Method for preparing silicon tetrafluoride through pyrolysis of sodium fluosilicate in rotary reaction furnace

A technology of sodium fluorosilicate and silicon tetrafluoride, which is applied in the direction of silicon halide compounds, halosilanes, etc., can solve the problems that the products are not easy to handle, silicon tetrafluoride has many impurities, complex components, etc., and can solve the problem of waste gas treatment Difficult, low content of impurity ingredients, single ingredient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

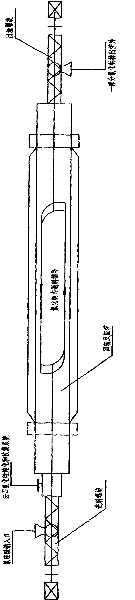

Image

Examples

Embodiment 1

[0029] Sodium fluorosilicate is sent to the sodium fluorosilicate silo through the hopper elevator; according to the amount of feed, it will be automatically discharged into the powder hopper scale through the screw. Precisely measured by a weighing instrument, put 100kg of sodium fluorosilicate into a rotary calciner for drying, at 250°C and a slight negative pressure of 20mm H 2 Drying and internal dehydration are carried out between O, and after drying, it is cooled by the mixing screw and sent to the feeding screw of the rotary reaction furnace. of sodium fluoride mixed. At 500°C (material temperature), micro-negative pressure 15mm H 2 The reaction is carried out in the reaction furnace under the condition of O to generate sodium fluoride (NaF) and silicon tetrafluoride (SiF 4 )gas. The silicon tetrafluoride gas is generated at a temperature of 300°C, enters the gas duct of the furnace head of the reaction furnace, and passes through the dust collector to remove the dus...

Embodiment 2

[0034](1) Dry and heat-treat 100kg of sodium fluorosilicate in a rotary calciner at 260°C for 90 minutes, and control the negative pressure at 15mm H 2 O.

[0035] (2) Before the sodium fluorosilicate enters the rotary reaction furnace, it is mixed with 100kg of inert auxiliary agent silicon dioxide, and then enters the rotary reaction furnace for cracking.

[0036] (3) Send the dried sodium fluorosilicate into a rotary reaction furnace, react at 700°C (material temperature) for 1 hour, and thermally crack to obtain silicon tetrafluoride and sodium fluoride. The negative pressure value is controlled at 10mm H 2 O.

[0037] (4) The generated silicon tetrafluoride gas is dedusted, cooled, dried, compressed, and high-purity silicon tetrafluoride gas is collected.

Embodiment 3

[0039] (1) Dry and heat-treat 100kg of sodium fluorosilicate in a rotary calciner at 280°C for 65 minutes, and control the negative pressure at 10mm H 2 0.

[0040] (2) Before the sodium fluorosilicate enters the rotary reactor, it is mixed with 150kg of inert additive alumina, and then enters the rotary reactor for cracking.

[0041] (3) Send the dried sodium fluorosilicate into a rotary reaction furnace, react at 630°C (material temperature) for 85 minutes, and thermally crack to obtain silicon tetrafluoride and sodium fluoride. The negative pressure value is controlled at 15mm H 2 O.

[0042] (4) The generated silicon tetrafluoride gas is dedusted, cooled, dried, compressed, and high-purity silicon tetrafluoride gas is collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com