A method for extracting lithium salt in aluminum electrolyte by fluorination roasting and acid leaching

An aluminum electrolyte and acid leaching technology, which is applied in the direction of improving process efficiency, can solve problems such as reduced service life of electrolytic cells, reduced alumina solubility, and damaged carbon materials, and achieves low extraction costs, reduced energy consumption, and improved comprehensive performance. horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The method of utilizing fluorination roasting and acid leaching to extract the lithium salt in the aluminum electrolyte of this embodiment comprises the following steps:

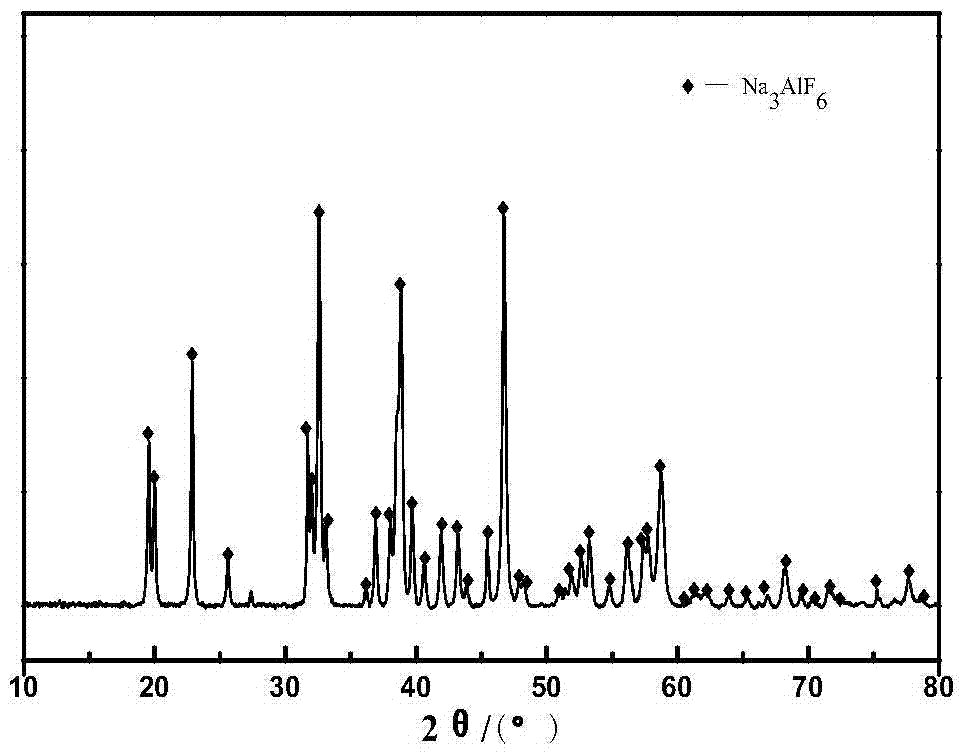

[0044] Step 1: Pulverize 10 g of aluminum electrolyte containing lithium, add sodium fluoride to obtain a mixed material, and mix evenly, wherein the molar ratio of sodium fluoride to aluminum fluoride in the mixed material is 3:1;

[0045] Step 2: heat the mixed material at 400°C for 3 hours; after cooling down to room temperature, pulverize the mixed material;

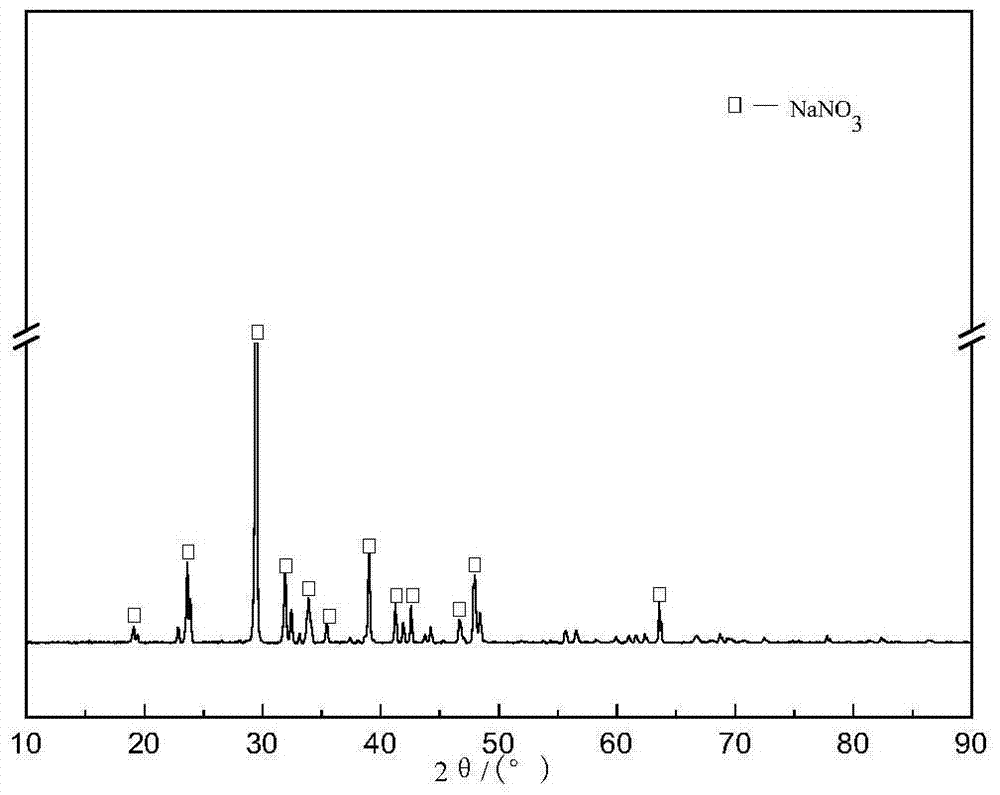

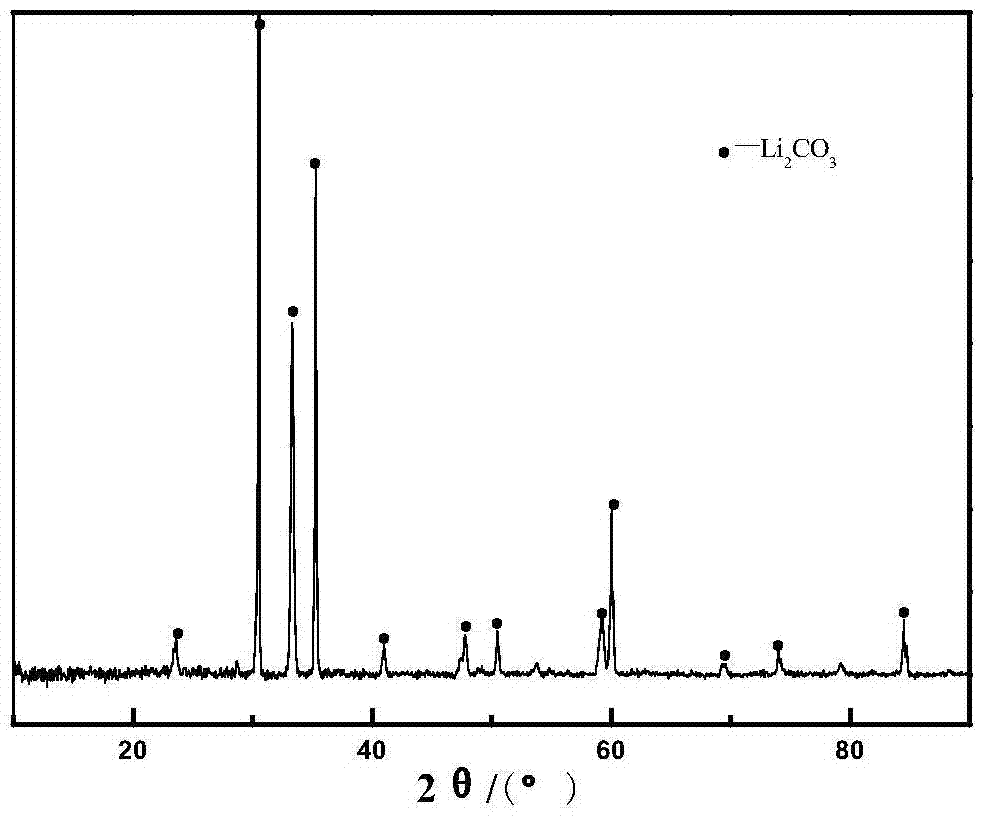

[0046] Step 3:

[0047] (1) At 20°C, add HNO with a concentration of 14mol / L and a volume of 100ml to the mixed material 3 Solution, wherein, the quality of the aluminum electrolyte: the volume of the acid solution = 100g / L; the stirring speed is 100r / min, stirring for 30min, during the stirring process, add water to the reaction solution to keep the volume of the reaction solution constant, filter to obtain a filtrate and primary filtrate...

Embodiment 2

[0059] The method of utilizing fluorination roasting and acid leaching to extract the lithium salt in the aluminum electrolyte of this embodiment comprises the following steps:

[0060] Step 1: Grinding 5 g of aluminum electrolyte containing lithium, adding sodium fluoride to obtain a mixed material, and mixing evenly, wherein the molar ratio of sodium fluoride to aluminum fluoride in the mixed material is 3.5:1;

[0061] Step 2: heat the mixed material at 1000°C for 2 hours; after cooling down to room temperature, pulverize the mixed material;

[0062] Step 3:

[0063] (1) At 100°C, add HNO with a concentration of 14mol / L and a volume of 50ml to the mixed material 3 Solution, wherein, the quality of the aluminum electrolyte: the volume of the acid solution = 100g / L; the stirring speed is 300r / min, stirring for 180min, during the stirring process, add water to the reaction solution to keep the volume of the reaction solution constant, filter to obtain a filtrate and primary ...

Embodiment 3

[0075] The method of utilizing fluorination roasting and acid leaching to extract the lithium salt in the aluminum electrolyte of this embodiment comprises the following steps:

[0076] Step 1: Pulverize 65g of aluminum electrolyte containing lithium, add sodium fluoride to obtain a mixed material, and mix evenly, wherein the molar ratio of sodium fluoride to aluminum fluoride in the mixed material is 4:1;

[0077] Step 2: heat the mixed material at 500°C for 3 hours; after cooling down to room temperature, crush the mixed material;

[0078] Step 3:

[0079] (1) At 80°C, add H with a concentration of 9mol / L and a volume of 1000ml to the mixed material 2 SO 4 Solution, wherein, the quality of the aluminum electrolyte: the volume of the acid solution = 65g / L; the stirring speed is 250r / min, stirring for 120min, during the stirring process, add water to the reaction solution to keep the volume of the reaction solution constant, filter to obtain a filtrate and primary filtrate;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com