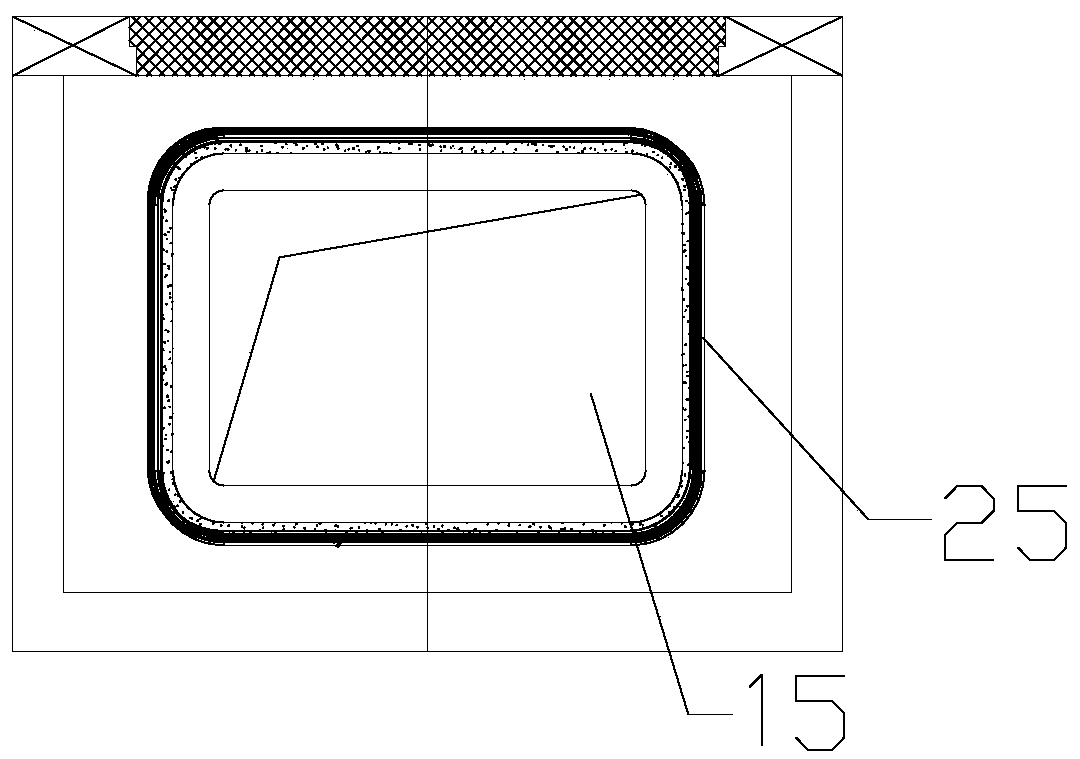

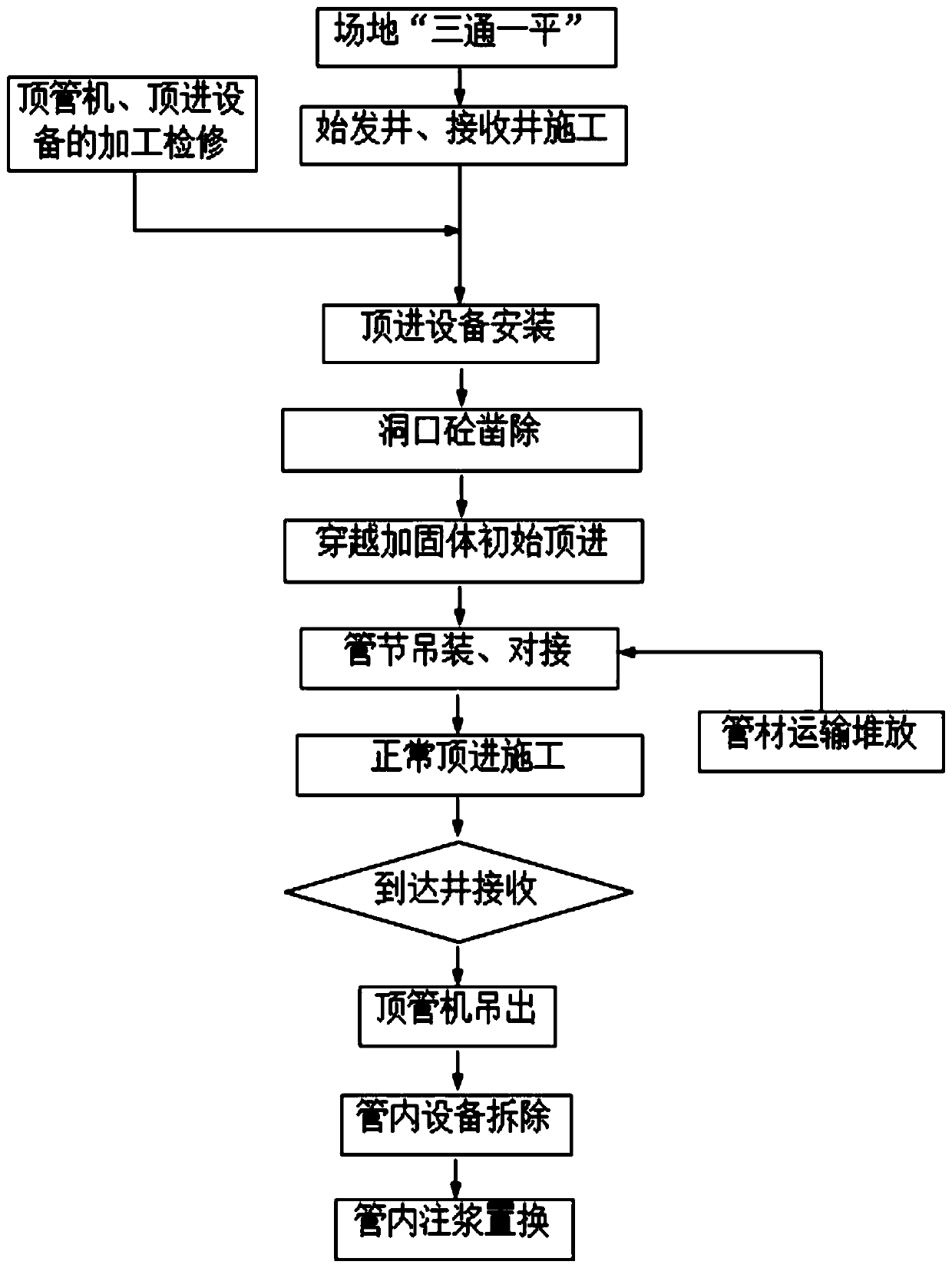

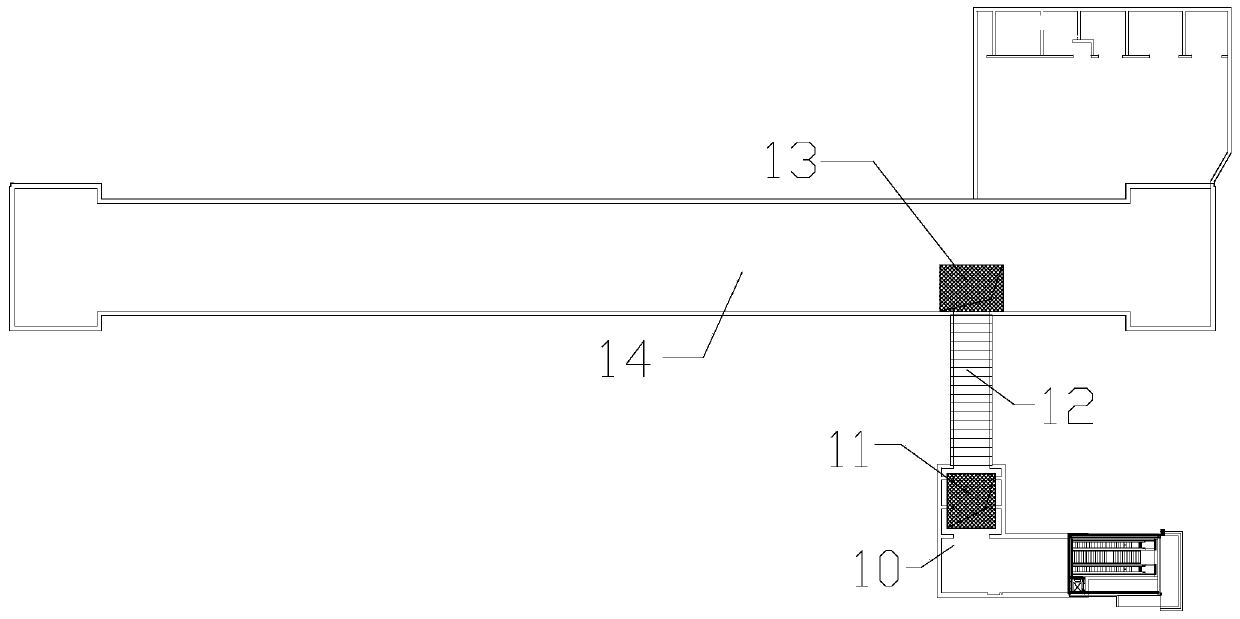

Rectangular pipe jacking construction method for outlet and inlet channel of subway station

ActiveCN111075474AReduce coefficient of frictionReduce frictional resistanceUnderground chambersTunnel liningLine tubingArchitectural engineering

The invention provides a rectangular pipe jacking construction method for an outlet and inlet channel of a subway station. The construction method specifically comprises the steps of constructing an initial well and a receiving well, calculating and determining jacking parameters, smearing wax on the outer wall of a pipe before jacking, connecting a head of a pipe jacking machine and three adjacent pipe sections into a whole during jacking, simultaneously injecting pressure injection thixotropic slurry into the back of the pipe sections in the jacking process, and arranging a stopping device to prevent the pipe jacking machine from retreating; erecting a receiving platform to receive the pipe jacking machine, after the jacking construction is finished, plugging pipe section gaps and the gaps between the pipe sections and two end openings, and finally adding cement slurry to replace the thixotropic slurry to consolidate a pipe jacking channel. It is ensured that the underground pipelinedoes not settle, crack, leak or the like, and compared with construction of a traditional open excavation method, the construction method has the advantages of small environmental impact, safe construction, simple operation, single procedure, low manufacturing cost, cost saving and good popularization significance.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP +1

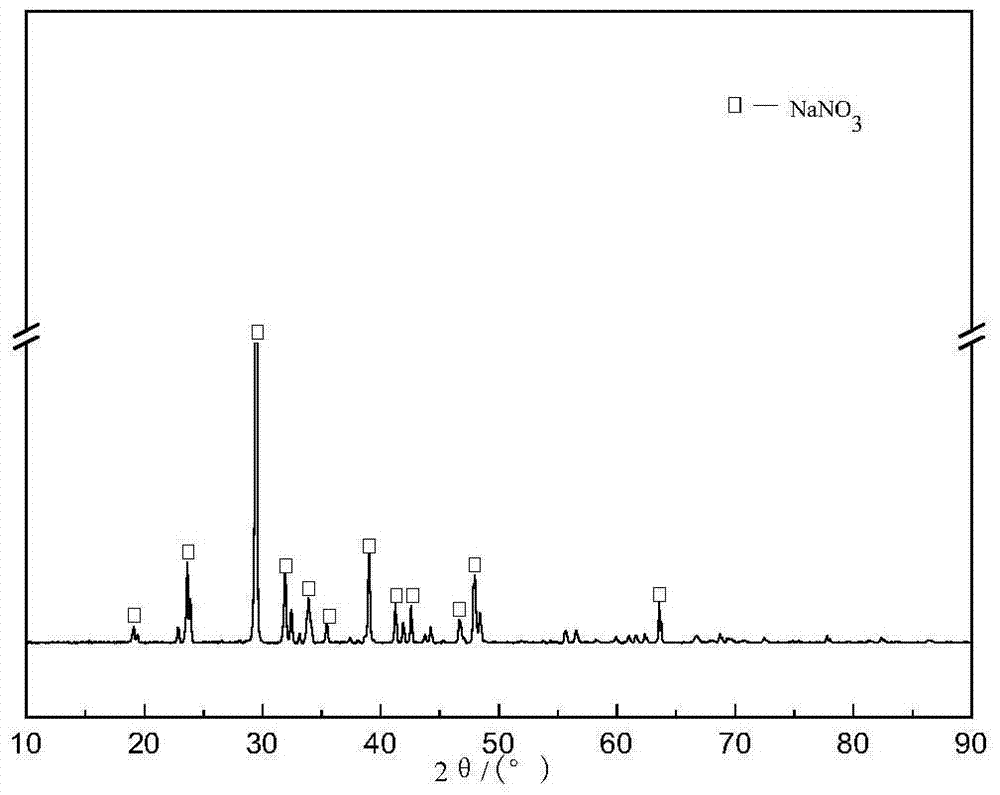

Harmless separating method of waste cathode carbon block in aluminum electrolysis

The invention discloses a harmless separating method of a waste cathode carbon block in aluminum electrolysis, and belongs to the technical field of inorganic chemicals. The method comprises the mainsteps of S1, crushing and screening the waste cathode carbon block in aluminum electrolysis to obtain carbon block particles; S2, preparing 1mol / L by concentration of acid liquid for later use; S3, leaching the carbon block particles obtained in step S1 in the acid liquid prepared in step S2 under heating and stirring conditions to obtain a leaching solution; S4, filtering the leaching solution obtained in step S3; separating filtrate and filter residues; and washing and drying the filter residues to obtain a carbon powder product; S5, adding the filtrate obtained in step S4 to a salt solution, and performing fluorine deposition to obtain a fluorine deposition solution; and S6, filtering the fluorine deposition solution obtained in step S5; separating the filtrate and a filter cake; and washing and drying the filter cake to obtain an alkaline metal fluoride product. With the adoption of the method, high-purity aluminum electrolyte applicable to industrial aluminum electrolysis production can be obtained; and villiaumite is recovered, so that the whole process is free from wastes.

Owner:NORTHEASTERN UNIV

Mutton fat matt white glaze for ceramic decoration and preparation method of white glaze

The invention discloses mutton fat matt white glaze for a ceramic decoration and a preparation method of the white glaze. The white glaze is prepared from, by mass percentage, 15-25% of feldspar powder, 10-17% of calcium carbonate, 5-7% of dolomite, 6-12% of talc, 3-8% of barium carbonate, 15-20% of zirconium silicate, 10-15% of zirconium white frit, 0-6% of zinc oxide, 5-7% of aluminum oxide and 0-12% of kaolin. The components are weighed according to the formula, fully mixed and added into a grinding tank, water with the weight 45-50% that of dry powder is added for grinding for 10-15 h, then glaze slurry obtained after ball milling is subjected to iron removal and screening, and the concentration is adjusted till the true specific gravity is 50-54 degrees. A ceramic product is coated with the white glaze in a spraying mode or a soaking mode or other decoration modes. After drying, the ceramic product enters a kiln to be oxidized and fired for 8-11 h at the temperature of 1200-1235 DEG C, and the ceramic product is taken out of the kiln after being naturally cooled. The prepared mutton fat matt white glaze has the advantages of being high in processing property, high in operability and not prone to cracking.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

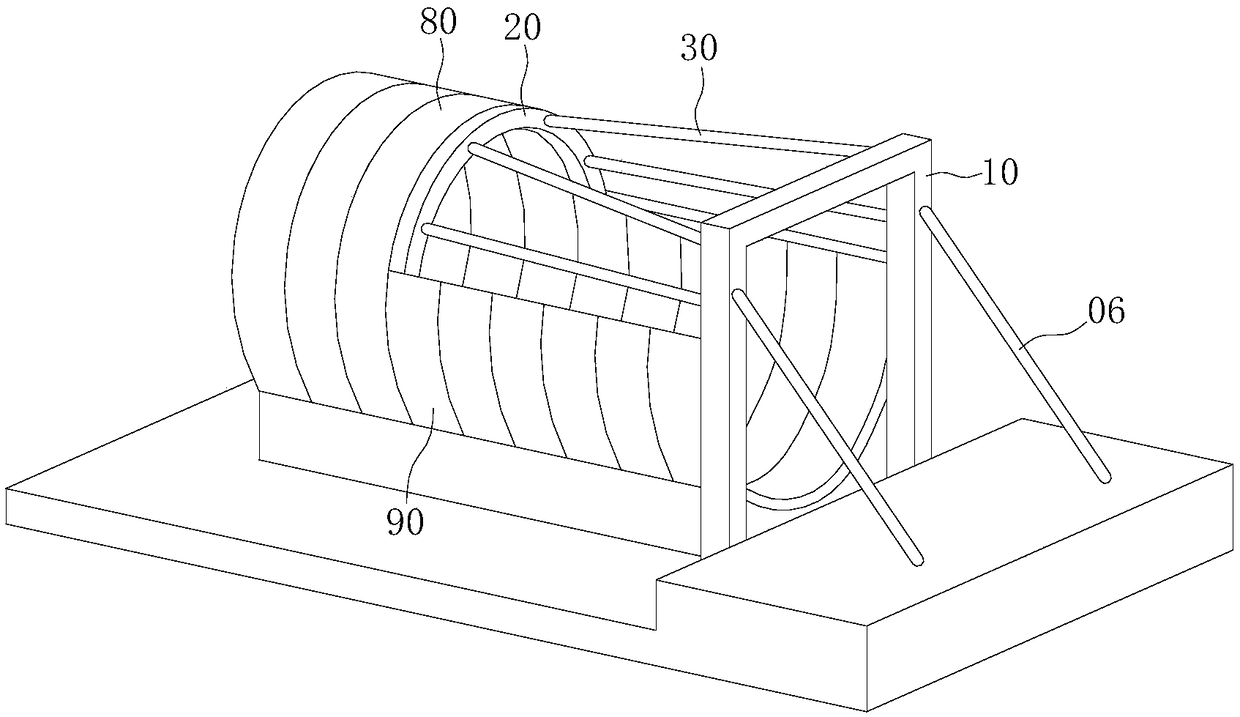

Method for preparing g-C3N4 hollow fiber film on large scale

The invention discloses a method for preparing a g-C3N4 hollow fiber film on a large scale. The method includes the following steps of putting melamine or urea or a mixture of melamine and urea in a muffle furnace, firing the material at a temperature of 450-600 DEG C for 1-4 hours to obtain yellow g-C3N4 blocks, evenly grinding the yellow g-C3N4 blocks to form g-C3N4 powder, putting the g-C3N4 powder in the muffle furnace, firing the g-C3N4 powder at a temperature of 400-700 DEG C for 1-4 hours to obtain g-C3N4 nanometer sheets, dispersing the g-C3N4 nanometer sheets and polymers in organic solvent to prepare a casting membrane solution, and spinning the casting membrane solution (as a shell solution) and water (as a core solution) in a coagulating bath at the same time through a spinning head of a spinning machine to obtain the g-C3N4 hollow fiber film, wherein the mass ratio of g-C3N4 nanometer sheets to polymer to organic solvent is 1:(0.2-1):(4-10) and the ratio of shell solution flow speed to core solution flow speed is (0.5-5):1.

Owner:DALIAN OCEAN UNIV

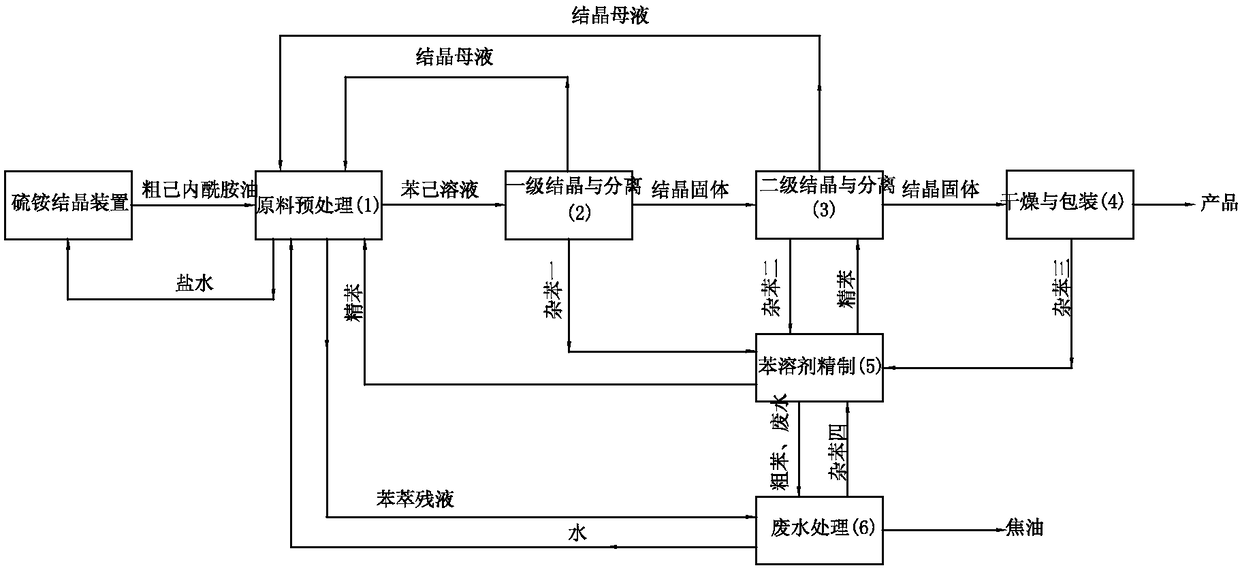

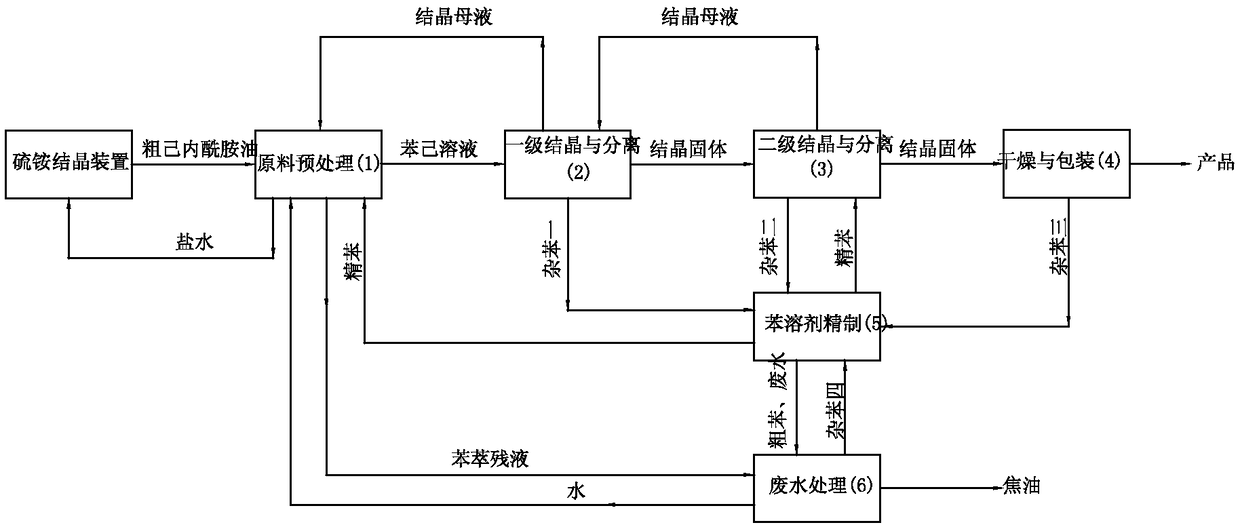

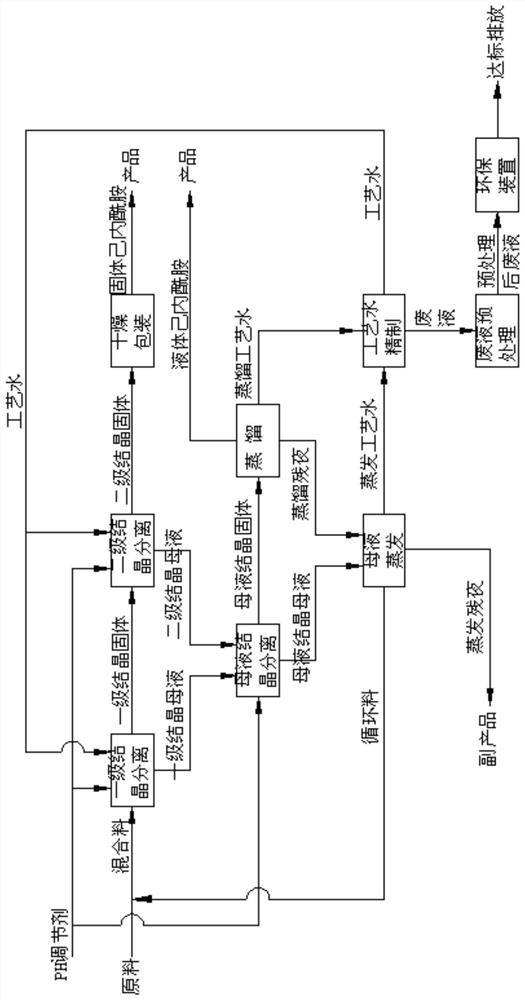

Method for refining caprolactam by organic solvent crystallization

InactiveCN108358823AQuality improvementLow energy consumption for crystallizationLactams separation/purificationWater/sewage treatment by heatingUltraviolet absorptionSolvent

The invention discloses a method for refining caprolactam by organic solvent crystallization. The method is concretely characterized in that solvent crystallization and recrystallization are used; a impurity-containing caprolactam water solution is subjected to benzene extraction to obtain a caprolactam solution; the caprolactam solution is subjected to evaporative crystallization and recrystallization to obtain high-quality caprolactam; benzene is refined to be cyclically used. The solvent crystallization and recrystallization are used for realizing impurity-containing caprolactam refining and purification; the process energy consumption is low; the product yield is high; the technological process is short; the equipment investment is low; the product quality is good; various items of indexes such as the chromaticity, the acidity and alkalinity, the volatile alkali content, the ultraviolet absorption value and potassium permanganate oxidation value of the finished product can stably reach national standard premium grade requirements; meanwhile, the discharge of three wastes (waste water, waste gas and waste solid) is little; the environment pollution is little.

Owner:陕西宏元化工技术有限公司

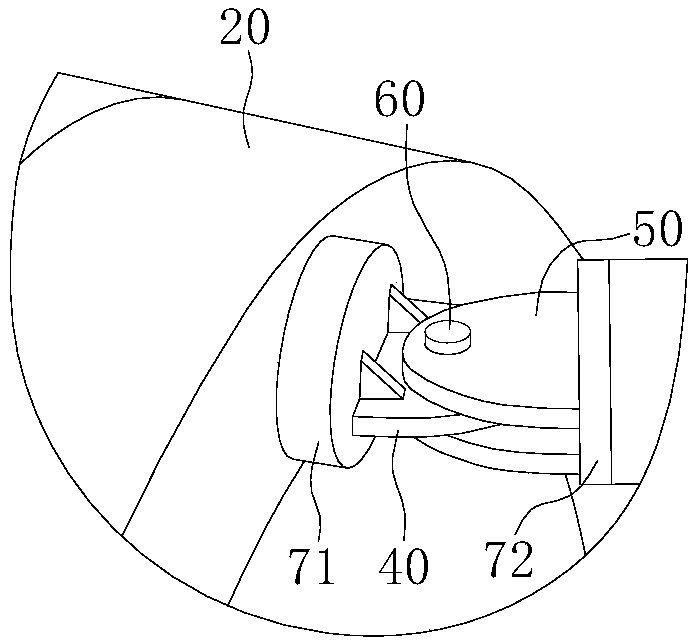

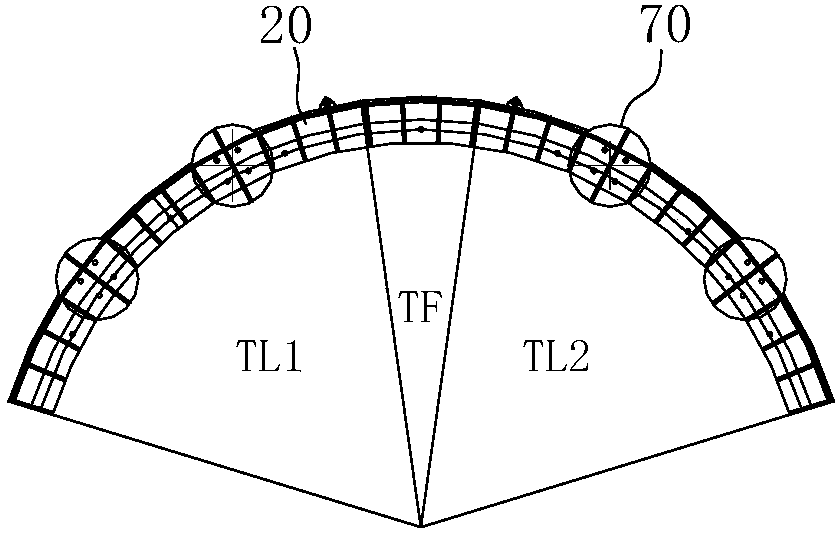

Upper reaction support system and construction method for shield-semi-ring origination

ActiveCN108104836ALevelingPlay ellipticityUnderground chambersNuclear energy generationSupporting systemArchitectural engineering

The invention discloses an upper reaction support system for shield-semi-ring origination, and provides a construction method for shield-semi-ring origination based on the support system. The supportsystem includes a reaction force frame, and further includes a support plate and a plurality of support rods; the support plate is fixed on the rear side of a nearest integral ring segment, and the support plate corresponds to the shape, size, and position of the part of the nearest integral ring segment which exceeds semi-ring segments; and one ends of the support rods are separately fixedly connected with the reaction force frame, and the other ends of the support rods are separately connected with the support plate in a hinged mode. According to the upper reaction support system and a construction method for the shield-semi-ring origination, the support plate serves as a connecting hinge from semi rings to integral rings to play a fixed and stable role, and since the other ends of the support rods are hinged to the support plate, so that the force bearing point and direction of the support position can be adjusted; and thus the smoothness and ellipticity of assembly of the semi-ringsegments and integral ring segments can be ensured, thereby ensuring the origination attitude of a shield tunneling machine.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

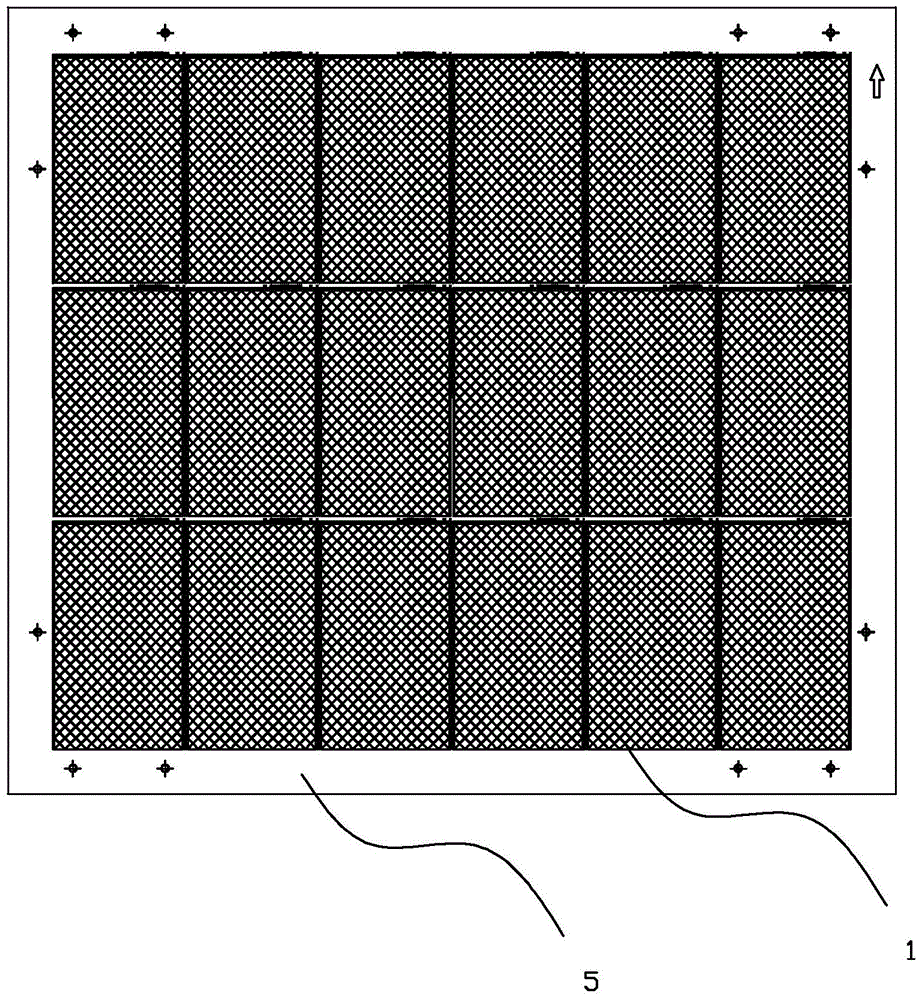

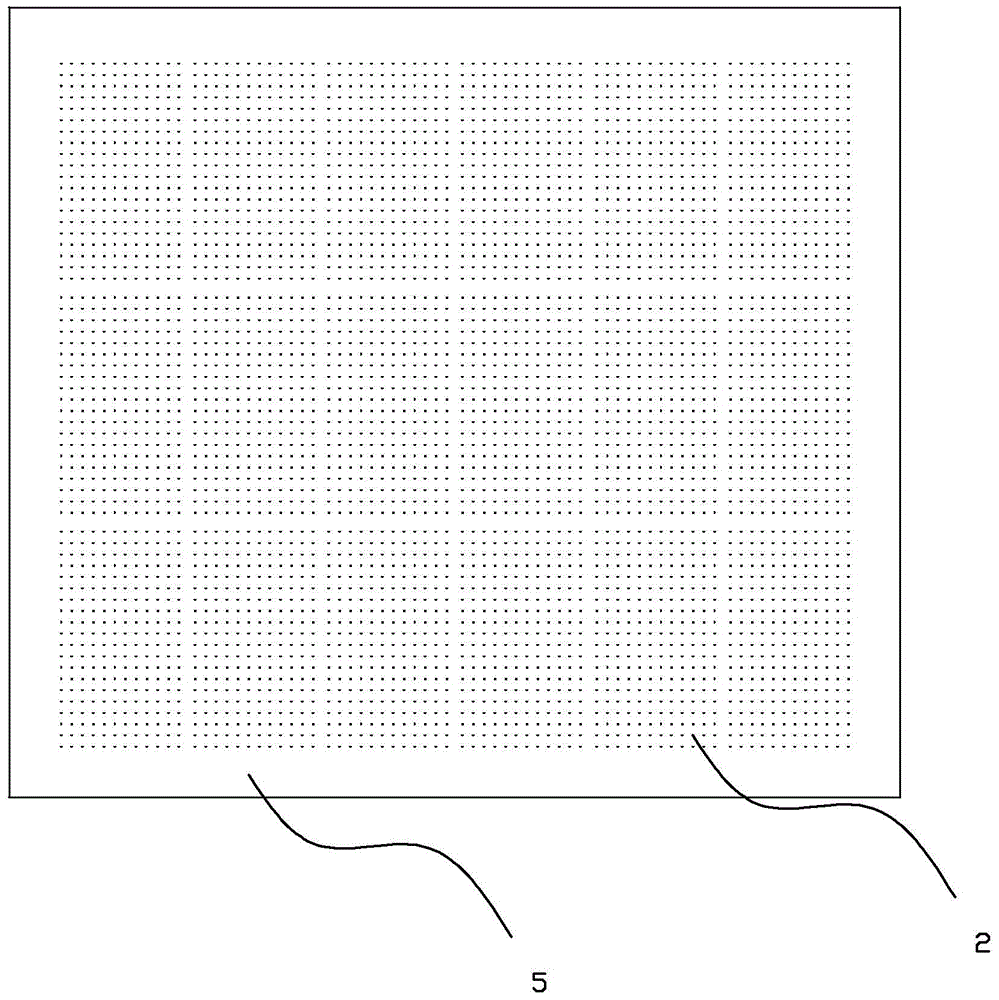

Manufacturing process of multi-point touch single-layer film touch sensor

InactiveCN103914199AReduce configurationSave configuration spaceInput/output processes for data processingChemical solutionAdhesive

The invention relates to a manufacturing process of a multi-point touch single-layer film touch sensor. The process is based on a three-dimensional (3D) printing process to perform layering printing on functional images of the sensor by starting from the bottom layer and overlaying the images layer by layer; after the functional images are formed, the functional images are glued to optical adhesive to be subjected to de-foaming, cutting and forming, and the manufacturing process of the multi-point touch single-layer film touch sensor can be achieved. The manufacturing process of the multi-point touch single-layer film touch sensor has the advantages that the process is single, configuration space of a factory is small, a single 3D printer device is merely required, personnel allocation is small, and producing costs are sharply reduced; the utilization ratio of raw materials is high, and consumables are used for solid printing of functional zone patterns by nearly 100%; proofing can be rapidly achieved, and the production cycle is shortened; the production line is quite short, deficient manufacturing procedure factors are few, and the product yield of the manufacturing process is higher than that of traditional processes; chemical solution treatment is absent, and producing costs are further lowered compared with those of the traditional processes; different dots per inch (dpi), each layer film thickness and the number of layers are set on a 3D printer to manufacture electrode patterns with different impedances.

Owner:FUJIAN BAOFA PHOTOELECTRIC TECH

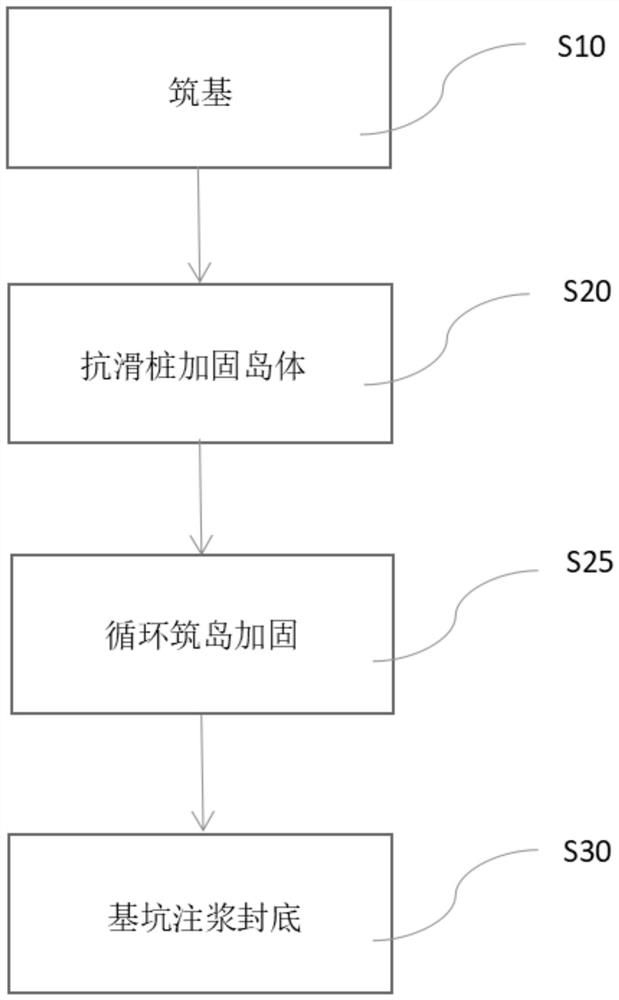

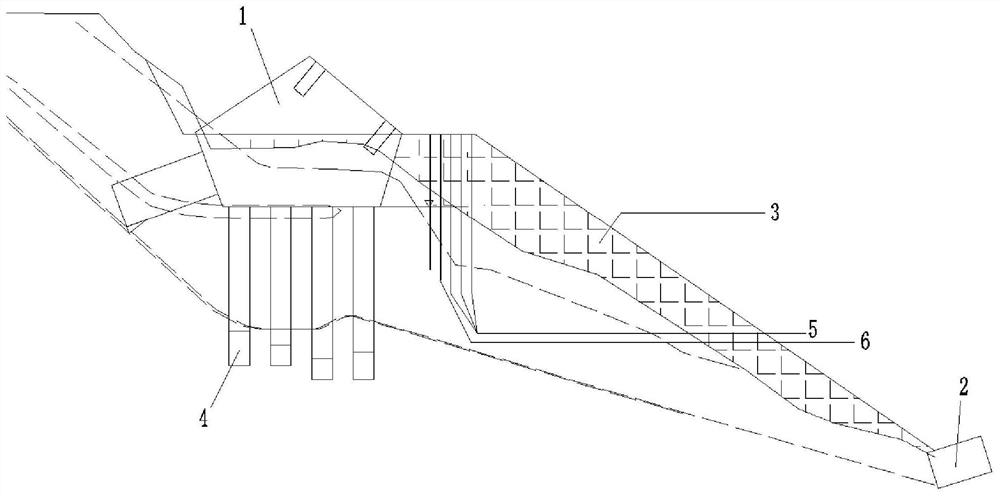

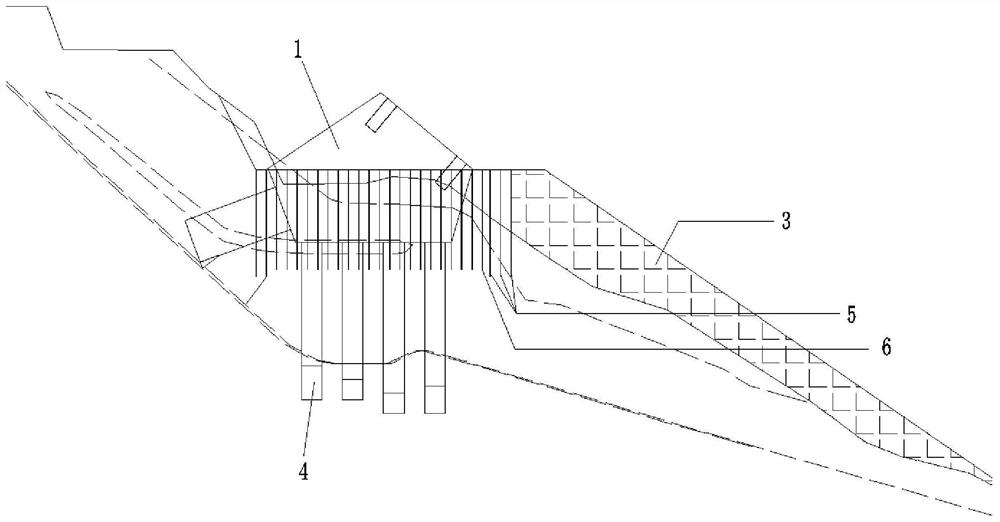

Stone filling and island building construction bearing platform method for underwater stone abrupt slope area

InactiveCN112227401AEnsure excavation safetyImprove lateral stabilityEmbankmentsLand reclamationSlurryRebar

The invention discloses a stone filling and island building construction bearing platform method for an underwater stone abrupt slope area. Grouting steel sleeves, thick steel bars and cement-water glass double-liquid slurry are used for forming composite small anti-slide piles to resist an island building body from sliding down into a river, so that the island building area and the backfill engineering quantity are reduced, the construction period and the construction cost are saved, and the construction safety can further be ensured. The grouting steel sleeves are not taken out, so that thelateral stability of a bearing platform foundation pit in the later period is improved, and foundation pit excavation safety is guaranteed. Curtain grouting of the periphery of a foundation pit and bottom sealing grouting of the bottom of the foundation pit are carried out by adopting the cement-water glass double-liquid slurry, bearing platform foundation pit water stopping is carried out, the water stopping effect is good, secondary water stopping is not needed in subsequent bearing platform foundation pit excavation, and maximization of economy, safety and practicability is achieved. Compared with the prior art, large equipment is not needed, a large number of steel structures are not needed, the structure is safe, the procedure is single, and economical efficiency is good. The problemthat the bearing platform in the underwater stone abrupt slope area is difficult to construct is solved.

Owner:CENT SOUTH UNIV

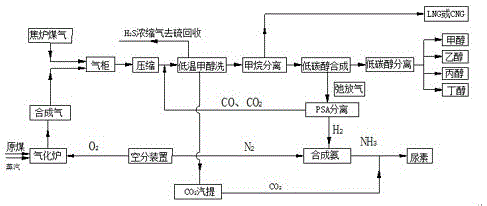

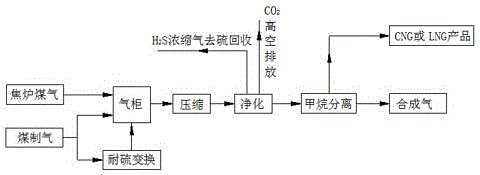

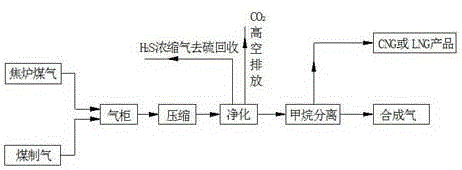

Method for production of low carbon alcohol and combined production of natural gas and urea from synthetic gas and coke oven gas

ActiveCN105061264AAdjustable structureImprove efficiencyUrea derivatives preparationOrganic compound preparationAlcohol productsMethane

A method for production of low carbon alcohol and combined production of natural gas and urea from synthetic gas and coke oven gas comprises the following steps: mixing crude synthetic gas with coke oven gas to form raw gas with a hydrogen / carbon ratio meeting low carbon alcohol synthesis; carrying out low temperature methanol washing on the raw gas, carrying out desulfurizing recovery on removed hydrogen sulfide, and carrying out CO2 stripping on removed carbon dioxide to realize purification; carrying out methane separation on the low temperature methanol washed raw gas, preparing LNG or CNG by using the removed methane, carrying out a low carbon alcohol synthesis reaction on methane separated purified gas, carrying out PSA separation on the obtained gas as a purge gas, returning separated gases mainly comprising CO, CO2 and CH4 to the low temperature methanol washing, and carrying out an ammonia synthesis reaction on separated H2 and N2 obtained after air separation to prepare synthetic ammonia; carrying out a urea synthesis reaction on purified CO2 and the synthetic ammonia to prepare a urea product; and carrying out low carbon alcohol separation on obtain liquid phase products to obtain a low carbon alcohol product. The method improves the utilization rate of the raw gas.

Owner:SEDIN ENG

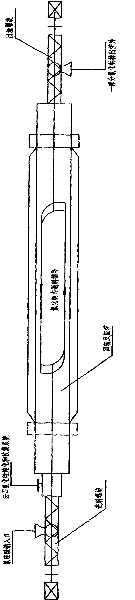

Method for preparing silicon tetrafluoride through pyrolysis of sodium fluosilicate in rotary reaction furnace

The invention provides a process for preparing silicon tetrafluoride through pyrolysis of sodium fluosilicate in a rotary reaction furnace, which comprises the steps of: performing drying and heat treatment on the sodium fluosilicate at a temperature of between 200 and 300 DEG C in a calciner to remove the moisture in the sodium fluosilicate, and maintaining a negative pressure in the calciner, wherein the negative pressure value is controlled to between 10 and 30mmH2O; and sending the dried sodium fluosilicate into the rotary reaction furnace for the pyrolysis at a temperature of between 500and 900 DEG C (material temperature) for 1 to 2 hours, and obtaining the silicon tetrafluoride and sodium fluoride after the pyrolysis. The generated silicon tetrafluoride gas is dedusted, cooled, dried, compressed and collected to form high-purity silicon tetrafluoride gas. The process has the advantages of single reactant and no discharge of waste gas, waste water and waste residue, and belongsto an environmentally-friendly comprehensive utilization project.

Owner:西安三瑞实业有限公司 +1

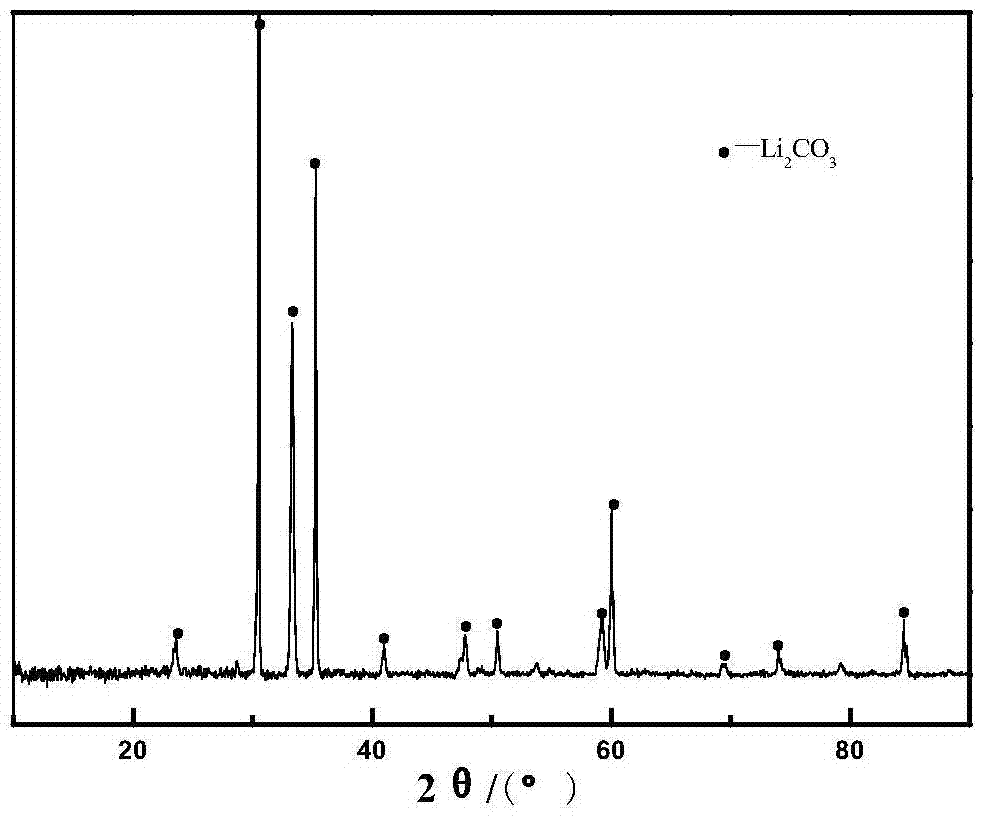

A method for extracting lithium salt in aluminum electrolyte by fluorination roasting and acid leaching

ActiveCN105543504BReduce energy consumptionEfficient extractionProcess efficiency improvementChemical industryAluminium electrolysis

Owner:NORTHEASTERN UNIV LIAONING

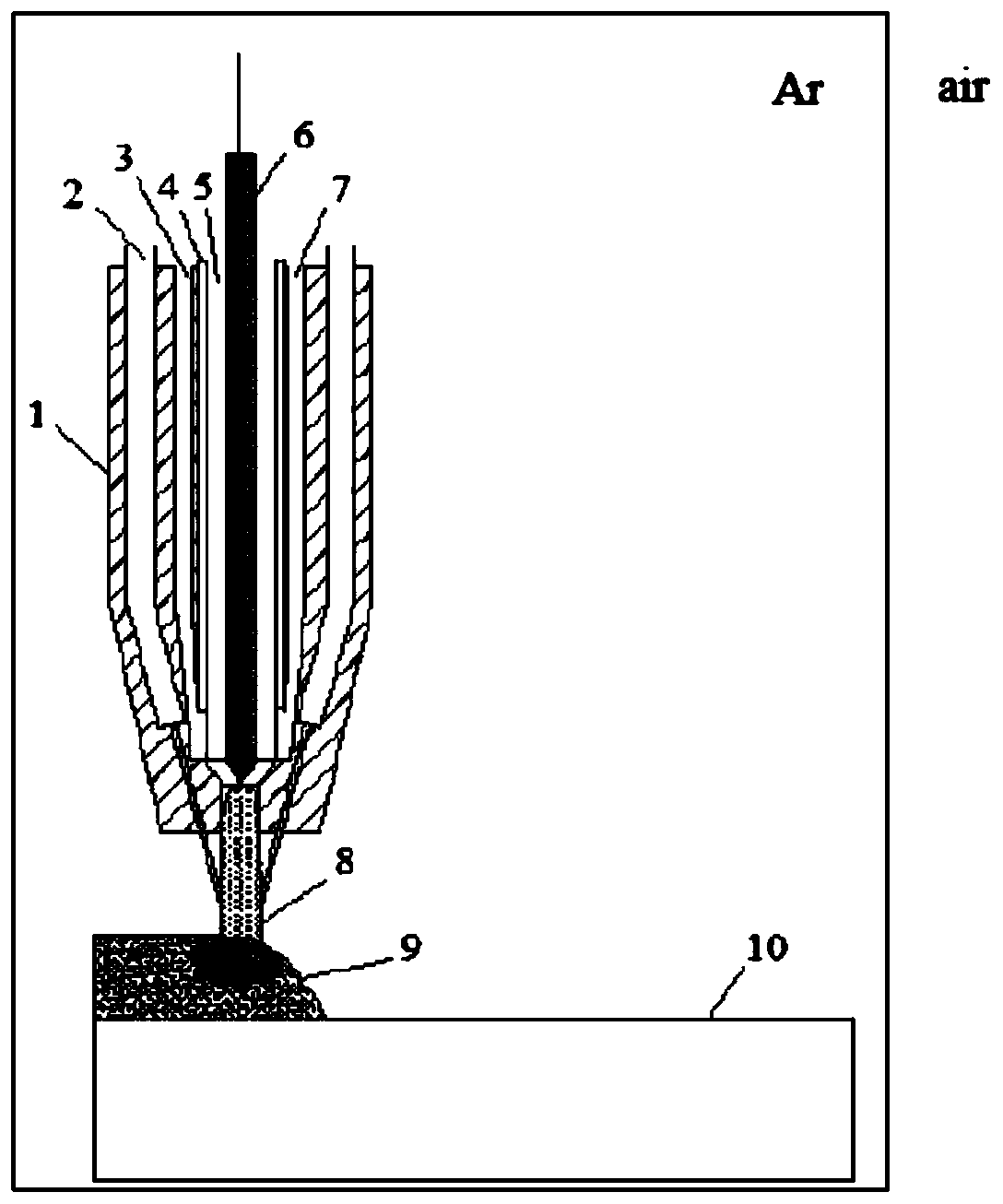

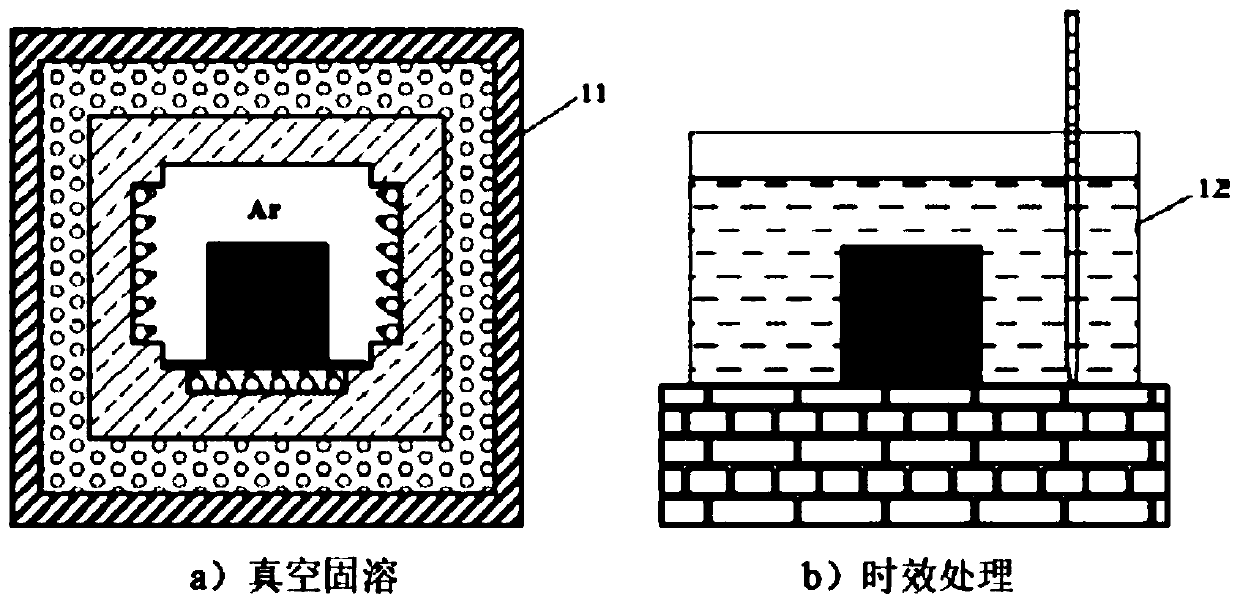

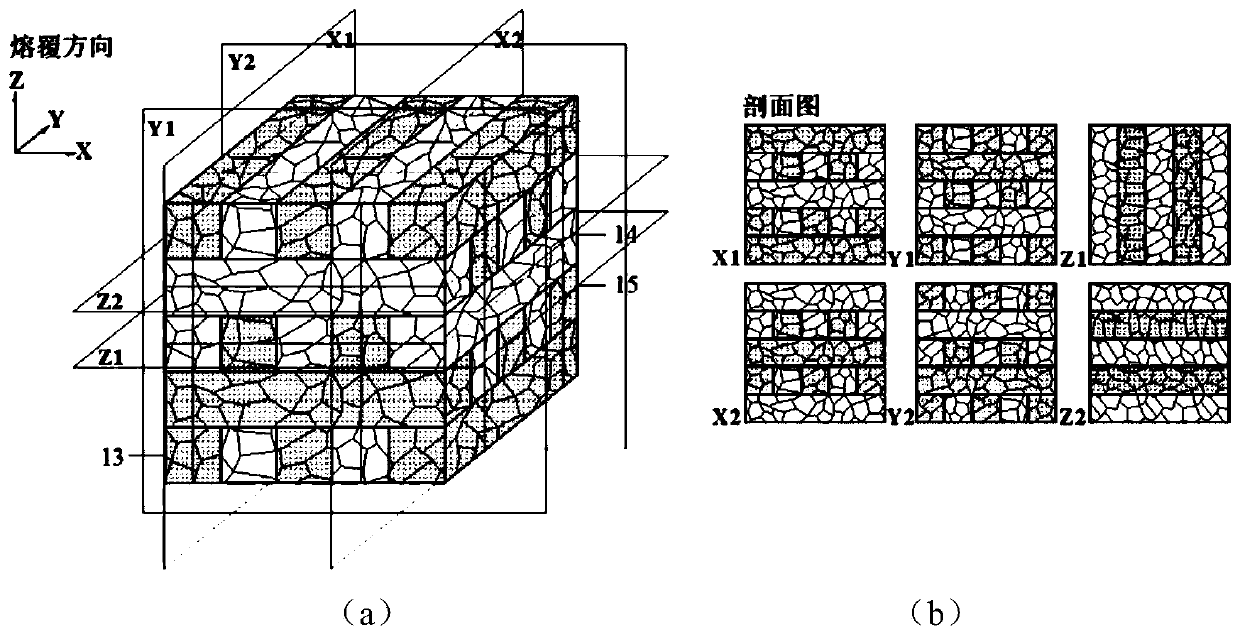

Method for preparing heterogeneous material through plasma cladding

ActiveCN111347043AReduce the difficulty of operationSingle processAdditive manufacturing apparatusIncreasing energy efficiencyLap jointSolution treatment

The invention belongs to the field of preparation of heterogeneous materials, and particularly relates to a method for preparing a heterogeneous material through plasma cladding. The method includes the four procedures of pre-treatment, bottom layer cladding, multi-layer cladding and solution treatment and aging precipitation, and comprises the specific steps that plasma cladding is utilized, a high-strength material B is cladded on a high-toughness material A matrix, then the high-toughness material A is cladded on a high-strength material B matrix, the above operation is repeated according to a specific lap joint and stacking mode, finally the heterogeneous material controllable and devisable in a three-dimensional direction is obtained through solid treatment and aging precipitation, and finally high strength and high toughness of the material are achieved. According to the method, the multi-layer complex heterogeneous composite material is prepared through the plasma cladding process and solid treatment and aging precipitation, so that impurity doping and interfacial oxidation are effectively avoided, industrial production is easy, the applicable raw material range is wide, cladding patterns and shapes are diversified, and a heterogeneous structure is controllable and devisable in the three-dimensional direction.

Owner:NANJING UNIV OF SCI & TECH

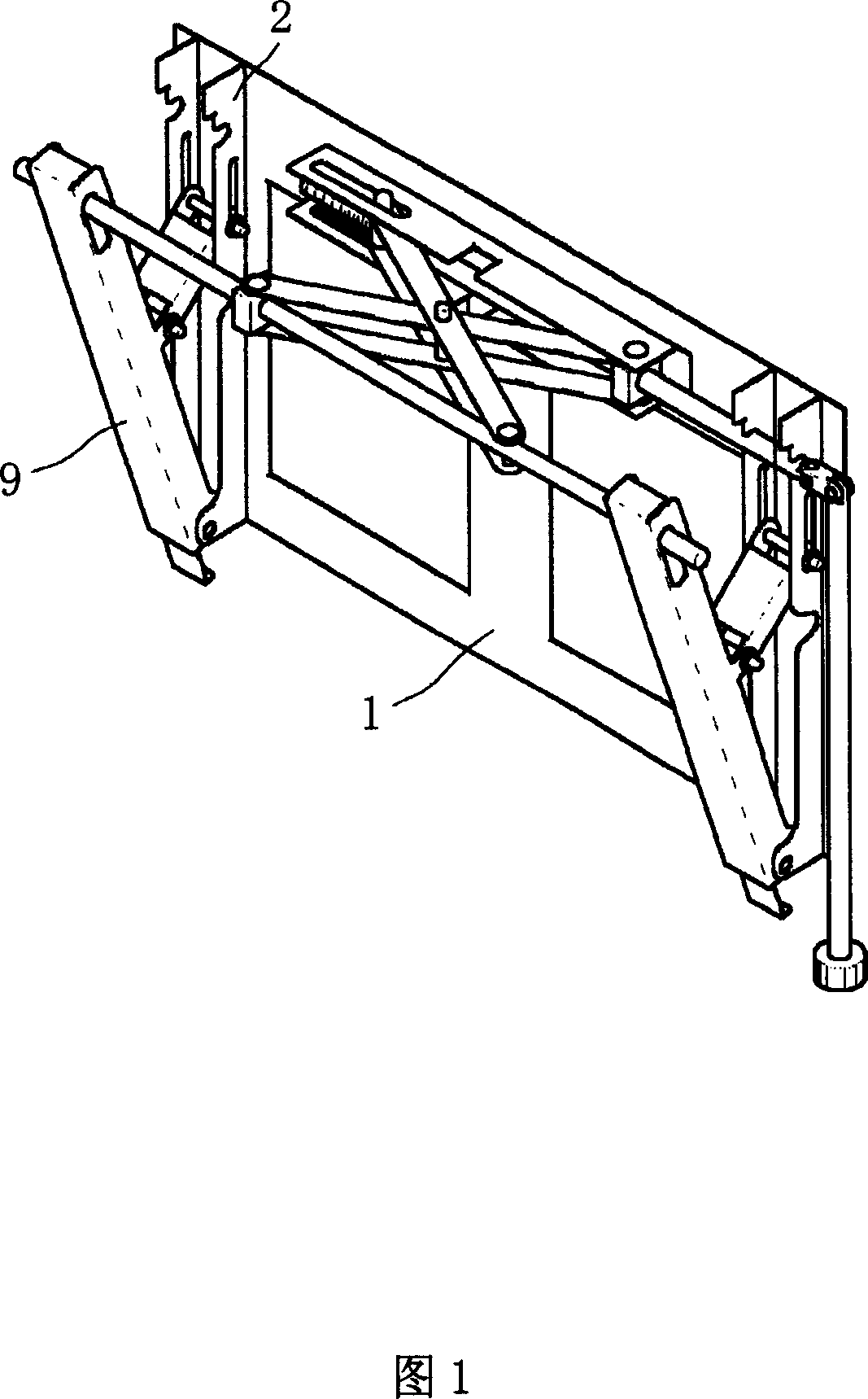

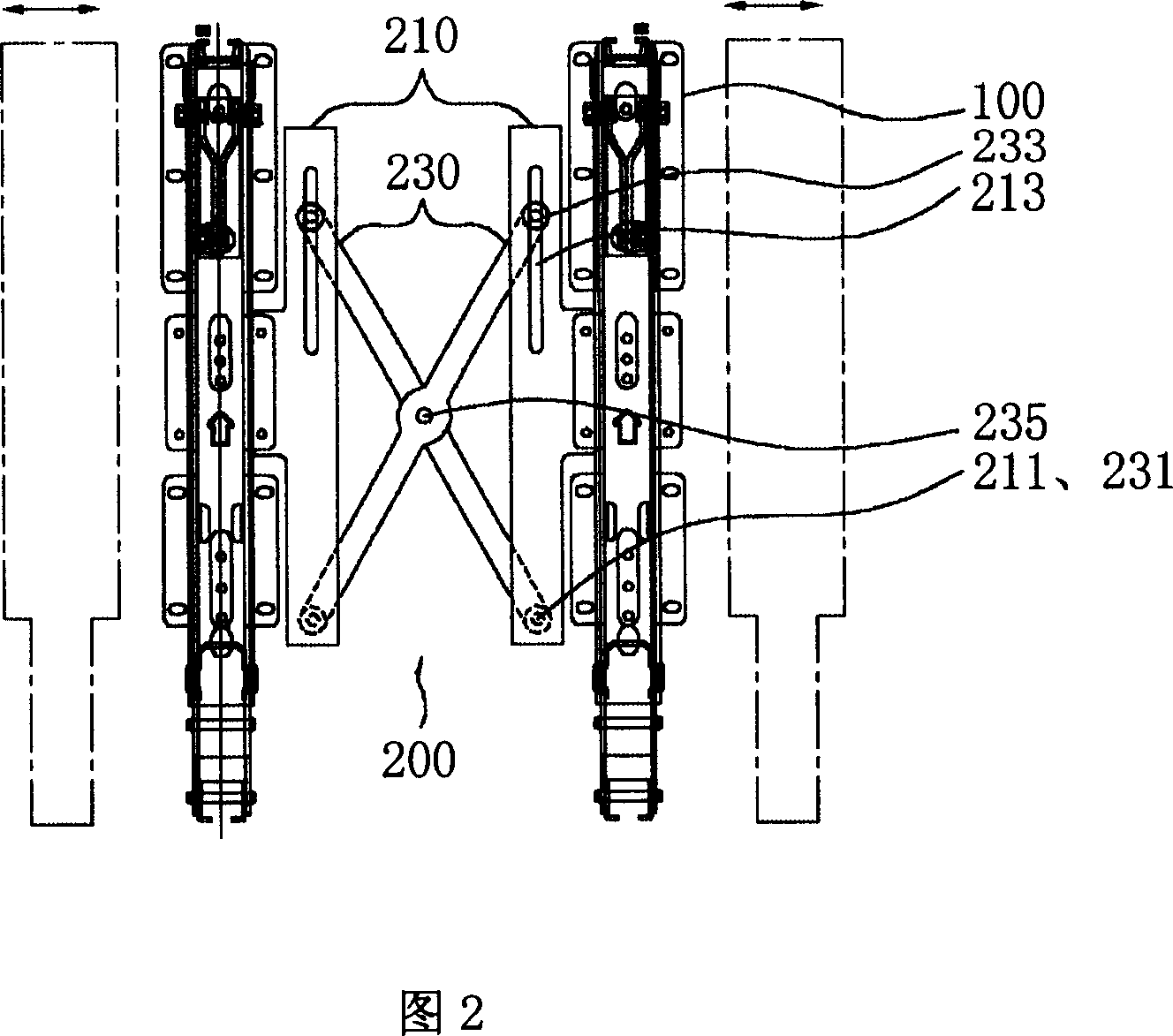

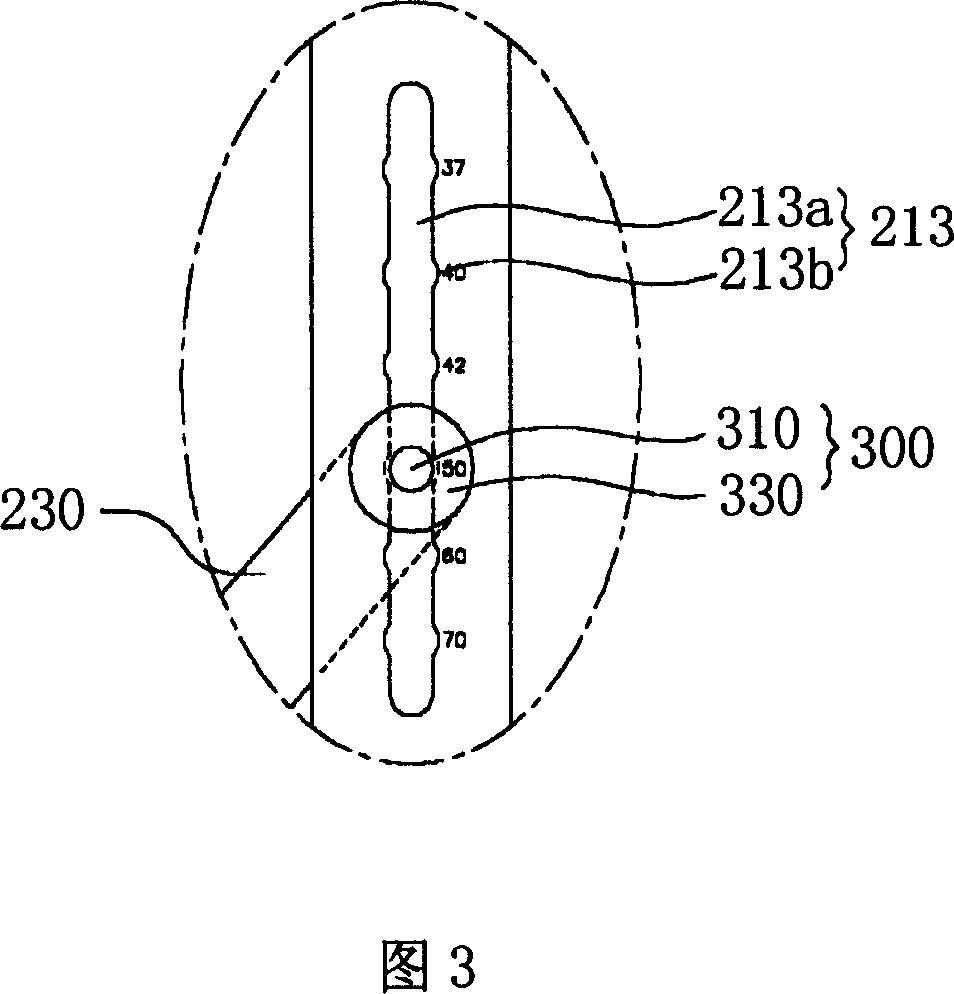

Wall hanging device for pictorial display apparatus

InactiveCN1992090ASingle processReduce logistics costsMachine supportsInstrument housingDouble wallEngineering

The invention relates to a wall device of image display device, specially one wall device for multi-size image display device. It includes a double-wall bracket and a position changeable component equipped with an X-type plate which can adjust the distance of said double-wall bracket shift right and left; because the invention uses wall device suits for position changeable component, the fixed position of wall bracket can be adjusted based on the size of image display device, so it possesses effect of suiting for multi-size image display. The product line can be unionized, and the technological process is single, the logistics cost is decreased.

Owner:LG ELECTRONICS(NANJING) PLASMA CO LTD

Production process for drawing and twisting aluminum wire

InactiveCN106448944AAvoid darkeningGuaranteed gluing effectCable/conductor manufactureSocial benefitsHeating furnace

The invention discloses a production process for drawing and twisting an aluminum wire. The production process comprises the following steps: S1, selecting materials: selecting an aluminum rod and a mold, which meet drawing and twisting requirements; S2, heating: putting the selected aluminum rod and mold into a heating furnace; S3, drawing: matching with the mold and stretching to form the aluminum wire; S4, cooling: rapidly putting the aluminum wire formed by stretching into a cold water groove; S5, drying by blowing: putting the cooled aluminum wire onto a blow drying machine and carrying out blow drying treatment; S6, coating oil: coating one layer of anti-oxidization oil on the surface of the aluminum wire; S7, turning: putting the aluminum wire on a special twisting disc and turning the aluminum wire; S8, adjusting: uniformly adjusting payoff tension as much as possible; and S9, twisting: carrying out inching operation to finish aluminum wire twisting. By adopting the production process for drawing and twisting the aluminum wire, problems that the aluminum wire becomes black due to an annealing process and the appearance is damaged are effectively avoided; and a lead wire gluing effect is guaranteed, and economic and social benefits are improved.

Owner:JIANGSU PROVINCE WEINENGDA WIRE & CABLE

Method used for producing synthesis gas from coke oven gas and coal gas

ActiveCN105000533ASingle processEasy to operate and manageHydrogen separationGaseous fuelsCompressed natural gasChemistry

The invention discloses a method used for producing synthesis gas from coke oven gas and coal gas. According to the method, coke oven gas and a part of coal gas are delivered into a gasometer for mixing, and the other part of coal gas is subjected to sulfur-resistant water gas shift; obtained shifted gas and gas obtained via mixing in the gasometer are mixed, an obtained mixed gas is subjected to compression, purifying, and removing of impurities such as hydrogen sulfide; the obtained hydrogen sulfide is subjected to desulphurizing recovery, and removed CO2 gas is discharged; a crude raw material gas obtained via hydrogen sulfide removing is subjected to methane separation; an obtained methane-free gas is prepared into purified synthesis gas with qualified hydrogen-carbon ratio, and methane obtained via separation is prepared into liquefied natural gas products or compressed natural gas products. Comprehensive utilization of coke oven gas and coal gas is realized.

Owner:SEDIN ENG

Sea reef glaze for pottery ornaments and preparation method of sea reef glaze

The invention discloses sea reef glaze for pottery ornaments and a preparation method of the sea reef glaze. A technical formula of the sea reef glaze comprises the following components in percentage by mass: 3%-8% of nepheline orthoclase, 35%-55% of high alumina powder, 10%-30% of wollastonite, 3%-8% of dolomite, 10%-20% of calcium carbonate, 3%-8% of talc, 3%-8% of glaze clay and 0.5%-1.5% of CuCO3. The components are weighed according to the formula, fully mixed, and then added to a grinding tank; moisture accounting for 45%-50% the weight of dry powder is added for grinding for 10-15 hours, the concentration of the ground glaze slurry is adjusted until the true specific gravity is 45-50 when the residue rate is 0.1%-0.3% after the powder is screened with a 325-mesh screen, and the glaze slurry is applied to a pottery product through spraying or immersion, is aired and then fired in a kiln at the temperature of 1200-1235 DEG C for 8-11 hours; finally, the glaze is cooled naturally and taken out of the kiln. The prepared sea reef glaze has simple color and luster, is diversified, appears to be matte and rough and also has natural texture like clay glaze.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

Method for producing synthetic gas

ActiveCN105132054AImprove thermal stabilityGood chemical stabilityGaseous fuelsSyngasCompressed natural gas

A method for producing synthetic gas comprises: coke gas and coal based syngas are fed in the cabinet and fully mixed to make crude material gas where the mol rate of hydrogen and carbon is 1.0-5.0, which meets the requirement of downstream synthesis. The crude material gas is compressed, purified, then removed of H<2>S, CO<2>; the removed hydrogen sulfide is recovered after removing sulfur, and the removed carbon dioxide is evacuated. Purified crude material gas is separated from methane which is prepared for liquefied natural gas products or compressed natural gas, then the crude synthetic gas becomes purified synthetic gas meeting the hydrogen / carbon ratio of the requirement of downstream synthesis. The invention has advantages of comprehensive utilization of coke gas and coal based syngas.

Owner:SEDIN ENG

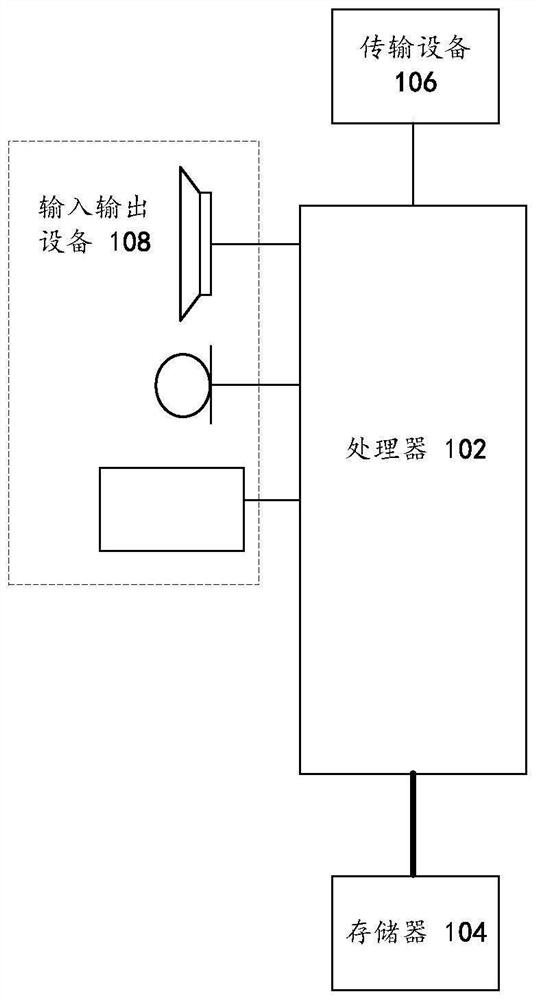

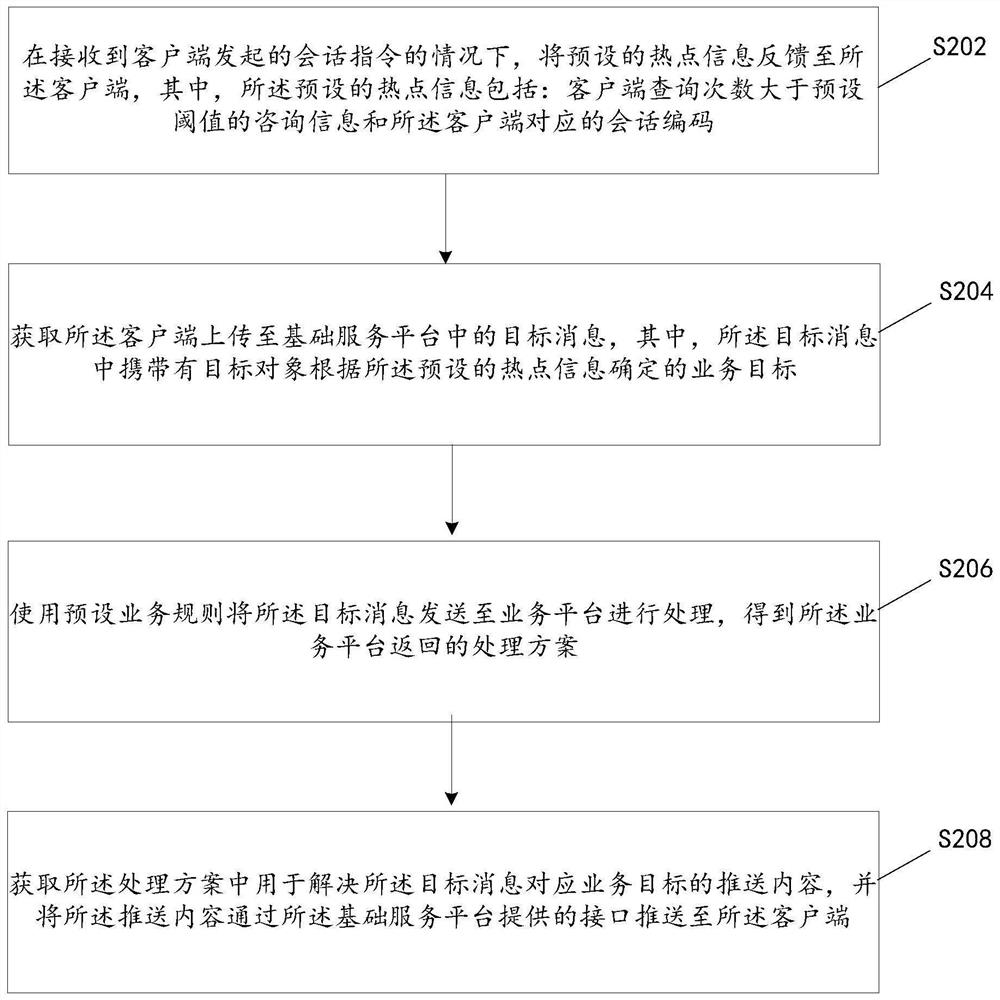

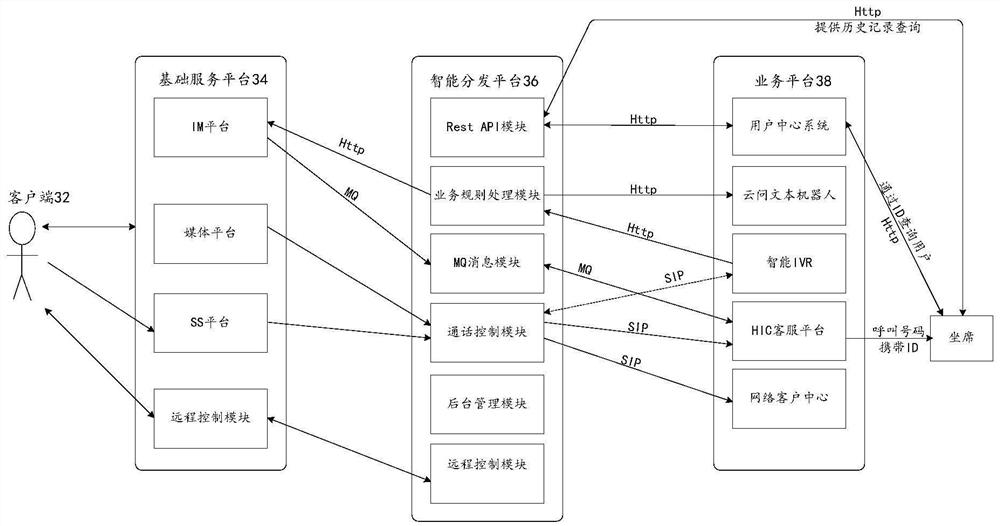

Message processing method and system, storage medium and electronic device

The invention provides a message processing method and system, a storage medium and an electronic device, and the method comprises the steps: feeding back preset hotspot information to a client under the condition that a session instruction initiated by the client is received, the preset hotspot information comprises consultation information of which the query times of the client are greater than a preset threshold value and a session code corresponding to the client; a target message uploaded to the basic service platform by the client is acquired, and the target message carries a business target determined by a target object according to preset hotspot information; sending the target message to a service platform for processing by using a preset service rule to obtain a processing scheme returned by the service platform; and obtaining push content used for solving the business target corresponding to the target message in the processing scheme, and pushing the push content to the client through an interface provided by the basic service platform. The problems that in the prior art, the message processing mode of the customer service request type is single, and message management cannot be carried out in a unified mode are solved.

Owner:QINGDAO HAIER TECH +1

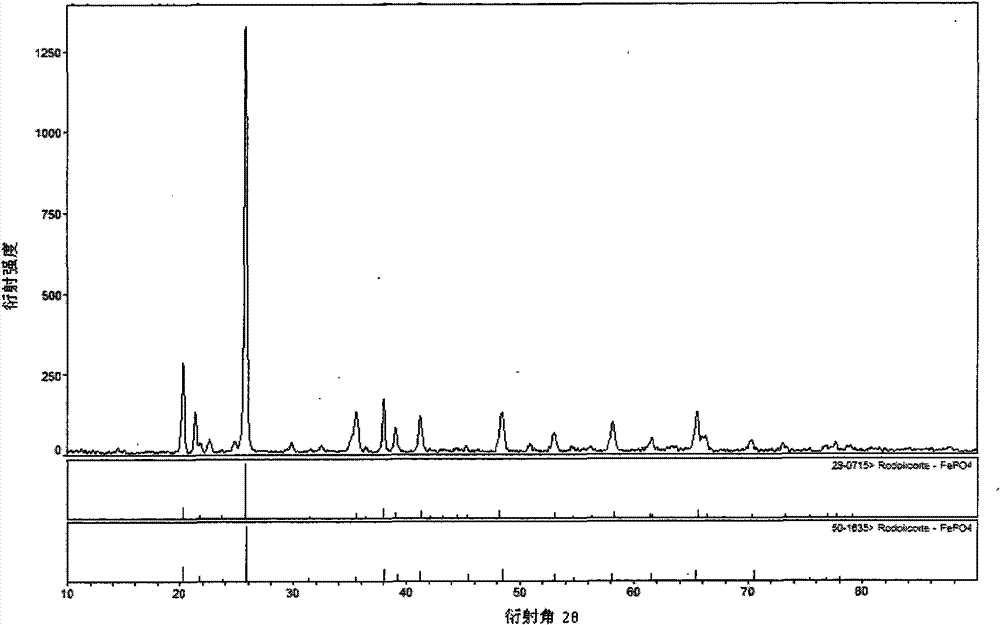

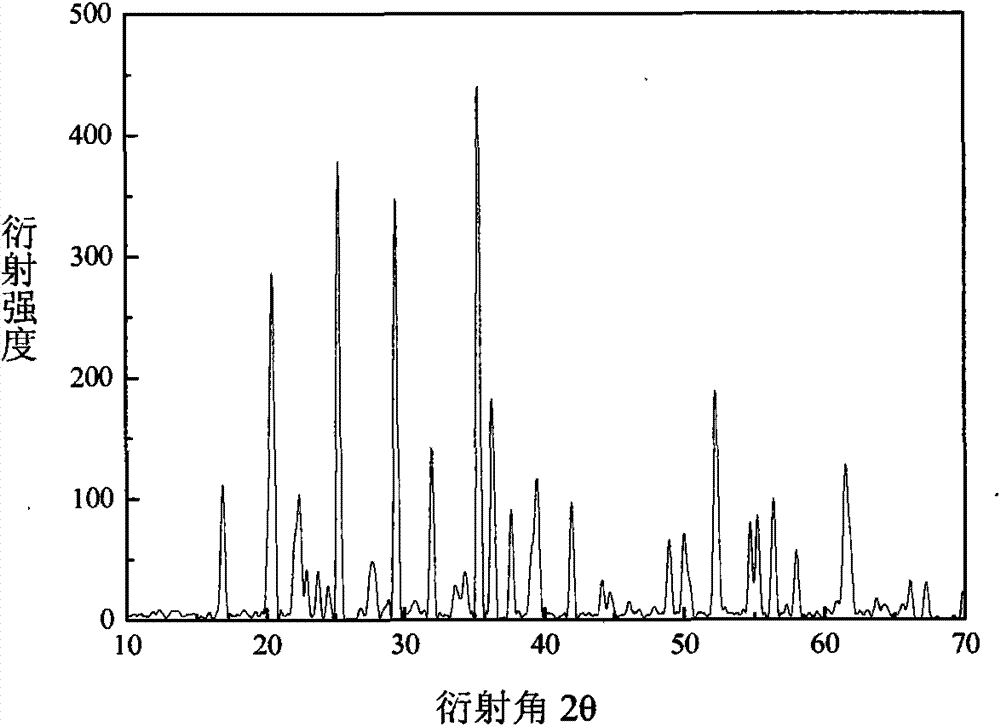

Method for preparing FexPO4 by electrolyzing ferrophosphorus

InactiveCN102051629BOvercome the problem of difficult ratioEliminate consumptionElectrodesChemical industryElectrolysis

Owner:SICHUAN UNIV

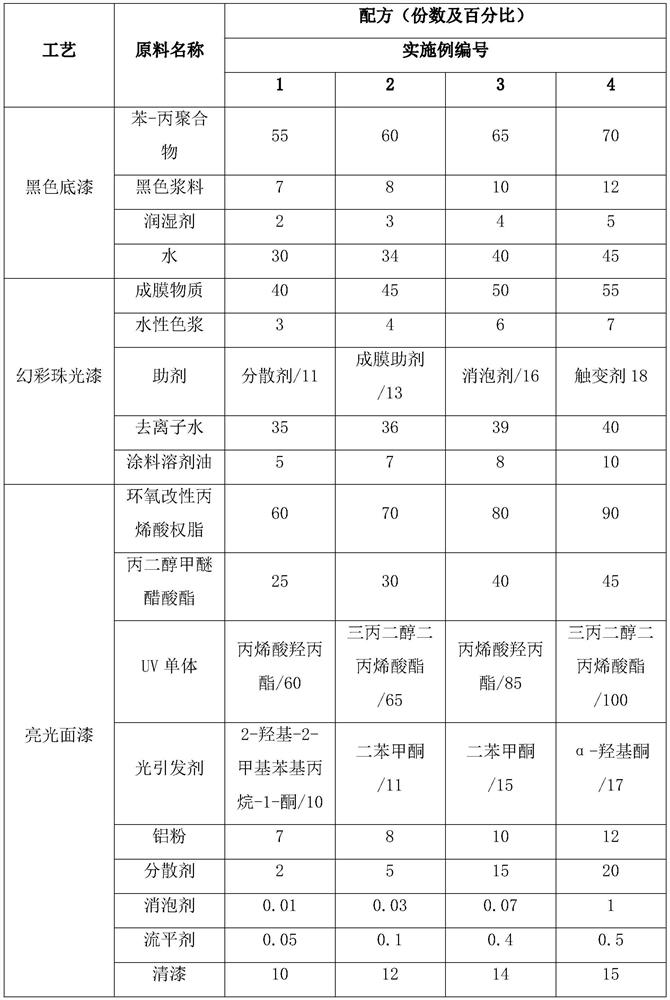

Colorful paint and spraying method thereof

InactiveCN111704832ASimple processing technologySimple processingFireproof paintsPretreated surfacesPhotoinitiatorAcrylic acid

The invention discloses a colorful paint and a spraying method thereof. The colorful paint comprises a black primer, a colorful pearlescent paint and a glossy finish paint. The black primer is prepared by mixing following raw materials in parts by weight: 55-70 parts of a styrene-acrylic polymer, 7-12 parts of black slurry, 2-5 parts of a wetting agent and 30-45 parts of water; and the colorful pearlescent paint comprises the following components in percentage by mass: 40-55% of a film-forming substance, 3-7% of water-based color paste, 11-18% of an auxiliary agent, 35-40% of deionized water and 5-10% of coating solvent oil. The glossy finish paint is prepared by mixing the following raw materials in parts by weight: 60 to 90 parts of epoxy modified acrylic resin, 25 to 45 parts of propylene glycol methyl ether acetate, 60 to 100 parts of UV monomer, 10 to 17 parts of a photoinitiator, 7 to 12 parts of aluminum powder, 2 to 20 parts of a dispersing agent, 0.01 to 1 part of an antifoaming agent, 0.05 to 0.5 part of a leveling agent and 10 to 15 parts of varnish. The black primer of the colorful paint is good in adhesion performance, the colorful pearlescent paint is long in storageperiod, resistant to abrasion and scratching, and the glossy finish paint is high in adhesion force, high in heat resistance and resistant to yellowing. The invention also relates to a spraying methodof the color paint, and the spraying method is easy to operate.

Owner:HUIZHOU SHENGYUANHENG CRAFTS

A method for harmless and resourceful treatment of waste aluminum electrolyte

ActiveCN108677020BEfficient decompositionSolve environmental problemsSulfate/bisulfate preparationAlkali metal nitrate preparationAluminum fluorideElectrolysis

Owner:NORTHEASTERN UNIV LIAONING

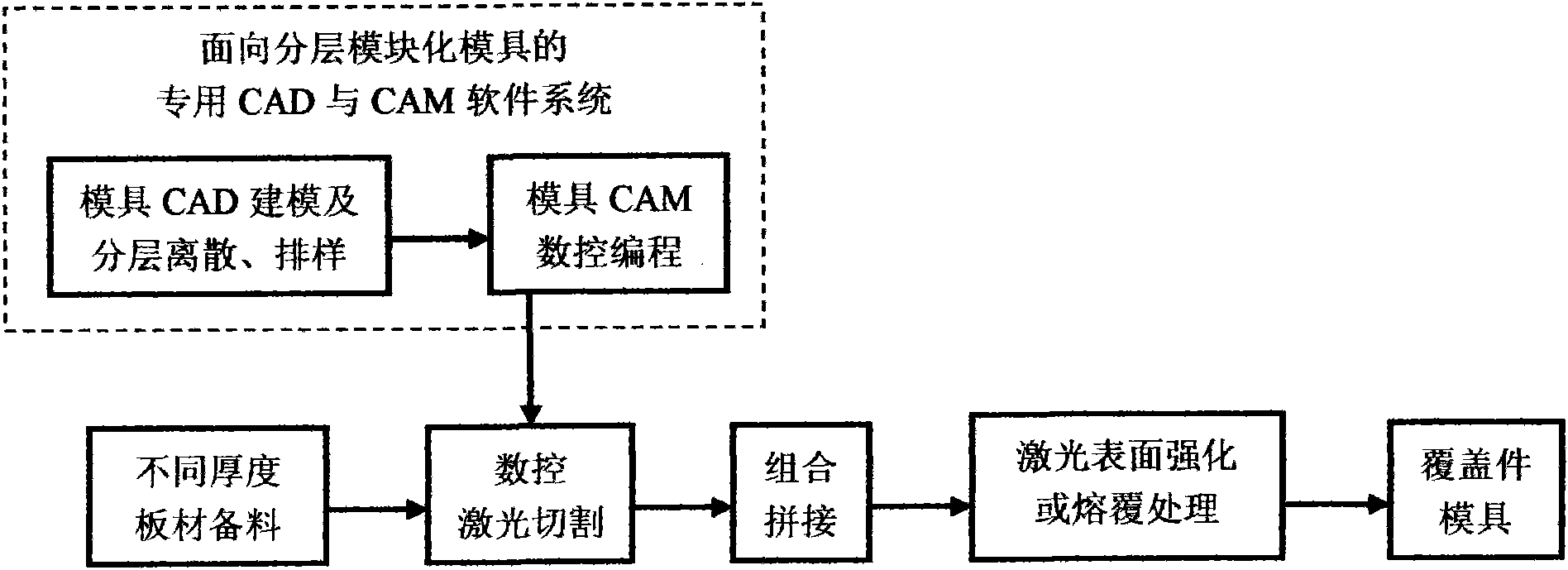

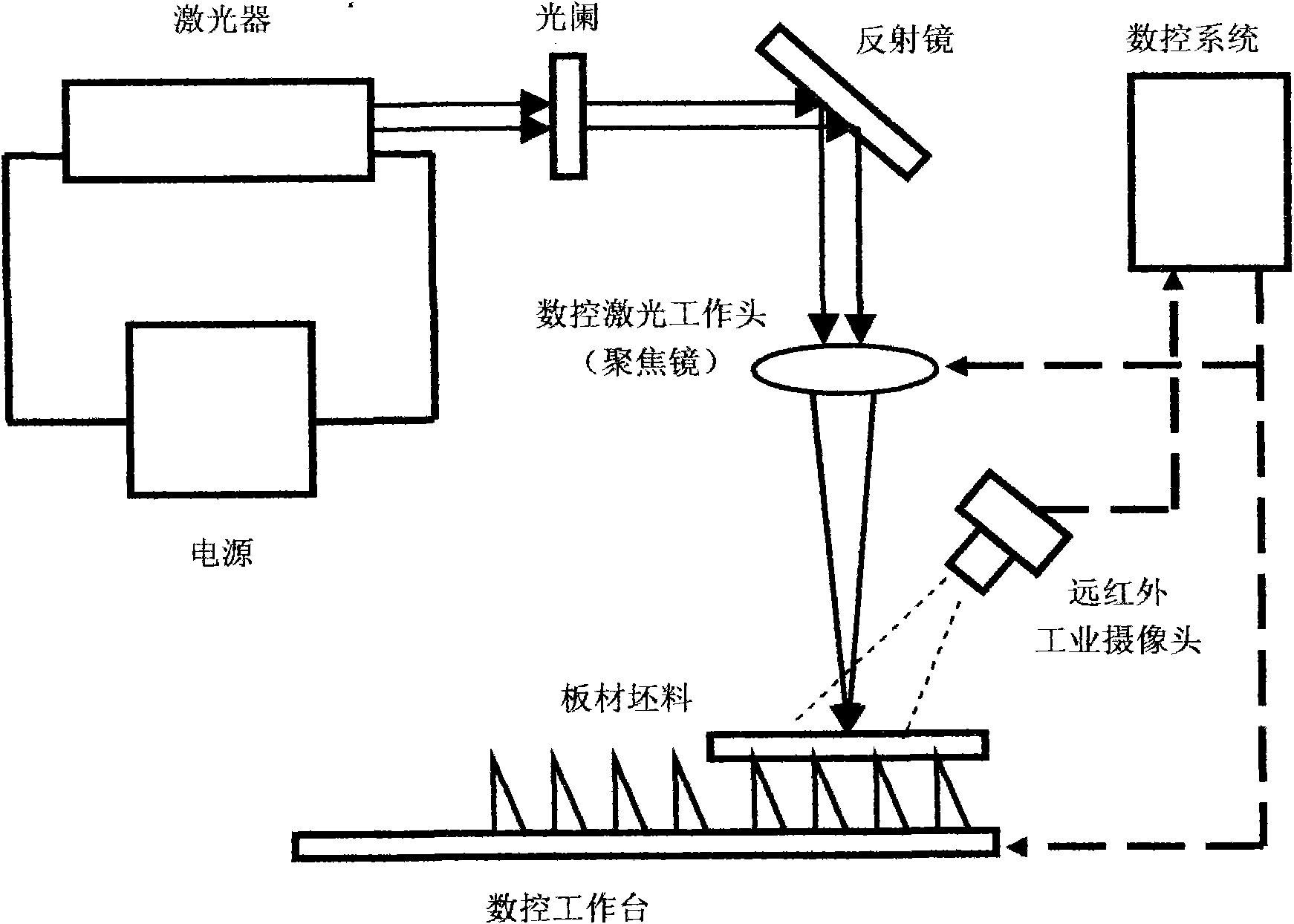

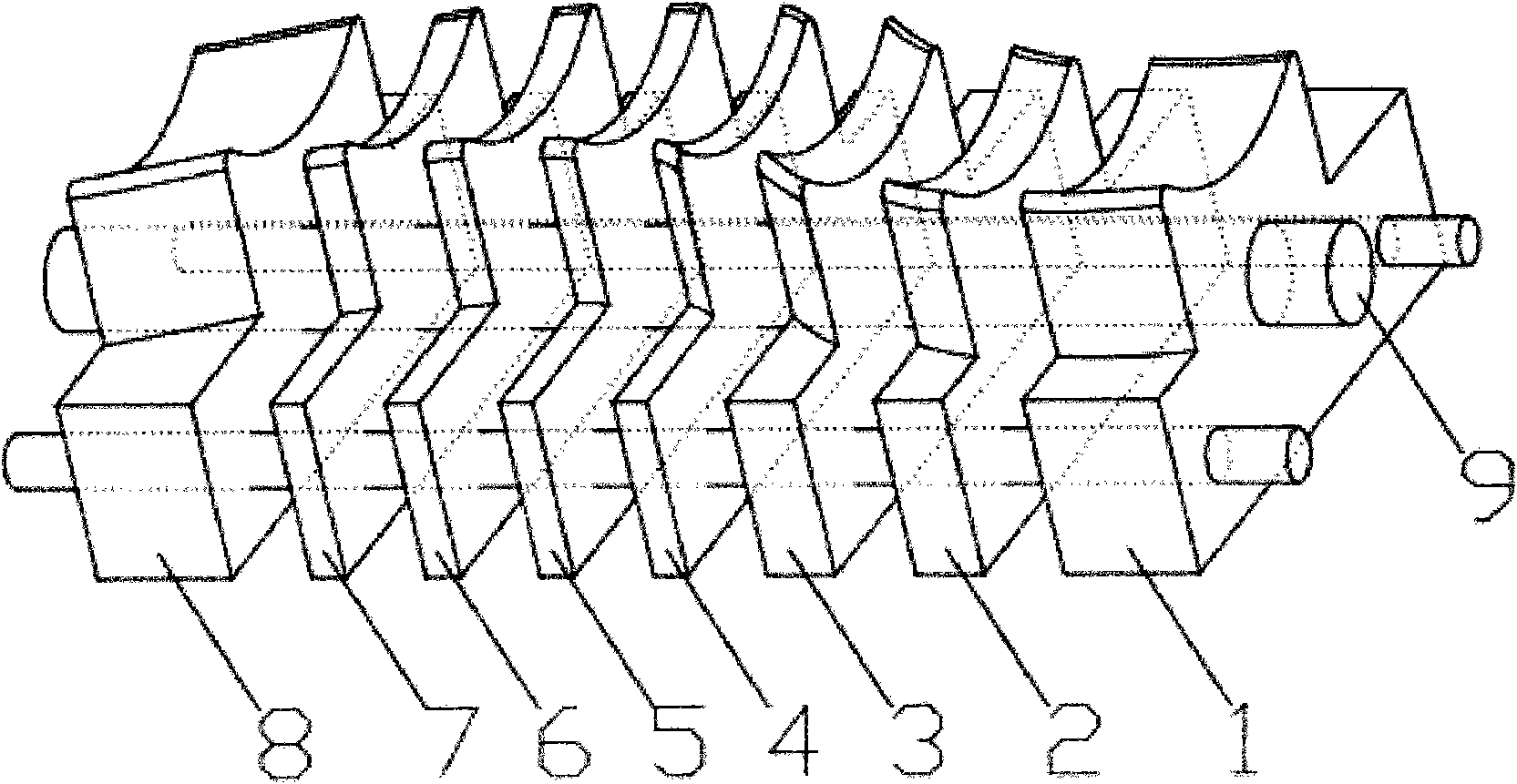

Quick and high-precision method for manufacturing layered modular die based on laser combination processing technology

InactiveCN102152009BShorten the processing cycleReduce processing costsLaser beam welding apparatusModular compositionEngineering

The invention discloses a quick and high-precision method for manufacturing a layered modular automotive panel die based on a laser combination processing technology. In the method, the quick and high-precision manufacturing for the automotive panel die is realized by mainly using a laser cutting processing technology and secondarily using a laser surface strengthening and cladding technology in combination with a layered modular die structure design method, so a quick and economic technology supporting measure is provided for trial-manufacturing of sample automobiles and panel dies during novel automobile type development. The method comprises the following processes of layering and cutting the die, positioning and connecting a modular combination, strengthening and cladding the laser surface and the like so as to finally form the layered modular automotive panel die on a partial key part; the material is in a functional gradient distribution from outside to inside; and the various structural layers have different mechanical performance and functions, so the whole performance requirement of the die can be guaranteed, the process is simplified and the cost is reduced. By the method, samples can be provided for trial-manufacturing of 200 sample automobiles; at the same time, sufficiently reliable experimentally checked design data can be provided for steel dies for normal production.

Owner:卢远志

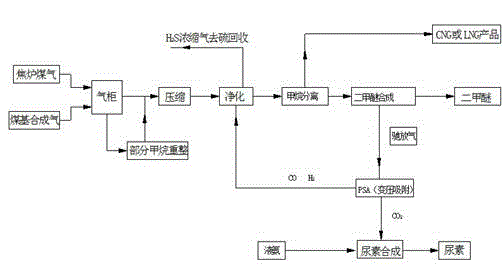

Method for producing dimethyl ether

ActiveCN104945229AImprove gas utilizationSolve the need for carbon supplementationUrea derivatives preparationProductsCoke ovenGas holder

A method for producing dimethyl ether comprises the steps that coke oven gas and coal-based synthesis gas are fed into a gas holder to form a gas mixture, reforming is conducted on one part of the gas mixture through methane, the reformed gas mixture is mixed with the rest of the gas mixture to form crude feed gas, purification is conducted on the compressed crude feed gas, desulphurizing and recycling are conducted on removed hydrogen sulfide, methane separation is conducted on the purified crude feed gas to obtain net feed gas, separated methane is made into liquefied natural gas products, dimethyl ether synthesis is conducted on the net feed gas to obtain the dimethyl ether, separation is conducted on purge gas produced after the dimethyl ether synthesis is conducted through pressure swing adsorption, separated CO and H2 return to the purification process, and urea synthesis is conducted on separated CO2 and liquid ammonia to obtain urea. The method for producing the dimethyl ether has the advantages that products are diversified, the utilization rate of the feed gas is increased, and the production cost of the dimethyl ether is reduced.

Owner:SEDIN ENG

Method for machining '8'-shaped grid

InactiveCN102896259AGuarantee the shape of the facadeEasy to operateFencing wireEngineeringAssembly line

The invention discloses a method for machining a '8'-shaped grid. The method is characterized by comprising the following steps of: a. bending a reinforcing steel bar into a rectangle, and welding the ends of the reinforcing steel bar to form a rectangular reinforcing steel bar with a closed structure; b. horizontally stamping the two long sides of the rectangular reinforcing steel bar to form a '8'-shaped reinforcing steel bar; and c. vertically stamping the middle part of the '8'-shaped reinforcing steel bar so that the middle part of the '8'-shaped reinforcing steel bar sinks to form an inverted trapezoidal concave part. The method has the beneficial effects of simpleness in operation and process, needing fewer welding joints during mechanical operation, guaranteeing the shape of the '8'-shaped vertical surface, needing less labor force, realizing assembly line work, improving the machining efficiency and saving cost.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

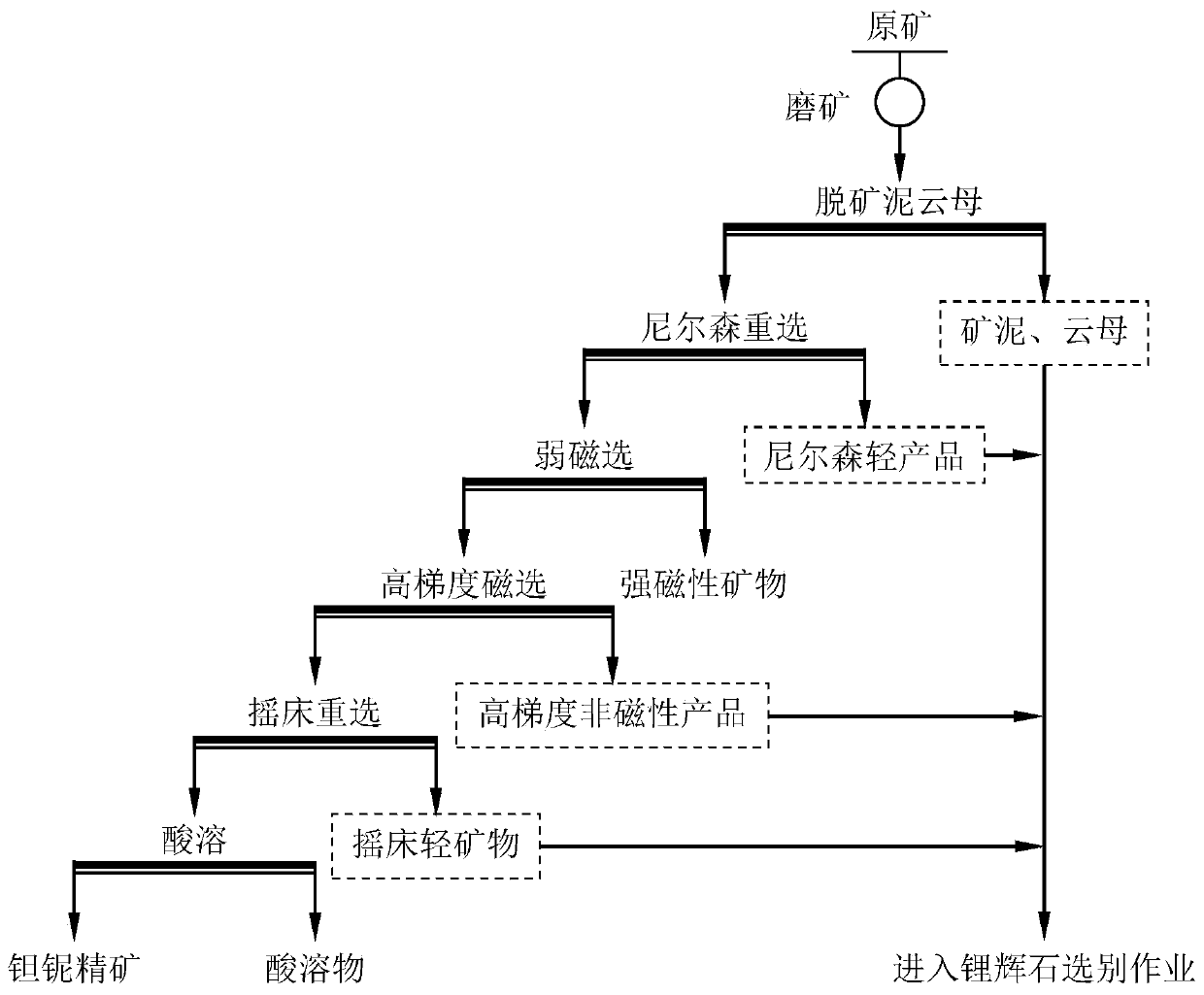

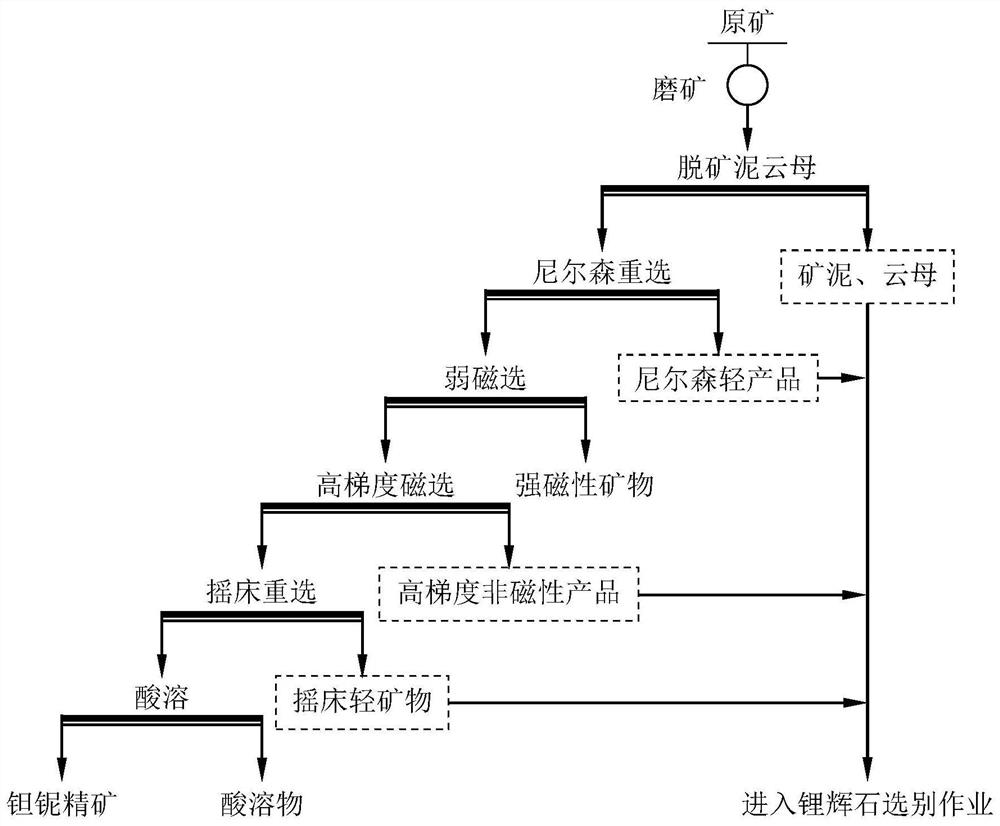

Effective recycle technology for associated niobium and tantalum of rare metal ores

ActiveCN110694787AHigh recycling indexReduce in quantityProcess efficiency improvementWet separationNiobiumSlurry

The invention discloses an effective recycle technology for associated niobium and tantalum of rare metal ores. The method comprises the following steps of 1, ore grinding; 2, slurry and mica removaloperation; 3, gravity concentration through a Knelson concentrator; 4, low intensity magnetic separation; 5, high gradient magnetic separation; 6, gravity concentration through a shaking table; 7, acid solution. Therefore, niobium and tantalum concentrate and acid-soluble substances are obtained. Compared with the prior art, the technology has the advantages that the defect of comprehensive recycle for associated niobium and tantalum minerals in rare metal spodumene ores in the prior art is overcome, and a dressing and smelting recycle technology which needs a small number of devices with small specifications and is low in energy consumption, small in occupation area, monotonous in process, simple in management, stable in process and high in niobium and tantalum recycle index is provided.

Owner:四川省地质矿产勘查开发局成都综合岩矿测试中心

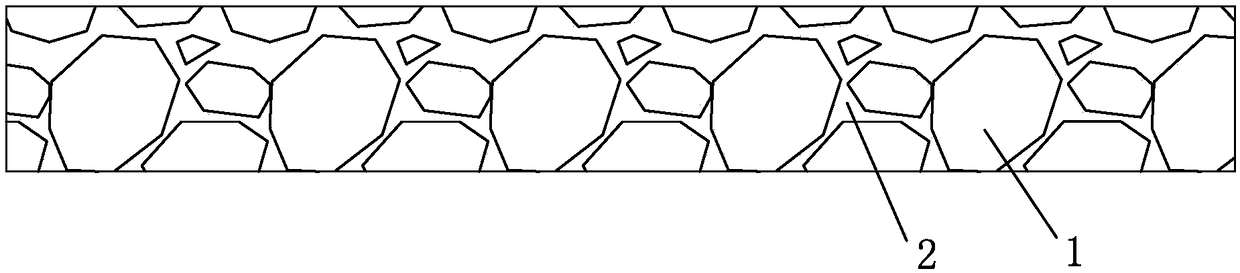

Plastic surface layer of elastic bead track for athletic running

PendingCN108149543AIncrease frictionNot easy to fall offPaving gutters/kerbsGround pavingsSurface layerAdhesive

The invention relates to a surface layer material of an athletic field, and aims to provide a plastic surface layer of an elastic bead track for athletic running. The plastic surface layer has the characteristics of good friction performance, excellent impact and absorption property, firm structure, excellent durability, water permeability and air permeability. According to the technical scheme, the plastic surface layer of the elastic bead track for athletic running comprises a plurality of near-spherical macromolecular elastic body beads, and is characterized in that the near-spherical macromolecular elastic body beads are piled up to form the plastic surface layer with a certain thickness, the adjacent elastic body beads are connected one another integrally through adhesives of portionswhich are in contact with one another, or the portions which are in contact with one another are fused and adhered integrally; and the other portions form irregular hollowed-out gaps.

Owner:杭州格林康体科技有限公司

An effective recovery process of associated niobium and tantalum in rare metal ores

ActiveCN110694787BHigh recycling indexReduce in quantityProcess efficiency improvementWet separationNiobiumAcid dissolution

The invention discloses an effective recovery process of rare metal ore associated niobium and tantalum. The steps of the method are as follows: step 1. ore grinding; step 2. demineralization mud mica operation; step 3. Nelson concentrator re-election; step 4. magnetic field weakening Election; step 5. high-gradient magnetic separation; step 6. shaker gravity separation; step 7. acid dissolution to obtain niobium tantalum concentrate and acid soluble matter. Compared with the prior art, the present invention aims at the deficiencies of the prior art in the comprehensive recovery of associated niobium and tantalum minerals in rare metal spodumene mines, and provides a device with a small number of equipment, small equipment specifications, low energy consumption, and an Small size, single process, simple management, stable process, high niobium and tantalum recovery index of dressing and smelting recovery process.

Owner:四川省地质矿产勘查开发局成都综合岩矿测试中心

A method for refining and purifying caprolactam

ActiveCN107778244BEmission reductionGood chromaLactams separation/purificationDistillationProcess engineering

Owner:SHAANXI KEYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING TECH

A method for harmless separation of aluminum electrolysis waste cathode carbon blocks

ActiveCN108728867BEfficient separationSolve environmental problemsAluminium fluoridesAluminium electrolysisPhysical chemistry

The invention discloses a method for harmless separation of aluminum electrolysis waste cathode carbon blocks, which belongs to the technical field of inorganic chemistry. The main steps include: S1, crush and screen the aluminum electrolysis waste cathode carbon blocks to obtain carbon block particles; S2, prepare an acid solution with a concentration of 1 mol / L for later use; S3, put the carbon block particles obtained in step S1 into step S2. The prepared acid solution is leached under heating and stirring conditions to obtain a leaching solution; S4. Filter the leaching solution obtained in step S3 to separate the filtrate and filter residue. The filter residue is washed and dried to obtain a carbon powder product; S5. Add a salt solution to the filtrate of step S4 for fluorine precipitation to obtain a fluorine precipitation solution; S6. Filter the fluorine precipitation solution of step S5 to separate the filtrate and filter cake. The filter cake is washed and dried to obtain Basic metal fluoride products. The invention can obtain aluminum electrolyte with higher purity suitable for industrial electrolytic aluminum production, and recover fluorine salt, and no waste is generated in the whole process.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com